- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

720*660*850 mm

-

Weight:

-

800 KG

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

Rock Crusher Machine

-

Keyword:

-

Jaw Crusher Crusher Jaw

-

The Machines classification:

-

Small Stone Machine

-

Raw material:

-

Stones Rocks Ores

-

Applicaton:

-

Stone Process

-

Processed Materials:

-

200 Kinds Materials(<300 Mpa)

-

Advantage:

-

High Effiency

-

Function:

-

Mining Crusher Equipment

-

Spare parts supply:

-

Anytime

-

Quality:

-

Advanced Technology

Quick Details

-

Application:

-

stone,ore,coal,sand

-

Place of Origin:

-

HEN

-

Brand Name:

-

Huansheng

-

Dimension(L*W*H):

-

720*660*850 mm

-

Weight:

-

800 KG

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

Rock Crusher Machine

-

Keyword:

-

Jaw Crusher Crusher Jaw

-

The Machines classification:

-

Small Stone Machine

-

Raw material:

-

Stones Rocks Ores

-

Applicaton:

-

Stone Process

-

Processed Materials:

-

200 Kinds Materials(<300 Mpa)

-

Advantage:

-

High Effiency

-

Function:

-

Mining Crusher Equipment

-

Spare parts supply:

-

Anytime

-

Quality:

-

Advanced Technology

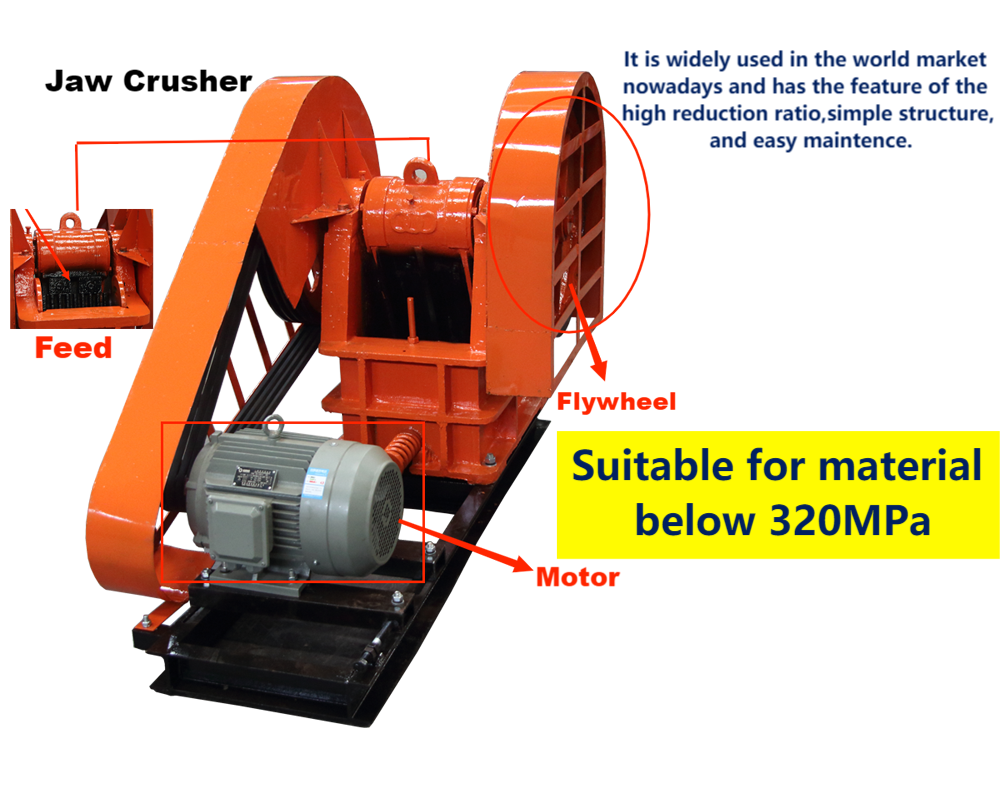

Product Display

The

stone

crusher

is mainly used for rough and moderate broken operations of various ore materials those compressive strength are not more than 320 MPa. This crusher has features of high broken ratio, uniform product size, simple structure, reliable operation, convenient maintenance, low operating costs etc, which is widely used in mining, smelting, building, roads, railways, water conservancy and chemical industry.

Features of Stone Jaw Crusher:

1.High capacity

2.High reliability

3.Adjustable for easy wear parts

4.over-loading protection

5.simple structure and easy to operate

6.Easy replacement of wear and spare parts

7.Less costly and Easy to install

8

.Wide range of choices

9.wearable parts made of high manganese steel

Product Parameters

The advantages of our Stone Crusher:

1.superior quality.

2.reasonable price.

3.one year guarantee.

4.our after-sales service team act immediately on receiving your reports.

5.providing high quality spare parts with low prices in order to appreciate your trust on our factory.

|

Model:

PE. ** |

Max feed

size(mm) |

Discharge

opening range(mm) |

Processing

capacity (t/h) |

Eccentic

shaft speed(r/min) |

Power

(kw) |

Weight

(t) |

Dimension

(mm) |

|

150*250

|

150*250

|

10-40

|

1-3

|

250

|

5.5

|

0.8

|

720*660*850

|

|

200*300

|

200*300

|

15-50

|

2-6

|

260

|

7.5

|

1.2

|

910*750*990

|

|

200*350

|

200*350

|

18-70

|

3-10

|

260

|

11

|

1.5

|

1000*870*990

|

|

250*400

|

250*400

|

20-60

|

5-20

|

300

|

15

|

2.8

|

1300*1090*1270

|

|

400*600

|

400*600

|

40-100

|

16-60

|

275

|

30

|

7

|

1730*1730*1630

|

|

500*750

|

500*750

|

50-100

|

40-110

|

275

|

55

|

12

|

1980*2080*1870

|

|

600*750

|

600*750

|

150-200

|

80-240

|

275

|

55

|

15.8

|

2070*2000*1920

|

|

600*900II

|

600*900II

|

65-160

|

50-180

|

250

|

55

|

17

|

2190*2206*2300

|

|

750*1060

|

750*1060

|

80-140

|

110-320

|

250

|

110

|

29

|

2660*2430*2800

|

|

800*1060

|

800*1060

|

130-190

|

130-330

|

250

|

110

|

29.8

|

2710*2430*2800

|

|

830*1060

|

830*1060

|

160-220

|

150-226

|

250

|

110

|

30.7

|

2740*2430*2800

|

|

870*1060

|

870*1060

|

200-260

|

190-336

|

250

|

110

|

31.5

|

2810*2430*2800

|

|

900*1060

|

900*1060

|

230-290

|

230-390

|

250

|

110

|

33

|

2870*2420*2940

|

|

900*1200

|

900*1200

|

95-165

|

240-450

|

200

|

110

|

52

|

3380*2870*3300

|

|

1000*1200

|

1000*1200

|

195-265

|

315-500

|

200

|

110

|

55

|

3480*2876*3300

|

|

1200*1500

|

1200*1500

|

150-350

|

400-800

|

180

|

160

|

100.9

|

4200*3300*3500

|

|

1500*1800

|

1500*1800

|

220-350

|

500-1000

|

180

|

280

|

122

|

5160*3660*4248

|

|

1800*2100

|

1800*2100

|

300-400

|

600-1200

|

180

|

400

|

150.6

|

6120*4013*4716

|

Product Details

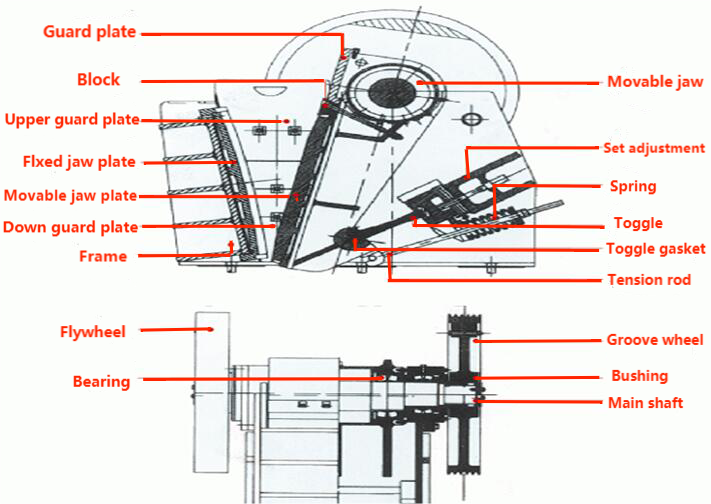

Working principle of Stone Jaw Crusher:

By using motor as its power, the eccentric shaft is driven by the belt and belt wheel to make the movable jaw move up and down. When the movable jar ascends, the angle between the toggle plate and it becomes larger, push it toward the fixed jaw plate, reaching the purpose of crushing the materials. When the movable jaw descends, the angle becomes smaller, in the action of draw bar and spring, depart from the fixed jaw plate and discharge the materials, when the pressure rises to the strength beyond which the materials can bear, the crushing happens. Otherwise, when the fixed jaw swings in the opposite direction departing from the fixed jaw, the materials move downward by the self weight. Every periodical movement of the movable jaw will make the crushing effect on the materials, and send them a distance downward. The crushed materials will be discharged through the discharging opening after several periods.

Application scenario

The Stone Crusher mainly consists of Vibrating Feeder, Jaw Crusher/Cone Crusher/ Impact Crusher, add vibrating Screen, Belt Conveyor and Control System, etc.It is completely capable to crush and screen limestone, marble, granite, basalt, river gravel and other hard stone materials, suitable for construction and building industry.We can provide optimum and most economical solutions according to your' requirements.

Packing & Shipping

The mobile crushing station is so large that it is suitable for container transportation. We have more than 20 years of export experience and have freight forwarders we often cooperate with, which will allow you to spend less on freight.

Hot Searches