- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

11800 KG

-

Product Name:

-

Mini Hydraulic VSI Gravel Powder Sand Making Machine for sale

-

Color:

-

Required

-

Price:

-

Negotation

-

Model:

-

Variety

-

Function:

-

Mining Crusher Equipment

-

Installation:

-

Engineer Guide

-

The Machines classification:

-

Building Stone Production Line

-

Applicaton:

-

sand making

-

Quality:

-

Advanced Technology

-

Spare parts supply:

-

12 Months Guarantee

Quick Details

-

Application:

-

product sand

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yuxiang

-

Weight:

-

11800 KG

-

Product Name:

-

Mini Hydraulic VSI Gravel Powder Sand Making Machine for sale

-

Color:

-

Required

-

Price:

-

Negotation

-

Model:

-

Variety

-

Function:

-

Mining Crusher Equipment

-

Installation:

-

Engineer Guide

-

The Machines classification:

-

Building Stone Production Line

-

Applicaton:

-

sand making

-

Quality:

-

Advanced Technology

-

Spare parts supply:

-

12 Months Guarantee

Mini Hydraulic VSI Gravel Powder Sand Making Machine for sale

>Products Description<

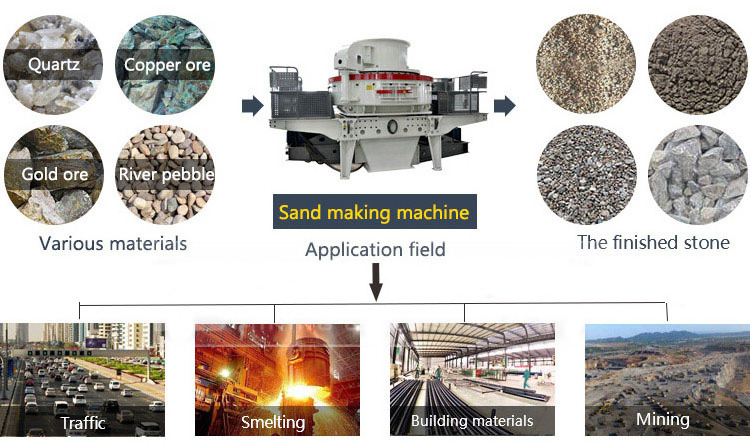

VSI sand making machine is a highly efficient crushing machine which introduces "stone to stone" and "stone to iron" crushing principle. Combining domestic actual sand making condition, this crusher is designed as a highly efficient crushing machine of domestic and international standard. This crusher is widely used to crush various rocks, grinding materials, refractory, clinker, quartz, iron ore, concrete aggregate, etc.

Main Features:

1. Unique structure and stable operation.

2. Low energy consumption, large capacity and crushing ratio.

3. Perfect cubic product size and high bulk density.

4. Less spare parts. Spare parts are made of special hard material, which make them of long service life and easy to change.

2. Low energy consumption, large capacity and crushing ratio.

3. Perfect cubic product size and high bulk density.

4. Less spare parts. Spare parts are made of special hard material, which make them of long service life and easy to change.

>Details Images<

>>Product Paramenters<<

|

Model

|

|

VSI-7611

|

VSI-8518

|

VSI-9526

|

VSI-1140

|

VSI-1145

|

|||||

|

Capacity(t/h)

|

Cascade and center feeding

|

120-180

|

200-260

|

300-360

|

450-520

|

490-600

|

|||||

|

|

Center Feeding

|

60-90

|

100-130

|

150-190

|

225-260

|

250-310

|

|||||

|

Feeding Size

(mm)

|

Soft Material

|

<35

|

<40

|

<45

|

<50

|

<50

|

|||||

|

|

Hard Material

|

<30

|

<35

|

<40

|

<45

|

<45

|

|||||

|

Rotation Speed(r/min)

|

|

1700-1890

|

1520-1690

|

1360-1510

|

1180-1310

|

1180-1280

|

|||||

|

Power of the Double Motor(kw)

|

|

110-150

|

180-220

|

264-320

|

400-440

|

440-520

|

|||||

|

Overall dimension L*W*H(mm)

|

|

3600*2248*

2533

|

4378*2350*

2667

|

4640*2650*

2800

|

5570*2900*

3000

|

5500*2700*

3300

|

|||||

|

Weight(t)

|

|

11.8

|

14.5

|

17.8

|

25.6

|

26

|

|||||

|

Power Source

|

|

380v 50hz

|

|

|

|

|

|||||

>Advantages of Sand Making Machine<

Display of sand making machine parts

Working Principle

Sand Making Machine (also known as "Sand Maker") has two feed modes – "feed at center" and "feed at center & sides". As for the former mode "feed at center", materials at the feed hopper firstly pass through the central hole into the high-speed spinning rotor. In the rotor, materials are fully accelerated and thrown outwards from the launching port to collide with a part of materials that freely fall after rebound. Next, materials hit the surrounding vortex material liner (or the impact block) inside the vortex chamber together. In the chamber, materials are bounced to the top of crushing chamber firstly and then change their

direction by moving downwards to form a material curtain with materials emitted from the runner impeller. Finally, finished products are discharged from the bottom discharge opening. As for the latter mode "feed at center & sides", firstly, materials at the feed hopper pass through the circular hole. Then, materials are divided into two parts by the distributing tray. One part of materials enter the high-speed rotating impeller while the other part of materials fall from all sides of the tray. Materials in the impeller would be accelerated rapidly and thrown outwards at a high speed to collide with materials falling from all sides of

the tray. Next, all materials hit the surrounding vortex material liner (or the impact block) inside the vortex chamber together. In the chamber, materials are bounced to the top of crushing chamber firstly and then change their direction by moving downwards to form a material curtain with materials emitted from the runner of impeller. Finally, finished products are discharged from the bottom discharge opening.

direction by moving downwards to form a material curtain with materials emitted from the runner impeller. Finally, finished products are discharged from the bottom discharge opening. As for the latter mode "feed at center & sides", firstly, materials at the feed hopper pass through the circular hole. Then, materials are divided into two parts by the distributing tray. One part of materials enter the high-speed rotating impeller while the other part of materials fall from all sides of the tray. Materials in the impeller would be accelerated rapidly and thrown outwards at a high speed to collide with materials falling from all sides of

the tray. Next, all materials hit the surrounding vortex material liner (or the impact block) inside the vortex chamber together. In the chamber, materials are bounced to the top of crushing chamber firstly and then change their direction by moving downwards to form a material curtain with materials emitted from the runner of impeller. Finally, finished products are discharged from the bottom discharge opening.

>Recommend Products<

>Product packaging<

>Why Choose Us<

Hot Searches