- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

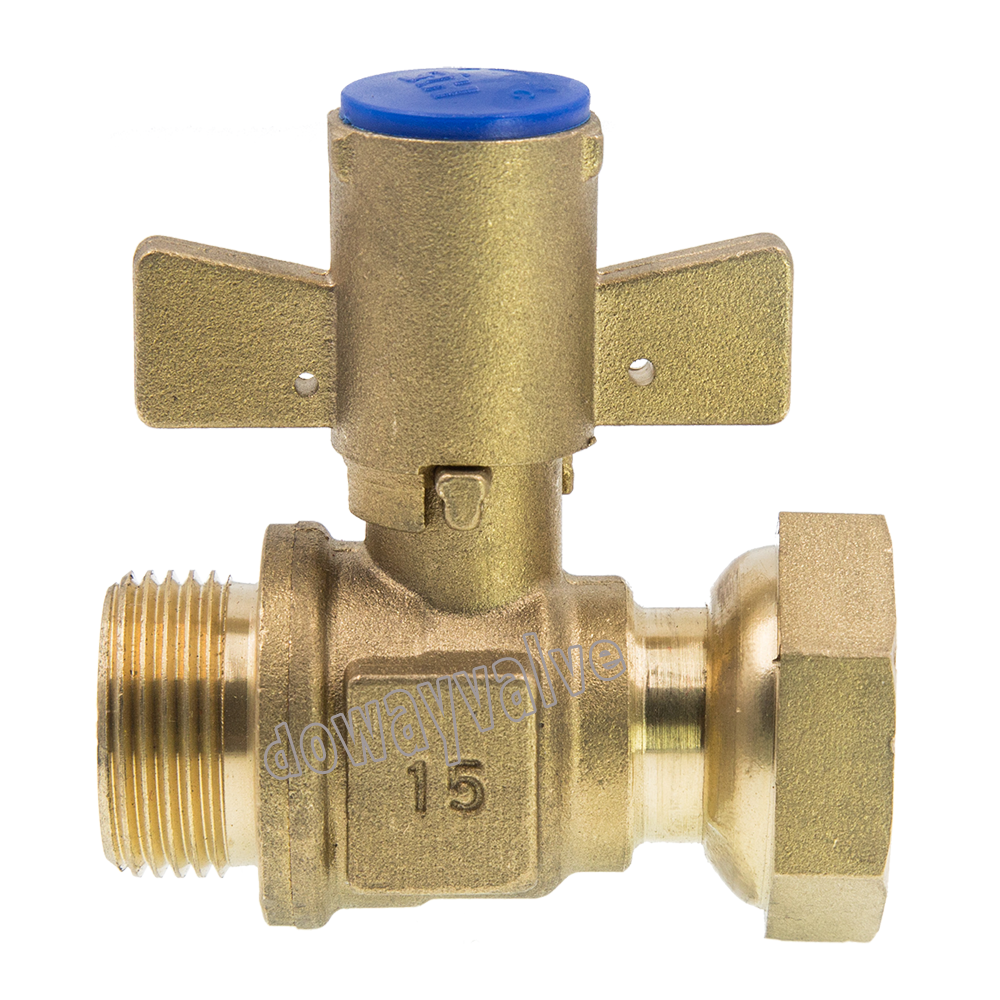

DW Brass lockable ball valve

-

HS Code:

-

8481804090

Quick Details

-

Port Size:

-

1/2",3/4",1"

-

Place of Origin:

-

Zhejiang, China

-

Model Number:

-

DW310 Brass lockable ball valve

-

Brand Name:

-

DW Brass lockable ball valve

-

HS Code:

-

8481804090

- Product Description :

- Brass Lockable ball valve,Brass lever handle

- Material: Forged Brass ( CW617N, CW614 ,CW602N,ASTM C37700)

- Size : DN15x3/4"x PE20mm, DN15x3/4"x PE25mm, DN20x1"x PE25mm, DN20x1"xPE32mm

-

Thread standard : Free Nut according to ISO228, ISO7/1, DIN2999/DECA fittings

For the handle, it could be changed to magnetic Type, Brass Handle, or Zinc Alloy Handle -

Package details : Each valve by one polybag, inner box, Cartons with pallets

- Technical Specification:

- Working pressure : 1.6Mpa

- Tested Pressure : 2.0Mpa

- Working medium : Water, oil, gas

- Working temperature : -20° C≤ T≤ 120° C

- Installation Instruction:

| 1 | Before Installing the valves, clean and remove any objests from the pipes | |||||||

| 2 | Ensure both connection pipes either side of valves and aligned | |||||||

| 3 | Ensure that two sections of the pipe match, and the valves until will not accept any | |||||||

| gaps, any distroy in the pipes may affect the tighting of the connection, The work | ||||||||

| of the vales and can even casue a rupture. To be sure, place the kit in position to | ||||||||

| ensure the assembling will work | ||||||||

| 4 | Before starting the fittings, ensure the threads and tappings are clean | |||||||

| 5 | If secton of pipes have not their final support in that place, They can be temporatily | |||||||

| fixed, In order to avoid unnecessary strain on the valves | ||||||||

| 6 | The theoretical lenghts gived by ISO7/1 for the tapping are typically longer than | |||||||

| required, The length of the thread should be limited, and check that the end of tube | ||||||||

| does not press right up to the head of the thread | ||||||||

| 7 | For the sealing assembly valves pipes, it is essential to use products that are | |||||||

| compatible with the requirements of the clean water meter | ||||||||

| 8 | Position the pipe clips on both side of the valves | |||||||

| 9 | If mounting on an air conditioning with Per tubing and hoses, it is is necessary | |||||||

| to support the tubes and hoses with the fixed to abvoid strain on valves | ||||||||

| 10 | When screwing the valves, ensure you only rotate on screws side by the 6 ended | |||||||

| side, Use an open ended spanner or an adjustable spanner and not a monkey | ||||||||

| wrench. Never use a vice to tighten the fixing of the valves | ||||||||

| 11 | Do not over tighten the valves, Do not block with any extensions as it may cause a | |||||||

| rupture or weekening of the forging strenght. The Torque force not more than 30Nm | ||||||||

- General Guidelings :

| 1 | Ensure that the valves to be used are appropriate for the condition of the installation | |||||||

| 2 | Be sure to have enough valve to be able to isolate the section of pipes as well as | |||||||

| the approciate equipment for maintenance and repair | ||||||||

| 3 | Ensure that valves to be installed are of correct strenght to be able to support the | |||||||

| capacity of their usage | ||||||||

| 4 | Installation of all circuits should ensure their function can be automatically tested on | |||||||

| a regular basis ( at least two times per year) | ||||||||

Water meter ball valve/lockable ball for water meter/Anti-theft Ball Valve

Brass forged body, brass ball chrome plated,, brass stem and brass handle. For water meter before or after water meter PTFE packing with free nut and DECA fittings.

Brass lockable ball valve for water meter with female thread, with brass body, anti-theft short or long handle.

Welcome to your inquiry anytime.