- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

LK-G2000

-

Voltage:

-

customized

-

Dimension(L*W*H):

-

6000*2500*4000mm

-

Year:

-

2023

-

Weight (KG):

-

25000 kg

-

Power (kW):

-

250kw

-

Type:

-

Tire Recycling System

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Waste Rubber Tyre Recycle Machine

-

capacity:

-

500kg-3000kg/h

-

feeding material:

-

waste tires

-

final product:

-

rubber blocks, rubber granules, rubber powder

-

Shippment:

-

By sea

-

Application:

-

Rubber Processing Machinery

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

hvst

-

Marketing Type:

-

New Product 2023

-

Model Number:

-

LK-G2000

-

Voltage:

-

customized

-

Dimension(L*W*H):

-

6000*2500*4000mm

-

Year:

-

2023

-

Weight (KG):

-

25000 kg

-

Power (kW):

-

250kw

-

Type:

-

Tire Recycling System

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Waste Rubber Tyre Recycle Machine

-

capacity:

-

500kg-3000kg/h

-

feeding material:

-

waste tires

-

final product:

-

rubber blocks, rubber granules, rubber powder

-

Shippment:

-

By sea

-

Application:

-

Rubber Processing Machinery

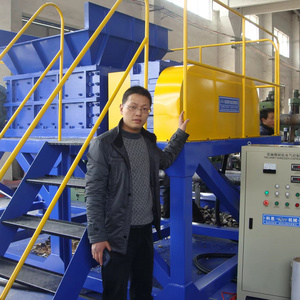

Factory price rubber granulator/waste tire recycling mahine

The Granulators are designed to grind the rubber mulch from the rasper into small granules as fine as 1mm. The granules are screened and re-circulated until the desired size is reached. Due to the design of the granulator and precise alignment of the blades, the granulator produces a very uniform cut and high quality granule. During the granulation process, 99% of the fiber is removed, leaving a contaminant free crumb rubber granulate ready to be further processed or sold.

|

Granulator

|

LK - G90

|

LK-G45

|

LK -G37

|

|

Motor specifications

|

Electric-Siemens

|

Electric-Siemens

|

Electric-Siemens

|

|

Power

|

90Kw

|

45KW

|

37KW

|

|

Voltage

|

As per request

|

As per request

|

As per request

|

|

cutting chamber L*W

|

742*1200

|

580*1000

|

580*800

|

|

Equipment dimensions

|

2150*2250*2950

|

1765*1900*2435

|

1765*1600*2435

|

|

Equipment weight

|

5600kg

|

3300kg

|

2950kg

|

|

Hopper opening L*W*H

|

895*1434*1160

|

602*994*916

|

602*794*916

|

|

Capacity

|

800-1500kg/H

|

500-800kg/H

|

300-500kg/H

|

|

Final product

|

1-6mm

|

1-6mm

|

1-6mm

|

☑ Adjustable knife clearance for optimizing the cutting function

☑ The knives can be reground multiple times on a “flat-bed” grinder ensuring long life and low operation costs

☑ Designed for quick and easy change of knives and screens

☑ The rotor is manufactured and designed for minimum wear

☑ Friction clutches protect the machine from material overload

☑ Hydraulically operated inlet hopper provides easy access to the cutting chamber for maintenance

☑ Screens with different hole sizes are available for flexible production

☑ Exchangeable wear parts give you a virtually indestructible machine

Applation

Raw materials:

Waste tires, rubber soles, waste pipes, rubber conveyor belts and other waste rubber products, of which waste tires are the most.

8 - 20 mesh

8-20 mesh, mainly used for runways, road cushions, sports pavements, etc

30-40 mesh

30-40 mesh, mainly used for reclaimed rubber, paving, producing rubber sheets

60-80 mesh

60-80 mesh, mainly used in automobile tires, rubber products, building materials

Product Introduction

|

Tire Shredder

|

|

|

|

Model

|

TS-800

|

|

|

Capacity

|

2~3 t/h

|

|

|

Output Size

|

50*50 mm

|

|

|

Blade Material

|

9Cr2Mo

|

|

|

Power

|

2*22 kW

|

|

|

Input Size (diameter)

|

800 mm

|

|

|

Blade quantity

|

16 pcs

|

|

|

Size

|

5.6*2*3.4 m

|

|

1.Tire shredder is a multi-functional shredder machine used for plastic recycling, tire recycling,metal recycling, and so on.it has double-shaft design, which consists of two big diameter shafts;16-30 pieces of blades; shredding drum; iron

frame; two motors and two reducers.

2.The thickness range of the crushing blade i50mm-150mm according to the tire type, output and final product.

3.The shredder can process OTR tires, big truck tires, car tires and so on.

|

Rasper (rubber mulching)

|

|

|

|

Model

|

LK-R90

|

|

|

Capacity

|

2000 kg/h

|

|

|

Cutting Chamber

|

550*1200 mm

|

|

|

Equipment Weight

|

5.5 tons

|

|

|

Power

|

90 kW

|

|

|

Hopper Opening

|

1182*700*1255 mm

|

|

|

Machine Size

|

1995*1980*4105 mm

|

|

|

Output Size

|

10~20 mm

|

|

|

Granulator

|

|

|

|

Granulator

|

LK-G90

|

|

|

Power

|

90 kW

|

|

|

Chamber Size

|

742*1200 mm

|

|

|

Dimensions

|

2150*2250*2950 mm

|

|

|

Weight

|

5600kg

|

|

|

Hopper Size

|

895*1434*1160 mm

|

|

|

Capacity

|

1500 kg/h

|

|

|

Final Product

|

1~6 mm

|

|

|

Fine Millers

|

|

|

|

Miller

|

LK-M280

|

|

|

Quantity

|

8 Sets

|

|

|

Power

|

30 kW*8

|

|

|

Dimensions

|

2404*1100*1093 mm

|

|

|

Capacity

|

1000-1500 kg/h

|

|

|

Output size

|

30-120 mesh as need

|

|

|

Weight

|

4000 kg

|

|

|

|

|

|

Hot Searches