- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

QISHENG

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

1200x1200x1600mm

-

Marketing Type:

-

Hot Product 2021

-

Weight (KG):

-

750 kg

-

Product Name:

-

concrete hollow blocks machine manual simple brick making machine

-

Transmission Model:

-

Machinery

-

Molding cycle:

-

45s

-

Raw material:

-

Fly Ash Cement Sand Concrete

-

Block Type:

-

Hollow Solid Blocks

-

Block size:

-

400*200*200

-

Forming number:

-

4pcs/mold

-

Capacity:

-

2560pcs/8 hours

Quick Details

-

Type:

-

Hollow Block Making Machine

-

Brick Raw Material:

-

Cement

-

Production Capacity (Pieces/8 hours):

-

2500 pcs/8hours, 1920 pcs/8hours, 1500 pcs/8hours, 12000 pcs/8hours, 2560 pcs/8hours

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

QISHENG

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

1200x1200x1600mm

-

Marketing Type:

-

Hot Product 2021

-

Weight (KG):

-

750 kg

-

Product Name:

-

concrete hollow blocks machine manual simple brick making machine

-

Transmission Model:

-

Machinery

-

Molding cycle:

-

45s

-

Raw material:

-

Fly Ash Cement Sand Concrete

-

Block Type:

-

Hollow Solid Blocks

-

Block size:

-

400*200*200

-

Forming number:

-

4pcs/mold

-

Capacity:

-

2560pcs/8 hours

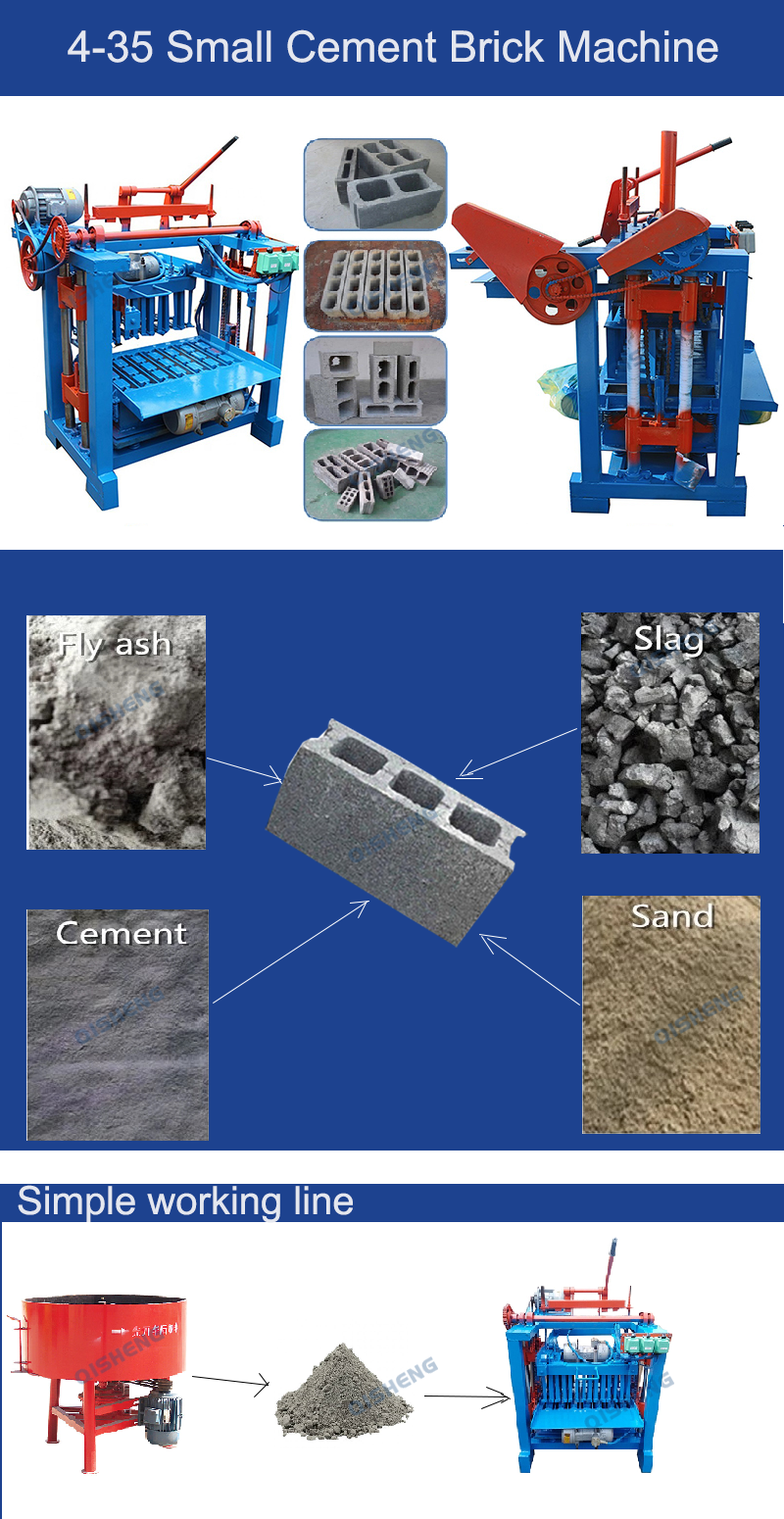

Environmentally friendly QMJ4-35A concrete hollow blocks machine manual simple brick making machine

The material common to many types of natural building are sand , cement, concrete, etc. Natural building tends to rely on human labor, more than technology. QMJ4-35A cement block making machine manually is very affordable for small scale enterprise. In other words, bricks or blocks produced by using this concrete making machine are relatively cheap and affordable for those in the rural areas and for low income earners.

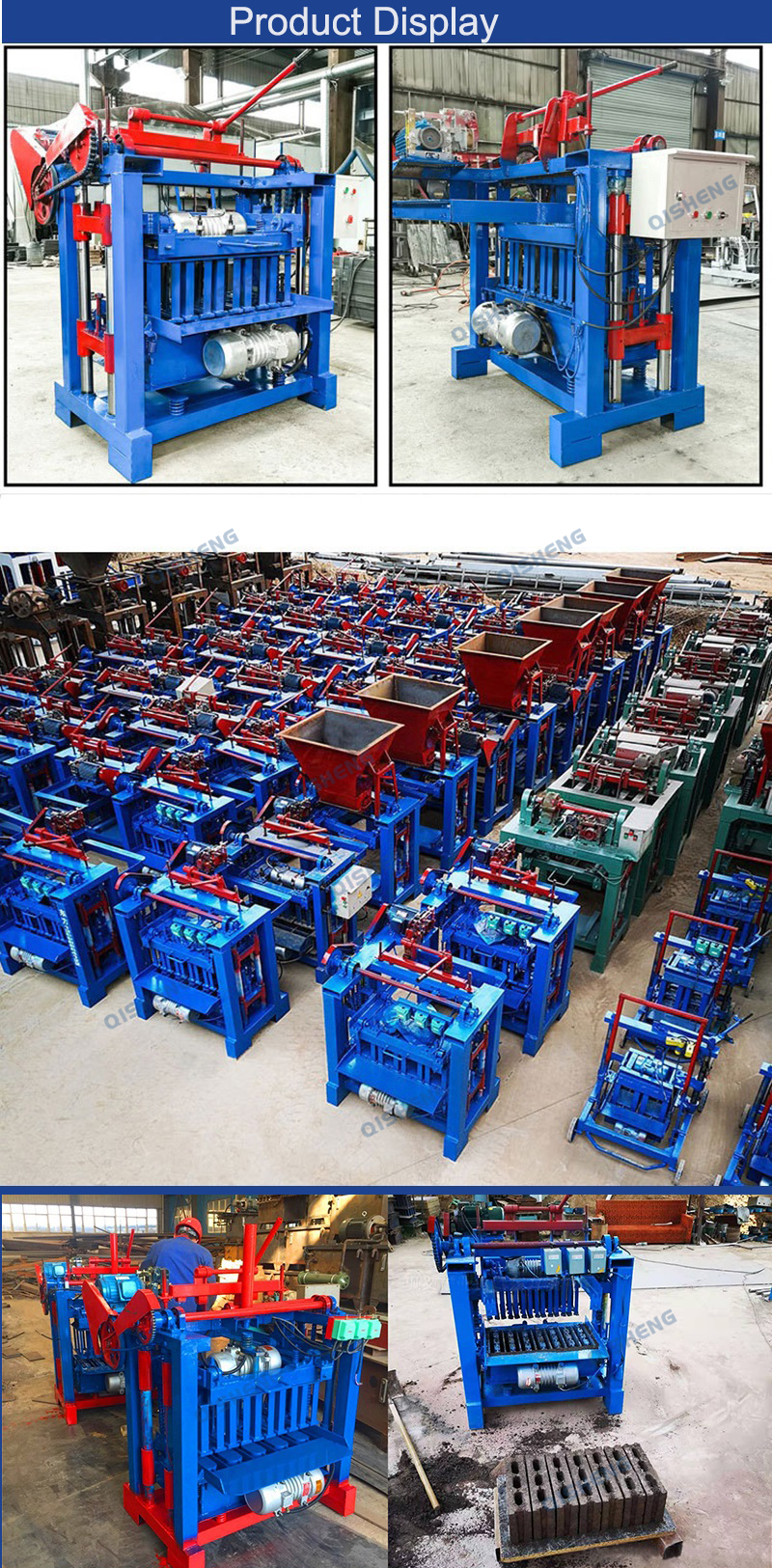

Main Features of small block concrete cement brick making machine:

1) Small investment and high efficiency.

2) No need to hire lot workers.

3) Wide markets in Africa,Fiji,etc.Only you have suitable raw material.

4) the house made by this kind bricks,comfortable,50% money saved.

5) Machine is small, could be transport to any customer's city.

6) High quality bricks for QMJ4-35A machine.

Advantage:

1.Environmentally friendly .Because of using electric,it is very environmental ,not produce the polution air.the used material are slag, construction waste, cement which is using up waste.

2.Operate easily, the machine is convenient for customers to use.

3.Maintenance easily, the brick machine can be cleaned and made some basic maintenance easily by buyers.

4.Saving labor and time, is not only save manpower and time but also improve efficient.

Technical Parameters:

|

45s |

|

|

Machinery |

|

|

Total Weight |

0. 7 5T |

|

Dimensions |

1200x1200x1600mm |

|

Overall Power |

4.8 -5.5 KW |

|

Theoretical capacity of QMJ4-35A low cost brick making machine |

|||

|

Block Size |

Forming Number |

Capacity/8 hours |

|

|

Standard Brick |

240*53*115mm |

4 Block/ mold |

9000-11000 pieces |

|

Hollow Brick |

390*190*190mm |

4 Block/ mold |

|

Raw materials of Cement Brick machine QMJ4-35A:

The raw material it can use is wide such as cement, slag, scree, quicklime,etc.

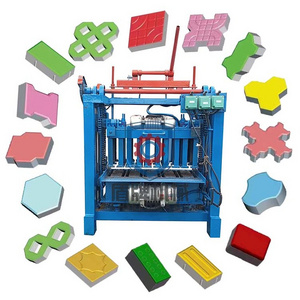

The machine can serve several purposes by exchanging molds. It can produce hollow block, porous block,standard brick, paving block, interlock block and so on.

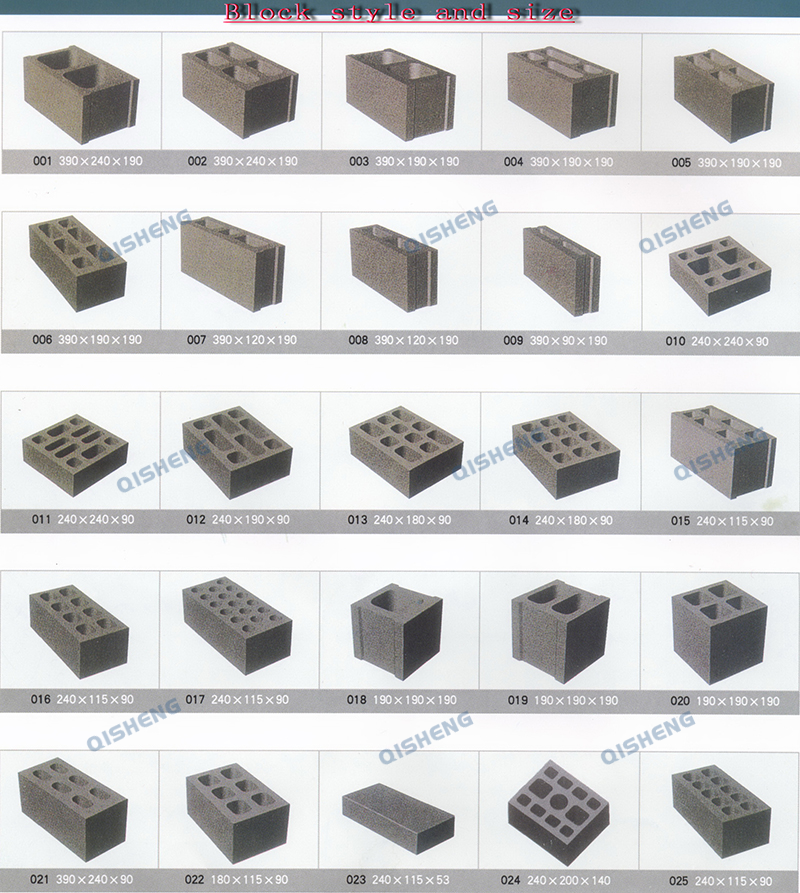

Moulds of concrete hollow brick making machine

:

The failure rate is low, and the operation is simple. Multi-usage, replacement of mold can produce different brick.

Working process of Cement Brick machine QMJ4-35A:

*Firstly,stir the raw material(cement or concrete or fly ash mixture) by concrete mixer,after getting perfect proportion material,by belt conveyor to deliver the raw material into feed bin.

*Secondly,automatically open the door to feed the material,after getting enough ratio material,shut the door of stock bin.

*Finally, press the material and form molding,by press head and mould function,get the bricks shape customer want.

Block samples:

End products:

The replacement of mold can produce different shapes of brick.

Application:

The use of blocks:widely used in housing construction,roads,squares,water conservancy projects,landscape construction.

Detailed Images

1. Reverse-switching: It improves the operability of the automatic clay brick making machine.

2. Vibrating Motor: Domestic famous motor, the advantages of rapid braking, simple structure, high reliability, strong versatility, etc.

3. Mold Box: All frame from the steel by carburizing treatment,enhance the surface hardness and wear resistance,extende the using life.

4. Wearing Part:Low friction bearings are often important for efficiency, to reduce wear and to facilitate high speeds.

Packaging: 1) Standard wooden case packing, nude packing

2) As require your requirements.

Shipping: 1) Professional goods shipping forklift.

2) Port:Qingdao or any port in China

Delivery: within 15-30 days after receiving the payment.

♦Pre-sales:

1 Perfect 7*24hours inquiry and professional consulting service

2.Visit our factory anytime

♦Sale:

1. Update the production schedule in time

2. Quality supervision

3. Product acceptance

4. Shipping on time

♦After-sales:

1. Guarantee:1 year ,during this period we will offer free spare parts if they are broken.

2. Training how to install and use machine

3. Engineers available to service overseas

4. Skill support during the whole using life