- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

JXSC

-

Dimension(L*W*H):

-

depends

-

Weight:

-

3000 KG

-

Product name:

-

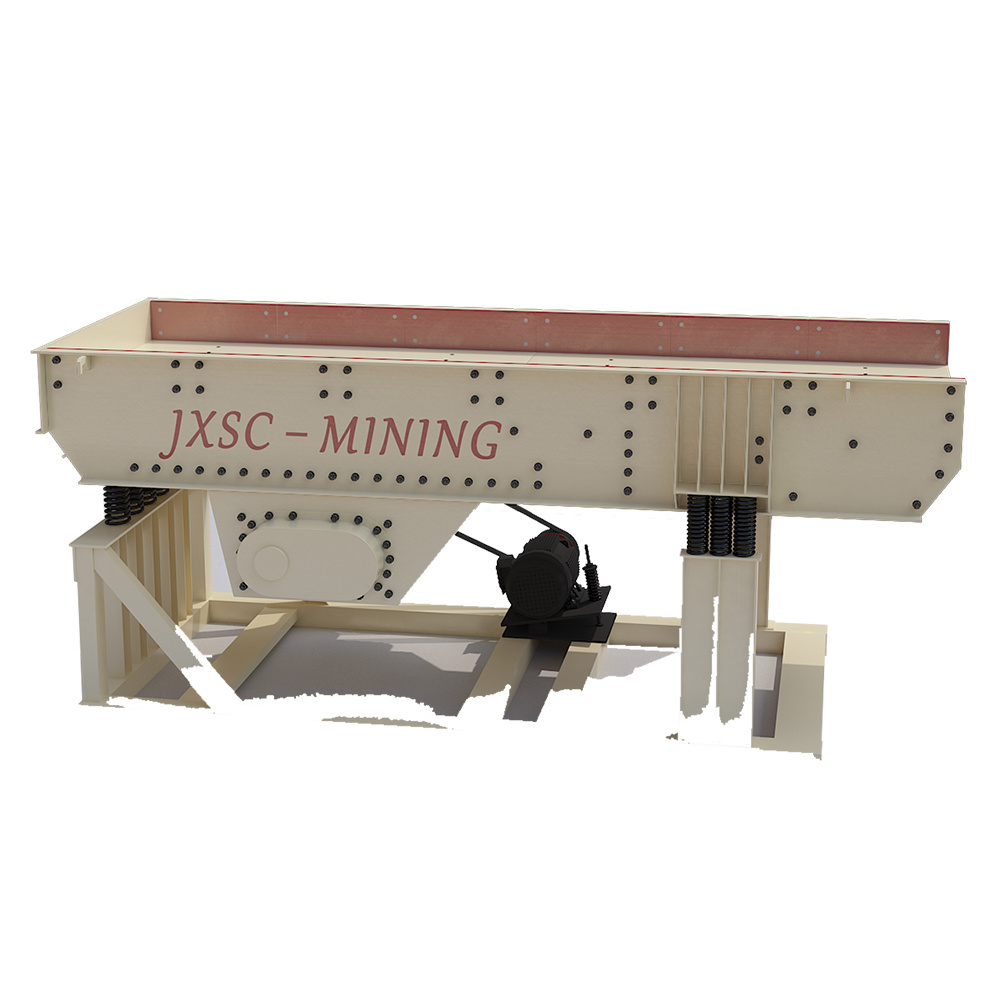

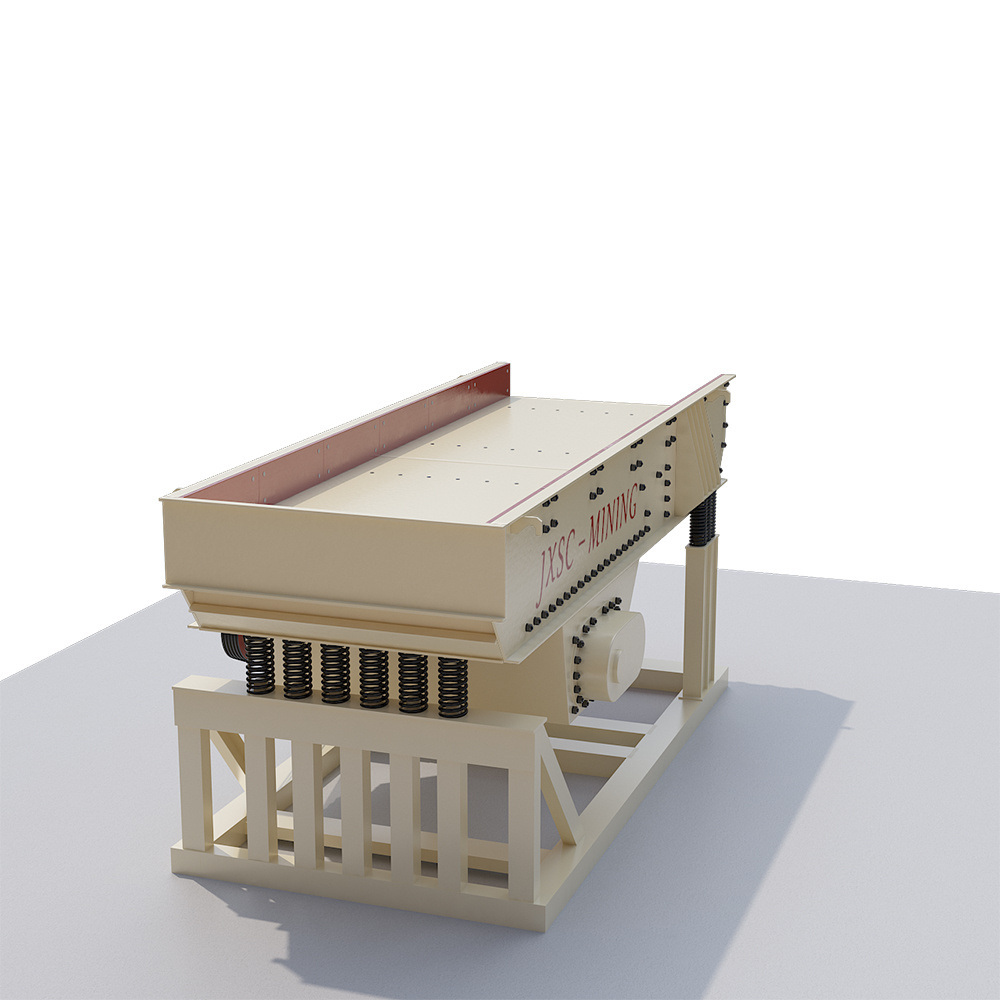

Vibrating Grizzly Feeder

-

Feature:

-

Big Capacity

-

Color:

-

Customers' Requirement

-

Function:

-

Evenly Feeding

-

Usage:

-

Material Feeding

-

Quality:

-

High Level

-

Structure:

-

Simple

-

Price:

-

Negotiable

-

MOQ:

-

1 Set

-

Advantage:

-

High Capacity

Quick Details

-

Marketing Type:

-

Hot Product 2023

-

Application:

-

Mining Construction

-

Capacity(t/h):

-

1-500tph

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

JXSC

-

Dimension(L*W*H):

-

depends

-

Weight:

-

3000 KG

-

Product name:

-

Vibrating Grizzly Feeder

-

Feature:

-

Big Capacity

-

Color:

-

Customers' Requirement

-

Function:

-

Evenly Feeding

-

Usage:

-

Material Feeding

-

Quality:

-

High Level

-

Structure:

-

Simple

-

Price:

-

Negotiable

-

MOQ:

-

1 Set

-

Advantage:

-

High Capacity

Product Description

Product Introduction

Structure

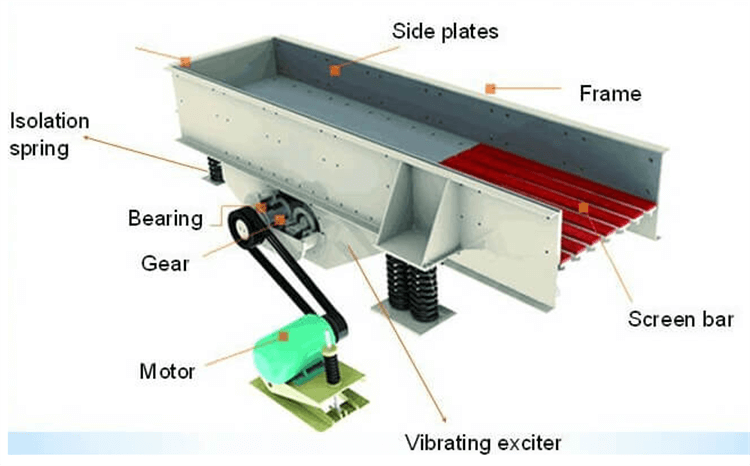

1. Feed Tank

The feed tank(material trough) is a load-bearing component, which is used to bear the stored materials and deliver them to the next receiving equipment by vibration. According to the actual needs, the material trough is made of carbon steel plate, low alloy structural steel plate, heat-resistant steel plate or aluminum alloy plate.

2. Vibration Exciter

vibration exciter is composed of two eccentric shafts (active and passive) and gear.Commonly used exciters are inertial exciters, elastic link exciters, electromagnetic exciters, hydraulic or pneumatic exciters, and cam exciters.

3. Spring Support

The support spring mainly supports the vibrating machine body, so that the machine body realizes the required vibration and reduces the dynamic load

transmitted to the foundation or frame.

transmitted to the foundation or frame.

4. Transmission Device

Vibration motor drives the exciter to generate exciting force for work.

Product display

Technical data

According the installation of vibration feeder, it can be divided into down vibration type and side vibration type. The hanging type is the most common one, and it also has the requirement of seat type design. According to the layout requirements of feeder users, it can be designed into sealed type and open type. The import and export styles can be customized according to the requirements. Accord the structure and application, vibrating feeder also can be divided into GZD, ZSW and GZZ serial.

|

Model

|

Funnel Size

(mm×mm) |

Input size (mm)

|

Capacity (t/h)

|

Motor Power

(kw) |

Weight (kg)

|

Dimensions(mm)

|

|

GZD-800×3000

|

800×3000

|

400

|

80-120

|

2.2

|

3195

|

3110×1800×1600

|

|

GZD-960×3800

|

960×3800

|

500

|

120-210

|

2.2×2

|

3375

|

3850×1950×1630

|

|

GZD-1100×4200

|

1100×4200

|

580

|

200-430

|

3.7×2

|

4400

|

4400×2050×1660

|

|

GZD-1100×4900

|

1100×4900

|

580

|

280-500

|

5.5×2

|

4675

|

5200×2050×1700

|

|

GZD-1300×5200

|

1300×5200

|

650

|

450-600

|

7.5×2

|

5400

|

5200×2350×1750

|

|

ZSW-950×3800

|

950×3800

|

500

|

96-160

|

11

|

4100

|

3882×2224×2121

|

|

ZSW-1100×4200

|

1100×4200

|

580

|

120-240

|

15

|

4745

|

4310×2500×1365

|

|

ZSW-1100×4900

|

1100×4900

|

580

|

120-280

|

15

|

5420

|

4957×2500×1365

|

|

ZSW-1100×5900

|

1100×5900

|

630

|

160-350

|

22

|

6100

|

6000×2500×2150

|

|

ZSW-1300×5900

|

1300×5900

|

630

|

250-400

|

37

|

6300

|

6000×2700×2150

|

More Model Please Contact Us,the Model Also Can Be Customized!

Advantages and Features

Working Principle

2. Easy installation and maintenance, low operating cost.

3. High efficiency and high feeding capacity.

4. Low noise is conducive to improving the working environment.

5. The feeding material is uniform, the continuous performance is good, and the excitation force is adjustable.

6. Change and control flow at any time, easy to operate. Adjusting eccentric block can adjust the feed quantity conveniently.

7. Eccentric block is excitation source, low noise, less power consumption, good regulation performance, no blanking phenomenon.

8. If the enclosed fuselage is used, dust pollution can be prevented.

9. It has stable vibration, reliable operation and long life, and has strong adaptability to various materials.Flexibility in design options ensures a seamless fit into your existing production processes for your specific

application.

application.

10. The grid gap is adjustable.

11. There are more wear parts.

12. Special grille design can prevent material from clogging.

We have Trough Feeder, Swing Feeder, Plate feeder, Disk feeder and so on. Welcome to consult!

Successful Cases

Packaging & Delivery

●Ways Of Packing

● Shiping by sea/air freight

|

1.Small parts packed in the wooden cases.

|

or any way the customer requires.

|

|

2.Big parts packed by plastic membrane.

|

|

|

3.The whole big machine is loaded in the container.

|

|

Company Introduction

JXSC Mining Equipment Manufacturer is an experienced supplier of Gold Mining Equipment including gold wash plant, stone crusher machine, gravity concentration, magnetic separation, feeder equipment, mining laboratory equipment. Our Gold Wash Plant is widely used for gold mining plant among home and abroad, whole alluvial gold production line and gold mining equipment, diamond mining equipment, silica sand mining own a good name in the international market, owing to advanced design compare to top brands like MSI MINING.

Trusted mining equipment manufacturers leader in mineral processing technologies,ISO9001: 2008 and CE certified,providing high quality manufacturing,engineering support & professional mining design since establishing in China in 1985.

JXSC mine machinery factory, is specializing in manufacturing, and uniquely provides complete range of mining equipment, mining accessories for either placer or hard rock mineral types,also,processing and recovery of various metals and minerals: Precious Metals, Precious and Semi-Precious Stones, Base Metals, Ferrous and Non-Ferrous Metals, Noble Metals, Heavy Metals.

7*24 hours online consulting service, we provide you with the prophase plan, process flow design and

manufacturer equipment according to your special demand.

Send technicians to the job site guiding the installation and adjustment, training operators and finishing the check and accept together with you.

FAQ

1.How is the quality of your products?(mining equipment/machine)

Answer: Our products are manufactured strictly according to national and international standard, and we will do a test on every machine before delivery.

2.Guaranteed?

Answer: All of our

products are guaranteed for one year. If products quality is not consistent with the description or promise we made before you place order, we promise 100% refund.

3.How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

4.Service and Payment Terms?

Answer: We can accept T/T and L/C; 30% deposit, 70% balance before factory delivery, which is international trade practice; Finished product pictures will be provided to customers before delivery.

If you are interested in our products, please don't hesitate to contact us. Could you tell me the following questions, so that I can give you a complete solution, including best Exw-works Price Quotation!

1. Which machine do you need? like gold washing machine, spiral chute, vibrating screen, Jig separator, Shaking table, etc.

2. What is your raw ore that you plan to process? like gold ore, diamond ore, tantalite or silica sand, etc.

3. What is the capacity you need? Like 10 tones per hour.

4. What is the feeding size to the machine? and what is the discharging-material size that you require? Sincerely welcome to send your inquiry,you can get best quotation and professional service.

Hot Searches