- Product Details

- {{item.text}}

Quick Details

-

Power:

-

37kw

-

Dimension(L*W*H):

-

Depend on the model

-

Weight:

-

70.7t

-

Warranty:

-

One Year

-

Name:

-

Mini lime cement making machinery rotary kiln for cement

-

Keyword:

-

mini lime cement rotary kiln

-

Material:

-

Carbon Steel

-

Sealing type:

-

Kiln Hood

-

Application:

-

Limestone,Ore or other

-

Model:

-

YZ1939

-

Cylinder diameter:

-

1900mm

-

Cylinder length:

-

39000mm

-

Capacity:

-

1.6-3.4tph

-

Certification:

-

ISO9001:2008 and CE

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

XKJ

-

Voltage:

-

220v/380v

-

Power:

-

37kw

-

Dimension(L*W*H):

-

Depend on the model

-

Weight:

-

70.7t

-

Warranty:

-

One Year

-

Name:

-

Mini lime cement making machinery rotary kiln for cement

-

Keyword:

-

mini lime cement rotary kiln

-

Material:

-

Carbon Steel

-

Sealing type:

-

Kiln Hood

-

Application:

-

Limestone,Ore or other

-

Model:

-

YZ1939

-

Cylinder diameter:

-

1900mm

-

Cylinder length:

-

39000mm

-

Capacity:

-

1.6-3.4tph

-

Certification:

-

ISO9001:2008 and CE

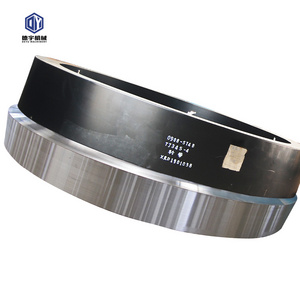

Rotary kiln is also known as rotation kiln. There are many kinds of rotary kiln produced by our company,according to applicable industries, it is divided into metallurgical rotary kiln and chemical rotary kiln; According to the applicable materials, it can be divided into cement rotary kiln, lime kiln, ceramic sand rotary kiln, metal magnesium rotary kiln, bauxite kiln etc.The rotary kiln is composed of barrel, supporting device, catch wheel supporting device, transmission device, movable kiln head, kiln tail sealing device, and coal injection pipe device.

|

Product Specification (m) |

Kiln dimensions |

Motor power (kw) |

Total weight (t) |

note | ||||

|

Diameter (m) |

Length (m) |

Obliquity (%) |

Capacity (t/d) |

Rotation speed (r/min) |

||||

| Φ2.5×40 | 2.5 | 40 | 3.5 | 180 | 0.44-2.44 | 55 | 149.61 | ----- |

| Φ2.5×50 | 2.5 | 50 | 3 | 200 | 0.62-1.86 | 55 | 187.37 | ----- |

| Φ2.5×54 | 2.5 | 54 | 3.5 | 280 | 0.48-1.45 | 55 | 196.29 | outside disassemble kiln |

| Φ2.7×42 | 2.7 | 42 | 3.5 | 320 | 0.10-1.52 | 55 | 198.5 | ------ |

| Φ2.8×44 | 2.8 | 44 | 3.5 | 450 | 0.437-2.18 | 55 | 201.58 | outside disassemble kiln |

| Φ3.0×45 | 3 | 45 | 3.5 | 500 | 0.5-2.47 | 75 | 210.94 | ------ |

| Φ3.0×48 | 3 | 48 | 3.5 | 700 | 0.6-3.48 | 100 | 237 | outside disassemble klin |

| Φ3.0×60 | 3 | 60 | 3 | 800 | 0.3-2 | 100 | 310 | ------ |

| Φ3.2×50 | 3.5 | 50 | 4 | 1000 | 0.6-3 | 125 | 278 | disassemble klin |

| Φ3.3×52 | 3.3 | 52 | 3.5 | 1300 | 0.266-2.66 | 125 | 283 | kiln with preheater precalcine |

| Φ3.5×54 | 3.5 | 54 | 3.5 | 1500 | 0.55-3.4 | 220 | 363 | kiln with prehrater precalcine |

| Φ3.6×70 | 3.6 | 70 | 3.5 | 1800 | 0.25-1.25 | 125 | 419 | Generating klin for usimg ofterheat |

| Φ4.0×56 | 4 | 56 | 4 | 2300 | 0.41-4.07 | 315 | 456 | klin with prehrater precalcine |

| Φ4.0×60 | 4 | 60 | 3.5 | 2500 | 0.396-3.96 | 315 | 510 | klin with prehrater precalcine |

| Φ4.2×60 | 4.2 | 60 | 4 | 2750 | 0.41-4.07 | 375 | 633 | klin with prehrater precalcine |

| Φ4.3×60 | 4.3 | 60 | 3.5 | 3200 | 0.396-3.96 | 375 | 583 | klin with prehrater precalcine |

| Φ4.5×66 | 4.5 | 66 | 3.5 | 4000 | 0.41-4.1 | 560 | 710.4 | klin with prehrater precalcine |

| Φ4.7×74 | 4.7 | 74 | 4 | 4500 | 0.35-4 | 630 | 849 | klin with prehrater precalcine |

| Φ4.8×74 | 4.8 | 74 | 4 | 5000 | 0.396-3.96 | 630 | 899 | klin with prehrater precalcine |

| Φ5.0×74 | 5 | 74 | 4 | 6000 | 0.35-4 | 710 | 944 | klin with prehrater precalcine |

| Φ5.6×87 | 5.6 | 87 | 4 | 8000 | Max4.23 | 800 | 1265 | klin with prehrater precalcine |

| Φ6.0×95 | 6 | 95 | 4 | 10000 | Max5 | 950×2 | 1659 | klin with prehrater precalcine |

|

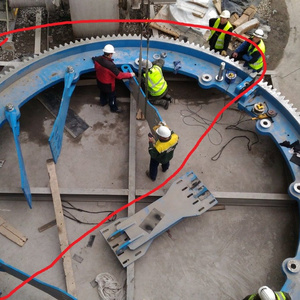

ROTARY KILN CASE

Capacity: 12.5TPH

|

|

|

ROTARY KILN CASE

Capacity: 10TPH

|

Rotary kiln cylinder composed of steel plate, cylinder body with build by laying bricks or stones of refractory lining, and horizontal line into slope, three belting leather in each block supporting device, in the material near the end belting leather across the inner cylinder with tangential spring plate fixed on a big gear ring, which is a small gear meshing.During normal operation, the main drive motor is transmitted to the open-type gear device by the main drive motor, which drives the rotary kiln.Materials are calcined from the end of the kiln.Due to the effect of tilting and slow rotation of the cylinder, the material is along the circumference of a circle and tumbling along the axial direction (from high to low) mobile, continue to complete the process, and generate the clinker kiln hood into the cooling machine cooling.The fuel is sprayed into the kiln by the kiln head, and the waste gas and materials produced in the furnace are exchanged for impact crusher, which is exported by the kiln tail.This design does not contain fuel burner.

Henan Xingkuang Machinery Co., Ltd., is a large sized joint-stock enterprise integrated with the scientific research,production and sales of heavy mining machinery. The company have five standard heavy industrial workshops covering 80,000 square meters,more than 160 machines used for gold processing,plug welding and assembling with large and medium sizes, and more than 500 works including over 50 administrators with intermediate and senior title and engineering technicians.

Q Are you a trading company or a manufacturer?

A we are the factory.

Q Product quality assurance?

A

Henan Xingyang Mining Machinery Manufactory provides our customers with a 12-month warranty on the delivery date of the machines we export.

During the warranty period, if any material or workmanship defects occur during normal operation, we will replace or repair defective parts at our own discretion.

Q what information should the customer give us so that we can provide the appropriate quotation and service?

A

What material are you dealing with?

What are the requirements for the final product?

How much production does your project need per hour?

The rotary kiln temperature you want to reach

The raw material max feeding size?

Q How long is your equipment warranty? Does your company supply spare parts?

A the warranty period of the rotary kiln is one year. We will provide spare parts for you at the lowest price.In the warranty period, if any material or workmanship defects occur during normal operation, we will replace or repair defective parts as appropriate.

Q If I need a full production line, can you help us design and build it?

A Yes, we can help you design a complete production line and give you relevant professional advice. We have established many projects in China and overseas.

Q Can we visit your factory?

A Yes. You can visit our factory anytime you want.