- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ZZCHRYSO

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

320mm*230mm*210mm

-

Motor Power (Kw):

-

180KW/220KW

-

Weight (KG):

-

13900 KG

-

Marketing Type:

-

New Product 2024

-

Product name:

-

Biomass Wood Pellet Making Machine

-

Ring mold size(mm):

-

768

-

Press roller quantity(pcs):

-

2

-

Transmission method:

-

Water-cooled synchronous motor Timing belt + gear

-

Feeding type:

-

Horizontal screw + forced feeding

-

Application:

-

Make Biomass Pellets

-

Raw material:

-

Sawdust\straw\rice Husk\wood Waste

-

Capacity:

-

2.5-4.5(t/h)

Quick Details

-

Pellet Diameter (mm):

-

4 - 12

-

Output (kg/h):

-

2500 - 4500 kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZZCHRYSO

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

320mm*230mm*210mm

-

Motor Power (Kw):

-

180KW/220KW

-

Weight (KG):

-

13900 KG

-

Marketing Type:

-

New Product 2024

-

Product name:

-

Biomass Wood Pellet Making Machine

-

Ring mold size(mm):

-

768

-

Press roller quantity(pcs):

-

2

-

Transmission method:

-

Water-cooled synchronous motor Timing belt + gear

-

Feeding type:

-

Horizontal screw + forced feeding

-

Application:

-

Make Biomass Pellets

-

Raw material:

-

Sawdust\straw\rice Husk\wood Waste

-

Capacity:

-

2.5-4.5(t/h)

Product Description

Wood pellet machine turns wooden materials, such as timber, bark, chip, cornstalk, sawdust, etc., into pellets. The biomass pellet maker turns the raw material into cylindrical pellets by putting pressure and heat.

Wood pellet machine turns the raw materials into the high-efficient biomass fuel. What’s more, the conversion of raw material into more energy-dense forms facilitates transport, storage and use through the rest of the value chain. The future of the biomass ison continuous developing. The biomass fuel would like to replace the traditional fuel gradually.

Raw Material

Various raw materials can be processed into biomass pellets, including wood and wood waste, agricultural residues such as straw and corn stover, energy crops like switchgrass and miscanthus, and organic industrial and urban waste. These materials are typically processed into pellets through methods such as drying, crushing, and pelletizing to create a dense and uniform fuel source for heating and electricity generation.

Feature

1.

Energy-saving:

By utilizing rotational kinetic energy and increasing the effective lever arm, the machine can achieve a production rate of 4.5-5 tons per hour while saving over 45% of energy .

2. Stability: The main machine weighs 14 tons and is made of integral alloy forged parts. The synchronous motor, along with the enlarged synchronous wheel, provides a large torque and rotational inertia, ensuring stable operation without blockages .

3. Strong adaptability: The machine is capable of compressing different materials and even materials with high moisture content .

4. Low maintenance cost: The roller only requires oiling once every 500 hours of operation, resulting in low maintenance expenses.

5. Extended warranty: The chassis, main shaft, hollow shaft, gears, and synchronous motor are all covered by a two-year warranty,providing customers with an extended period of quality assurance .

2. Stability: The main machine weighs 14 tons and is made of integral alloy forged parts. The synchronous motor, along with the enlarged synchronous wheel, provides a large torque and rotational inertia, ensuring stable operation without blockages .

3. Strong adaptability: The machine is capable of compressing different materials and even materials with high moisture content .

4. Low maintenance cost: The roller only requires oiling once every 500 hours of operation, resulting in low maintenance expenses.

5. Extended warranty: The chassis, main shaft, hollow shaft, gears, and synchronous motor are all covered by a two-year warranty,providing customers with an extended period of quality assurance .

Specification

|

Model

|

CRS608

|

CRS788

|

|

|

Capacity(t/h)

|

2.5-3

|

4-4.5

|

|

|

Motor power(kw)

|

180(90*2)

|

220(110*2)

|

|

|

Ring mold size(mm)

|

∅608

|

∅768

|

|

|

Press roller quantity(pcs)

|

2

|

|

|

|

Transmission method

|

Asynchronous motor

V-belt + gear |

Water-cooled synchronous motor

Timing belt + gear |

|

|

Feeding type

|

Horizontal screw + forced feeding

|

|

|

|

Machine size(m)

|

3.2*2.2*2.1

|

3.2*2.3*2.1

|

|

|

Weight(kgs)

|

8480

|

13900

|

|

Product Display

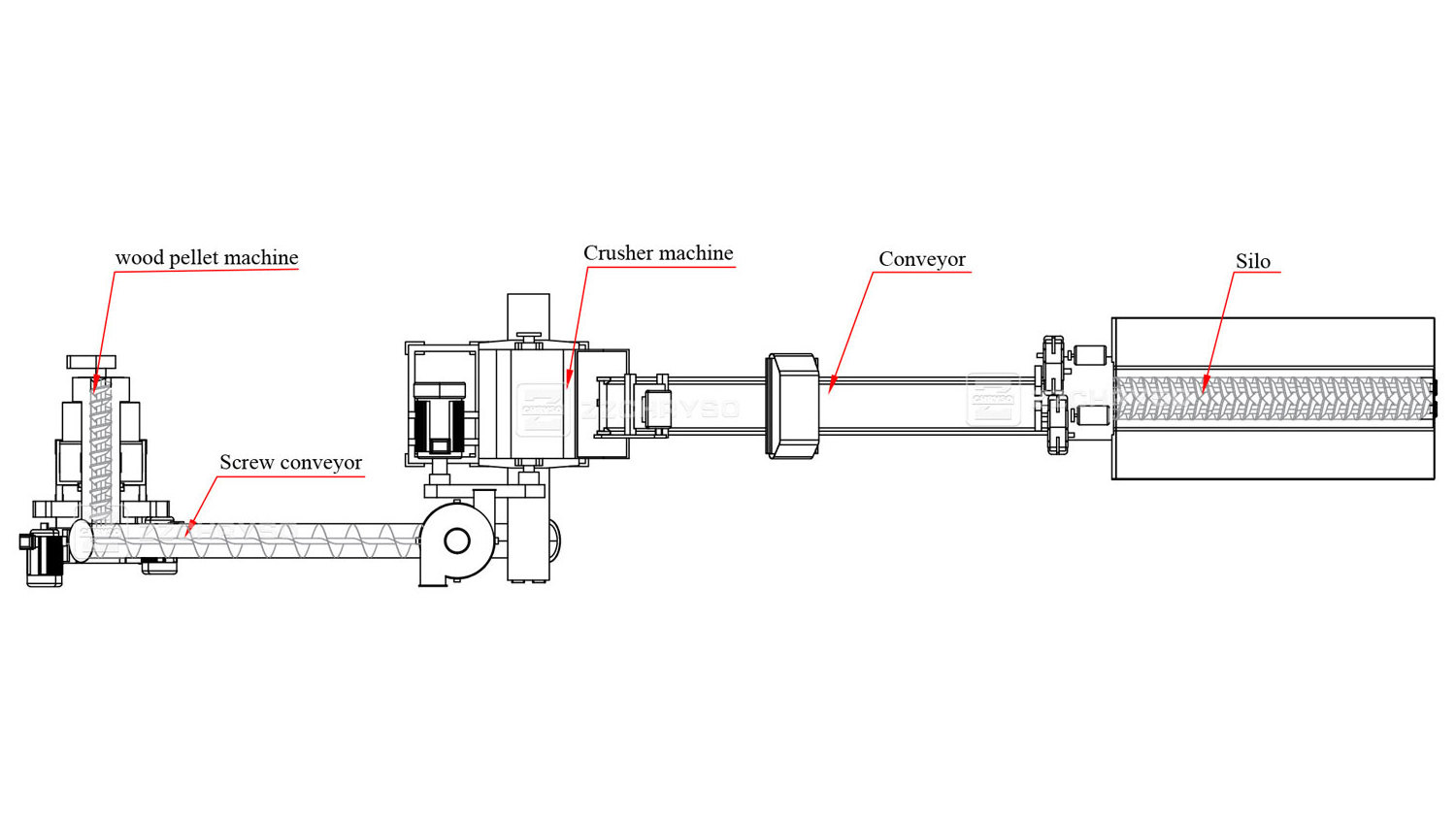

Whole Production Line

A complete wood pellet production line includes crushing, drying, pelletizing, and packaging units.

1. Crushing : Wood blocks, wood chips, or other wood materials are uniformly crushed. This can be done using a wood crusher or shredder to reduce the size of the wood into smaller pieces.

2. Drying : The crushed wood material is then fed into a drying machine drum through a conveyor belt. The drying process quickly reduces the moisture content of the material to around 12% to 15%. This is important for ensuring the quality of the final wood pellets.

3. Pelletizing : Once the wood material is dried, it is then fed into a pellet mill. The pellet mill compresses the material under high pressure and heat, forming it into small cylindrical pellets. The pellets are then extruded from the pellet mill.

4. Packaging : The pellets are discharged from the pellet mill and can be directly connected to a conveyor belt that leads to an packaging machine. The packaging machine packages the pellets into bags

1. Crushing : Wood blocks, wood chips, or other wood materials are uniformly crushed. This can be done using a wood crusher or shredder to reduce the size of the wood into smaller pieces.

2. Drying : The crushed wood material is then fed into a drying machine drum through a conveyor belt. The drying process quickly reduces the moisture content of the material to around 12% to 15%. This is important for ensuring the quality of the final wood pellets.

3. Pelletizing : Once the wood material is dried, it is then fed into a pellet mill. The pellet mill compresses the material under high pressure and heat, forming it into small cylindrical pellets. The pellets are then extruded from the pellet mill.

4. Packaging : The pellets are discharged from the pellet mill and can be directly connected to a conveyor belt that leads to an packaging machine. The packaging machine packages the pellets into bags

Related Products

Comprehensive Wood Chipper

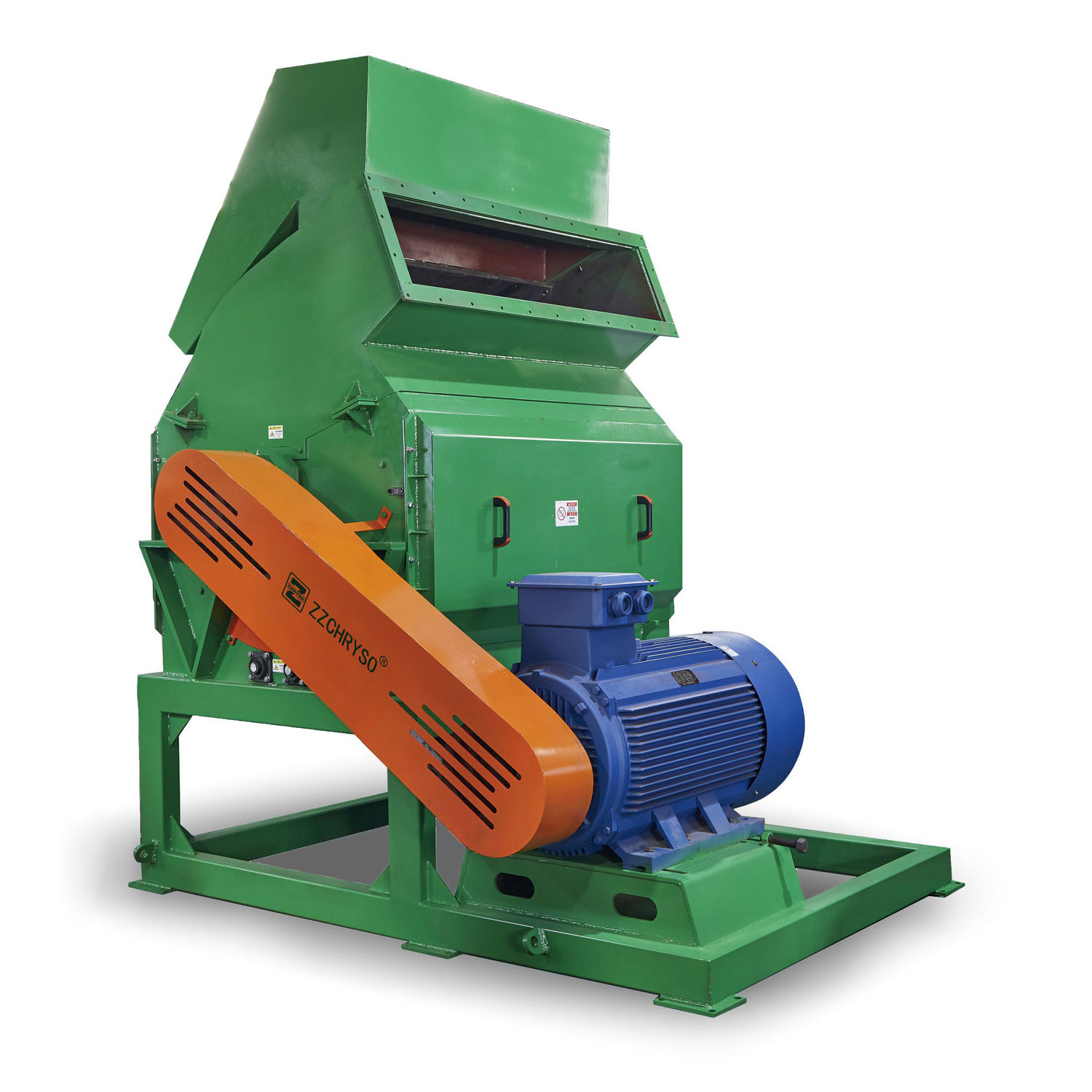

Wood Crusher

Hot Searches