KINGREAL is equipped with a team of professional engineers for customised design.

Conventional thickness: 1.0mm, 1.5mm, 2.0mm, etc.

Common specifications:Large sheets, 1200*2400, 8500*2400, etc., sizes can be customised.

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KINGREAL

-

Voltage:

-

380V

-

Weight:

-

15000 kg

-

Product name:

-

Hook-on Roll Forming Machine

-

Usage:

-

Metal ceiling production

-

Raw material:

-

Gi Steel, Aluminum

-

Thickness:

-

0.3-1.0mm

-

Roller material:

-

Cr12 Steel quenched

-

Control system:

-

Touch screen

-

Cutting blade material:

-

CR12MOV

-

PLC:

-

Fatek

-

Main motor power:

-

10KW

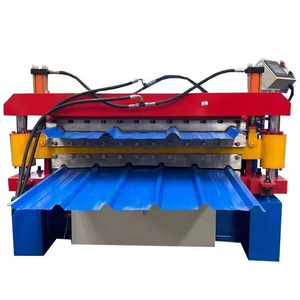

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

Other

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KINGREAL

-

Voltage:

-

380V

-

Weight:

-

15000 kg

-

Product name:

-

Hook-on Roll Forming Machine

-

Usage:

-

Metal ceiling production

-

Raw material:

-

Gi Steel, Aluminum

-

Thickness:

-

0.3-1.0mm

-

Roller material:

-

Cr12 Steel quenched

-

Control system:

-

Touch screen

-

Cutting blade material:

-

CR12MOV

-

PLC:

-

Fatek

-

Main motor power:

-

10KW

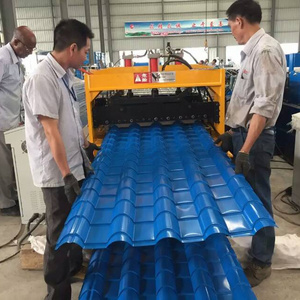

Products Description

Hook-on Roll Forming Machine

Hook-on Roll Forming Machine is mainly composed of uncoiler, leveller, punch press, roll forming machine, electric control system, hydraulic system, fixed length shear station and other components.

PLC control system is adopted to achieve production automation; it can be adjusted by inputting parameters such as product length and production quantity in the touch screen; continuous production without stopping ensures stable product quality and accurate size.

Feature

1.PLC control width and size change, fully automatic, non-human manual operation, reduce a lot of errors, save a lot of testing costs.

2.Pre-cutting system, can cut any length of the panel.

3. Full series of famous brand electrical appliances such as Yaskawa, Snyder, Shihlin, etc., the service life is greatly extended and the use is guaranteed.

Equipped with oil-cooled fan to achieve heat dissipation.

4.KINGREAL has installed a lot of this equipment all over the world, USG, Jawdah and other famous manufacturers are using our equipment.

Main Components

Hydraulic Decoiler

In addition, KINGREAL offers a wide range of decoilers to choose from.

Rollers are chrome plated for durability and long life; No damage to the surface of the material, suitable for all kinds of metal

sheets.

sheets.

Through the touch screen, the width can be adjusted automatically with a high degree of accuracy, with an error range of ±0.1mm, avoiding a lot of waste and error caused by hand cranking.

High precision, good molding effect

Selected high-quality plaque, the force strength is large.

Reference Date

|

Raw Material

|

Galvanized steel or Al strip.

Acocording to the customers need.

|

|

Spring tee sizes

|

According with customers’ drawing

|

|

Maximum forming speed

|

30m/min

|

|

Roll Forming stands

|

15-20 Rollers station

|

|

Usage

|

Shelves & Racks

|

|

Machine Power

|

~ 35 KW

|

Working Process

The Hook-on

roll forming machine

working peocess

Raw Material Hydraulic Decoiler→Straightener Machine→Main Roll Forming Machine→ Shearing Station→Product Output.

Related products

Application

Hooked ceiling is a kind of aluminium ceiling products, hooked aluminium ceiling is a unified hooked structure, most of the unified panel size, unified keel installation, easy to adjust the level, save installation time, save labour costs, while having the advantages of standard and non-standard panels. Hook-and-loop board is a kind of aluminium ceiling ceiling specially designed for large-scale large area of the same space, its characteristics are: simple and generous, unified, neat, flat, clear lines, easy to install, shading, windproof and so on.

Hot Searches