- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Sunward for pasta straw production line

-

Voltage:

-

customizable for pasta straw production line

-

Power:

-

customizable for pasta straw production line

-

Dimension(L*W*H):

-

3100*900*2000mm

-

Weight:

-

1500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product Name:

-

pasta straw production line

-

Electric parts:

-

CHINT

-

Inverter:

-

Delta inverter

-

Relay:

-

Omron relay

-

Main material:

-

stainless steel

-

color:

-

silver,or as clinets requirment

-

Application:

-

pasta straw line

-

Advantage:

-

Low Noise High Production

-

Raw material:

-

Whear Flour

Quick Details

-

Production Capacity:

-

99.9%

-

Type:

-

pasta

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Sunward for pasta straw production line

-

Voltage:

-

customizable for pasta straw production line

-

Power:

-

customizable for pasta straw production line

-

Dimension(L*W*H):

-

3100*900*2000mm

-

Weight:

-

1500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product Name:

-

pasta straw production line

-

Electric parts:

-

CHINT

-

Inverter:

-

Delta inverter

-

Relay:

-

Omron relay

-

Main material:

-

stainless steel

-

color:

-

silver,or as clinets requirment

-

Application:

-

pasta straw line

-

Advantage:

-

Low Noise High Production

-

Raw material:

-

Whear Flour

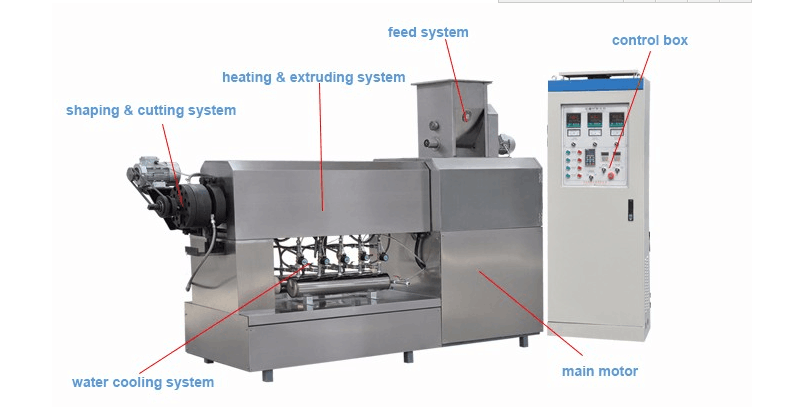

3D Indian Pellet Snacks Pani Puri Golgappa Fryums Extruder Making Machine

Pasta straw production line Introduction

pasta straw production line is used for making biodegradable dinking straws. This straw is a new product, which is eco-friendly. Its degradation time is much shorter than traditional plastic straws. This line is made up with raw materials treatment machines, single screw or twin-screw extruder, cooling conveyer and cutting machine

1.Extruder details of the pasta straw production line :

EXT100 for pasta straw production line

2. Capacity of the pasta straw production line :

100-120kg/h or could customizalbe.

3. pasta straw production line materials:

Structure: 45#steel

Screws: 38CrMnAl,

Cover board:stainless steel

All parts where touch product are food grade stainless steel.

4.P asta straw production line Features:

(1) High work efficiency, automation degree.

(2) Low land occupation, power consumption, labor cost, waste rate.

(3) Various configurations and capacity choices.

(4) Various finished products sizes.

(5) Production factors can be quantified and controlled.

(6) World-class food grade fittings.

(7) All machines and fittings can be custom-made. ODM or OEM is available.

(8) Professional pre-sale, sale and after-sale service.

(9) Equipped with inverters to control speed.

5.The pasta straw production line has self-cleaning function.

6 . Flow chart of the pasta straw production line:

Mixing system---Extrusion system----Cutting system---Drying system

6 . Voltage of pasta straw production line in China : Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers’ Local voltage according to different countries.

7. Technical parameter of pasta straw production line

|

Model parameter |

Mixer |

EXT100 Extruder |

Cooling machine |

Dryer |

Fryer |

Hoister |

Roller |

|

Installed capacity |

4kw |

47kw |

1kw |

30kw |

45kw |

1.1kw |

0.37kw |

|

Real power |

3kw |

26kw |

0.6kw |

20kw |

30kw |

1kw |

0.3kw |

|

output |

260kg/h |

120kg/h |

120kg/h |

120kg/h |

120kg/h |

150kg/h |

150kg/h |

8.Why Invest pasta straw production line Business?

Billions of plastic products are used every day. They are convenient and low-cost. But the pollution cased by them is more obvious. Most plastic products need several decades to be degraded which is even longer than human longevity. This problem seriously influences on country economy, people's lives and environmental protection. Thanks to science and technology development, this problem is alleviated greatly by biodegradable products made from food or other materials.

pasta straw production line is one kind of products, which is made from rice powder and tapioca powder. Its core production technique is modern extrusion technology. Because the raw materials are food, this straw is safe and pollution-free. This drinking straw will be decomposed within 100 days after using. Consumers can even eat it, which has a little rice flavor.

The detail of the pasta straw production line

Packaging and loading of pasta straw production line

Pre-sale service for

pasta straw production line

1.Related machines’s technical parameter will be supplied to customer.

2.According to customer’s factory size, factory layout can be provided in advance.

3. According to customer’s material cost, general formulation can be prepared well.

4.Special machine can be supplied as customer’s request.

5.Professional Advice about Market, machines, processing , materials, packing can be supplied

6. Suggesting professional ship agent or helping book ship as customer request.

After sale service for pasta straw production line

1.Allocation chart as the buyer’s request will be supplied.

2.Operation manual will be supplied after shipment.

3.One year warrantee, life time maintenance with cost price.

4.Free easy broken spare parts will be sent with container .

5.First installation can be done by engineer.

6.Training workers in customer’s factory.