- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

Jianha

-

Year:

-

2023

-

Voltage:

-

220V/ 380V or Customized

-

Dimension(L*W*H):

-

1690*1200*3376

-

Weight (T):

-

13.5 T

-

Model Number:

-

315TC-F

-

Motor Power (kw):

-

18.5 kw

-

Marketing Type:

-

New Product 2023

Quick Details

-

Machine Type:

-

Four-column Three-beam Hydraulic Press

-

Slide Stroke (mm):

-

800

-

Return Force (kN):

-

300 kN

-

Place of Origin:

-

China

-

Brand Name:

-

Jianha

-

Year:

-

2023

-

Voltage:

-

220V/ 380V or Customized

-

Dimension(L*W*H):

-

1690*1200*3376

-

Weight (T):

-

13.5 T

-

Model Number:

-

315TC-F

-

Motor Power (kw):

-

18.5 kw

-

Marketing Type:

-

New Product 2023

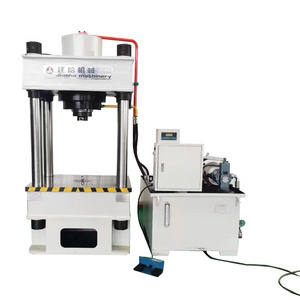

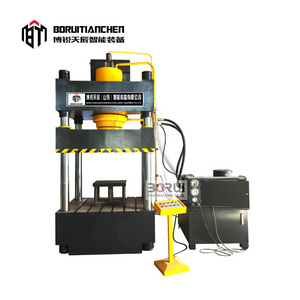

Specification

The 315 ton industrial four column hydraulic press machine manufacture structure is formed, and various parameters and table tops can be customized according to customer needs. The hydraulic control adopts a cartridge valve integrated system, which is durable and has a long service life. Hydraulic press machine adopts buttons for centralized control, which can realize three operation modes: manual, semi-automatic and automatic.

Our Advantages

The overall box body mortise and tenon welding, steel plate thickness of more than 16MM, groove, each weld is welded more than 3 times.

After all the pressed vertical plate of the refrigerator shell is beveled, the multi-channel welding is carried out. The riveting hole is opened for the middle cylinder connecting plate, and the mortise and tenon filling welding is made. The weld is more full, the welding is more firm, and the deformation is reduced.

Hot Searches