1: Can we visit your factory?

Sure. We located in Dongguan city which is very near Guangzhou and Shenzhen. For overseas customers, you can fly to Guangzhou Baiyun or Shenzhen Baoan International Airport. We can pick you up in the Airport. We also provide visit online by video.

2: How can we get the exact price of plastic machine?

Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with quotation.

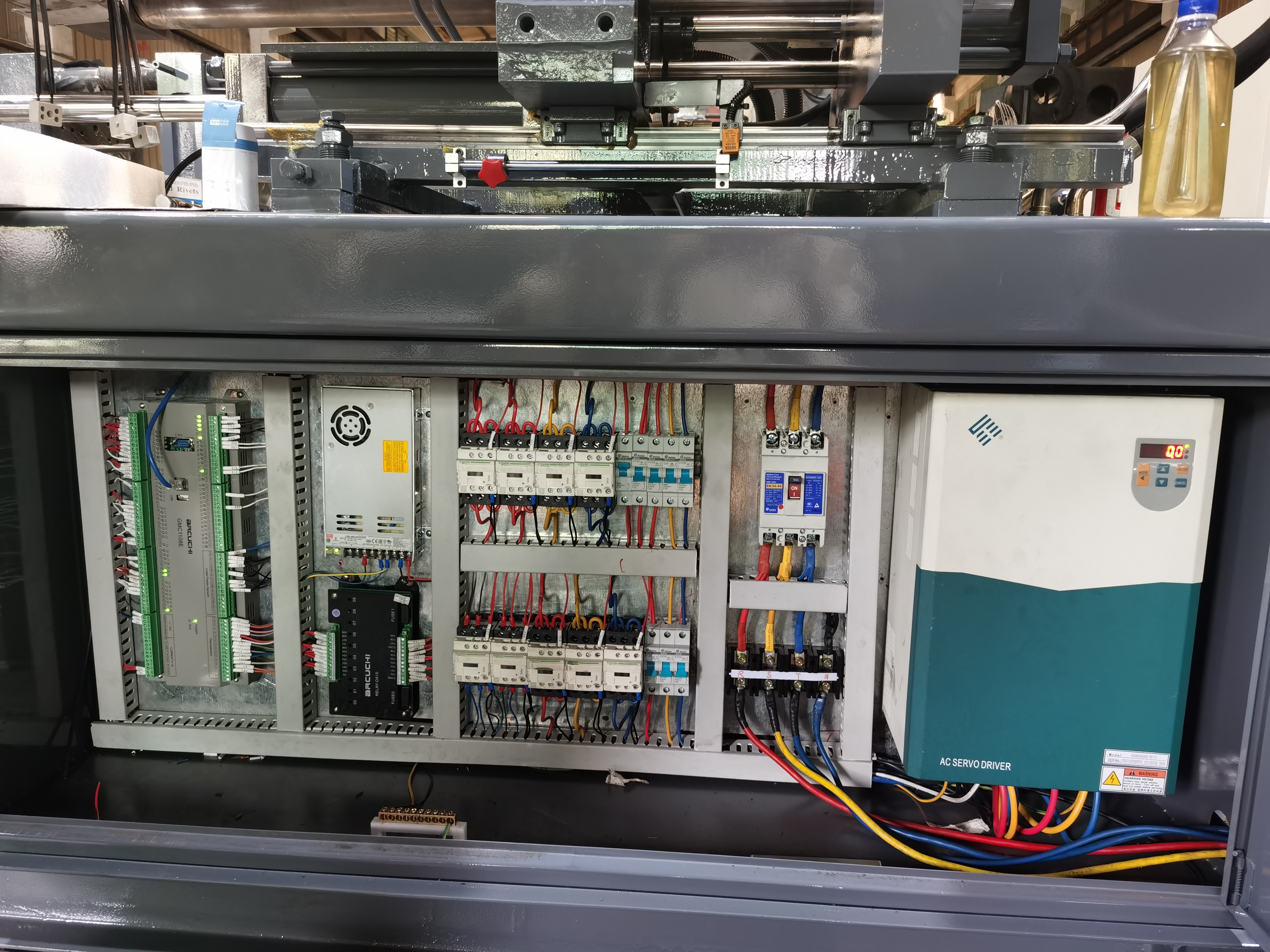

3: Do you provide any spare parts with machine?

Yes, we offer all necessary spare parts before shipment. (contact us for packing list )

4. What after-sale service can we provide?

--One year guarantee for the main parts.

--training customers' technical staff.

--24 HRS online support, video technical support

--On-site commissioning of the machine

5: Do you provide customized machines?

Most of our machines are customized. Our goal is to solve customer's production problem and material problems to improve the production efficiency. We design the machines according to customers products to meet customer's needs.

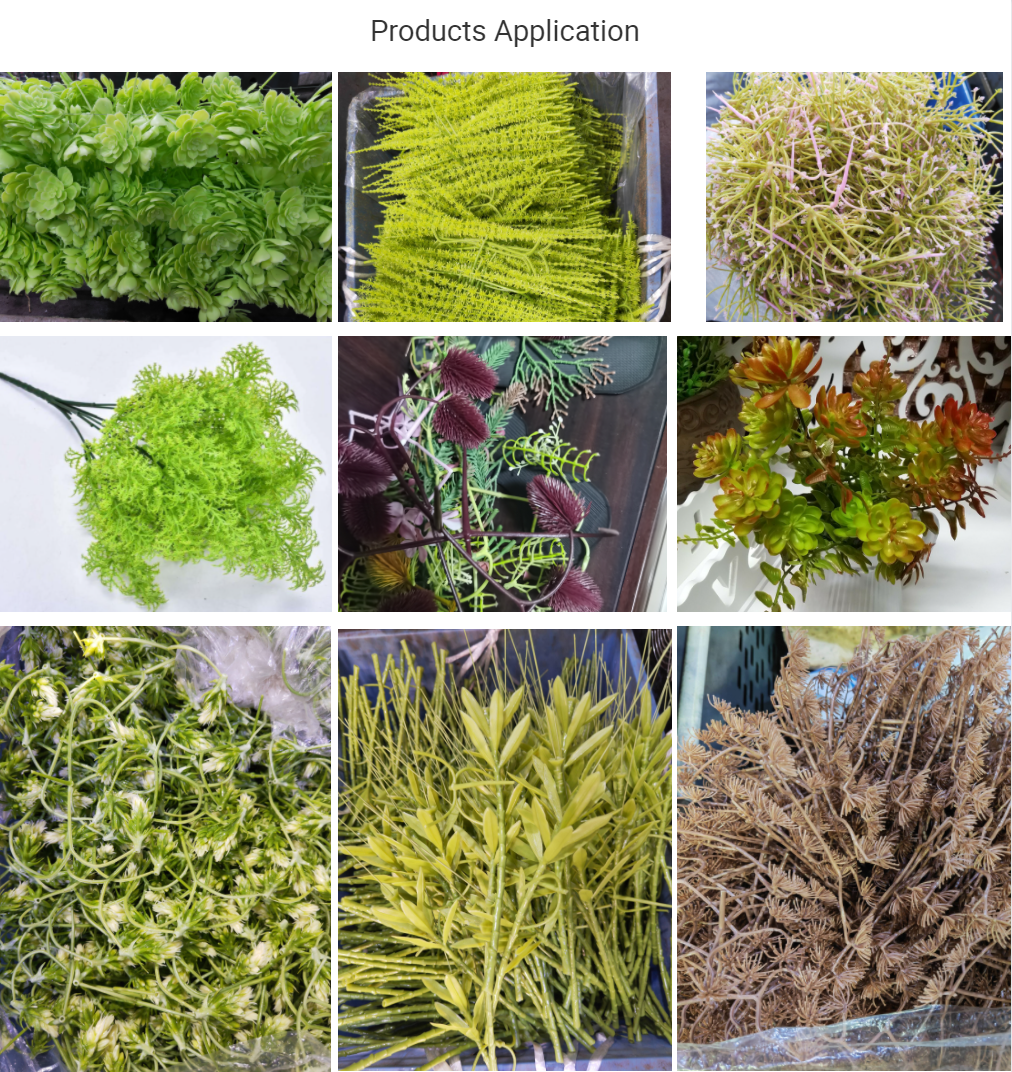

6. what kind of machine can you buy from us?

--Many series machine: all electric machine, two color machine, one color machine, mixed two color machine, two plate big tonnage machine, standard one color machine, injection and blow machine, plastic coated aluminum machine, liquid silica gel machine, vertical LSR machine, vertical multi-color/material machine. we are specialized in customized machine for special products.

7. How can we install the machine when it arrives?

We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the customer's employees.

8. why should you buy from us not from other suppliers?

--more than 30 years experiences.

--Solve your production problems in both material and shape.

--improve your production efficiency by 20%.

--save your energy (by all electric/improve speed/reduce the labor fee etc.0

--save your cost (by once forming/reduce painting/optimize production line

9. How to contact us?

whatsapp: +8615622758135

Wechat: 17188898889

Address: #1 BUILDING, DONGSHEN ROAD, QISHI TOWN, DONGGUAN CITY, GUANGDONG PROVINCE, CHINA.