- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Hochint

-

Voltage:

-

380V 50Hz

-

Dimension(L*W*H):

-

4880(+1650)*2100(+1650)*2350mm

-

Weight:

-

15000 kg

-

Warranty:

-

1 Year

-

Marketing Type:

-

Hot Product 2022

-

PLC Brand:

-

FATEK

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Max.sheet size:

-

1080*780mm

-

Min.sheet size:

-

400*330mm

-

Max. die-cutting size:

-

1075*770mm

-

Max. machine speed:

-

7000 S/H

-

Certification:

-

CE/ISO9001

Quick Details

-

Type:

-

Die-cutting Machine

-

Production Capacity:

-

7000 sheets/hour

-

Max. workable width:

-

780mm

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Hochint

-

Voltage:

-

380V 50Hz

-

Dimension(L*W*H):

-

4880(+1650)*2100(+1650)*2350mm

-

Weight:

-

15000 kg

-

Warranty:

-

1 Year

-

Marketing Type:

-

Hot Product 2022

-

PLC Brand:

-

FATEK

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Max.sheet size:

-

1080*780mm

-

Min.sheet size:

-

400*330mm

-

Max. die-cutting size:

-

1075*770mm

-

Max. machine speed:

-

7000 S/H

-

Certification:

-

CE/ISO9001

Application

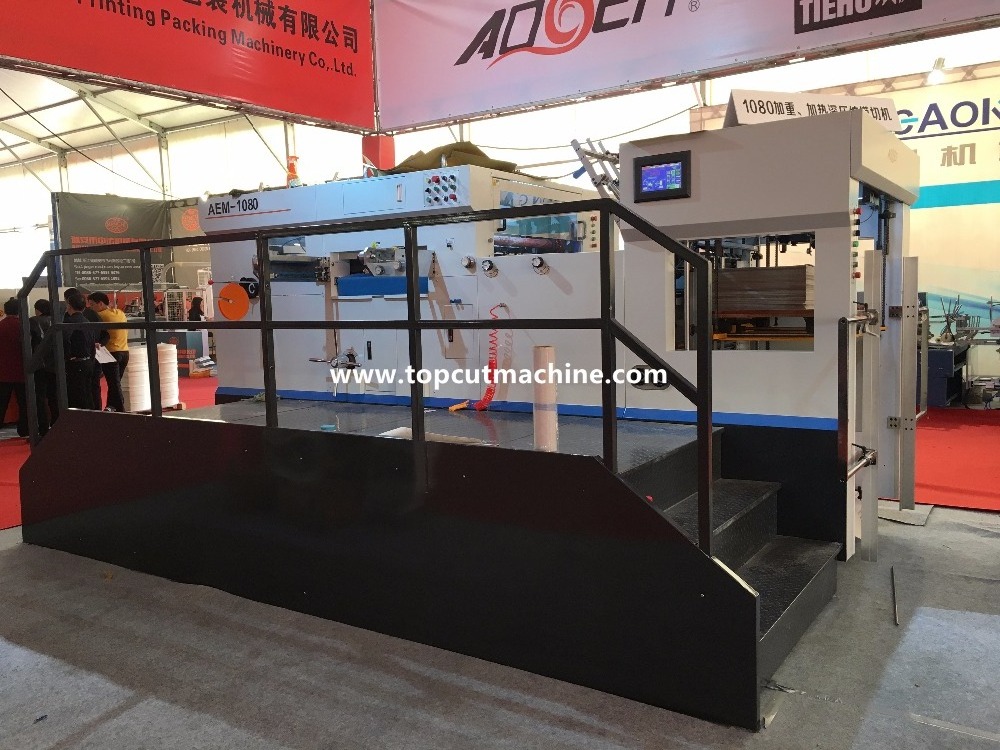

AEM-1080(Q) Automatic platen die cutting machine is used for die cutting various paper, paperboard, corrugated board, plastic sheet (like PVC, PP), with function of die cutting, creasing and embossing. The max die cutting speed can be 7000 sheets/ hour.

Specification

Features

1. Platen press is driven by Taiwan TECO main motor with Panasonic frequency convertor; the running of complete machine is controlled by PLC centralized controlling system which can automatically examine the working status and test unusual status as well as record the working condition. According to the Europe Safety Standard, we design reasonably to make the operability and safety perfect combination.

2. Advanced alarm system of starting up will remind operator to leave the unsafe area. Automatically detecting whole process, if malfunction, non-paper or paper stuck, the pneumatic clutch will separate and stop automatically which reduce the waste of paper, protect the staff and equipment.

3. Elaborate pre-stack device and paper feeding & delivery non-stop devices reduce the time of stacking, improve the efficiency of machine and increase your income.

4. Selected European, Japanese, and Taiwan electrical and pneumatic components improve the stability of the machine and reduce the frequency of maintenances.

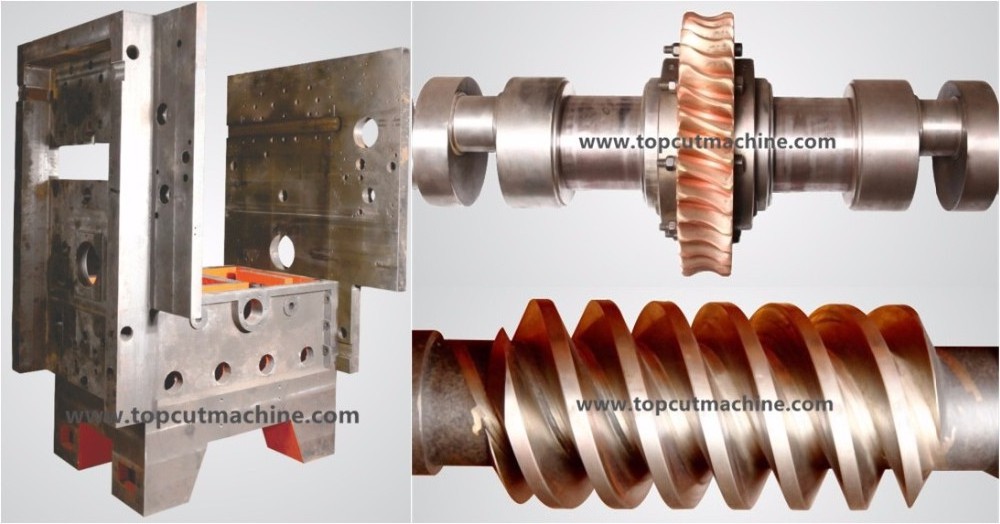

5. Mainframe and base adopt high strength spheroidal graphite iron QT500-7 which is accurately processed by numerical control centre, guarantee the machine run stably in long time when bearing 200T large pressure. The cores of the platen press machine such as crankshaft, worm gear and so on, are all imported high-class alloy steel, which are processed by quenching and high temperature tempering with a long working life.

6. Lubrication system for core parts is equipped with circulatory oil cooling system, which can reduce the rejection rate and prolong the working life of parts. It is also equipped with display device for oil pressure and alarming device for insufficient pressure of oil and air.

7. Supply long-term and complete technical training as well as prompt free maintains for one year, guarantee that our clients can fully master the production technology of our equipment. Our machine is with Perfect design, accurate installation, high stability, high security, low noise.

Detail Images

Pressure-bearing part is made of high ductile iron QT500, high strength, never deform; wear resisting crankshaft and worm gear.

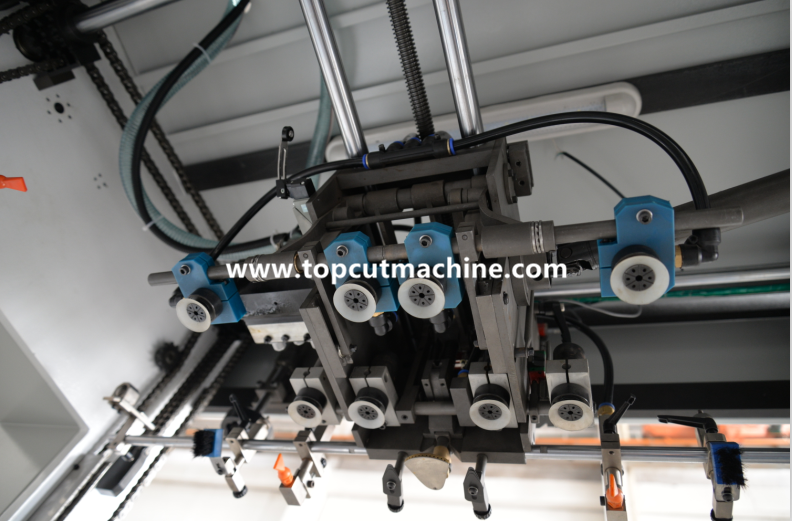

It can adjust angle and height of suction nozzle according to the paper distortion which is suitable for both paperboard and corrugated paper.

Human-friendly design for die frame & baseplate and convenient die flipping device, makes installation, adjustment convenient.

Pneumatic die locking device, die frame can be fixed more steadily, accurately and time saving.

Import gripper bar chain and High hardness, strength Ti-Al alloy gripper.

PLC centralized controlling system can automatically examine the working status and test unusual status as well as record the working condition.

Packing & Delivery

1. metal pallet

2. vacuum bag packing

3. total machine can be loaded into 40GP.

RUIAN AOER is located at Ruian, Wenzhou –Machinery Capital of China. AOER founded in 1995, specializes in researching and manufacturing die cutting and foil hot stamping equipment, Nowadays, there are “ML”, “TYM”, “QPM”, “AEM” four series of our products, including manual, semi-automatic, full automatic, hot stamping totally more than one hundred different models for your choice. Our machines are used for die cutting and foil stamping in post-press industry and carton packaging industry.

AOER, after more than 20 years’ development, has become the National Hi-Technology Enterprise combining research, production, marketing and is one of the biggest manufacturers of die cutting and hot stamping equipment in China. Now AOER brand is Wenzhou famous brand and AOER products are sold well both in China and international markets.

AOER owns modernized workshops covering an area of 16,000 ㎡ and 150 staffs including 20 professional technicians. AOER guarantees the quality in the whole process of production. We can offer more than 100 types of high-quality die cutting machine and hot stamping machines, and we are the qualified supplier for more than 500 enterprises, like STARLITE Group, MYC group, YUTO group, HUNG HING group, and BYD company, etc.

AOER, in the future, will move forward on the road of innovation and provide first-class products, service and infinite values for you.

Pre-sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Warranty

Machines are new (or unused) and the guarantee period will be given thirteen months from shipment date. During this period, the seller will provide free maintenance and free spare parts that caused by the machine's quality, but the buyer must pay the courier cost. Parts damaged because of mishandling and consumable parts are not covered by any warranty.

All our machines have CE certificates and passed ISO9001-2008

Welcom you visit our factory to test machine by yourself!

.AEM-800 full auto die cutting machine

ML-1100 manual die cutting machine

TM-1080D full suto stripping machine