- Product Details

- {{item.text}}

Quick Details

-

Usage:

-

Stone Cutting

-

Application:

-

Blasting

-

Quality:

-

Guaranteed

-

Key words:

-

Mining Drill Rod Top Performance

-

OEM:

-

Accept OEM

-

MOQ:

-

1 Piece

-

Customized:

-

Support Customization

-

Advantage:

-

High Performance

-

Process:

-

High-heat Treatment

Quick Details

-

Weight (KG):

-

500

-

Place of Origin:

-

Sichuan, China

-

Product name:

-

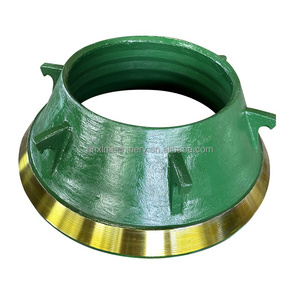

Bowl Liner

-

Usage:

-

Stone Cutting

-

Application:

-

Blasting

-

Quality:

-

Guaranteed

-

Key words:

-

Mining Drill Rod Top Performance

-

OEM:

-

Accept OEM

-

MOQ:

-

1 Piece

-

Customized:

-

Support Customization

-

Advantage:

-

High Performance

-

Process:

-

High-heat Treatment

Product Description

Zhixin mining machinery spare part Bowl liner

The crusher will make a trajectory movement, sometimes approaching and sometimes far away from the bowl liner, so as to squeeze the crushed materials, and part of the materials will be discharged from the open side discharge port. There are U-shaped screws on the bowl liner of the adjusting ring, and zinc alloy is injected between the two to make them tightly combined.

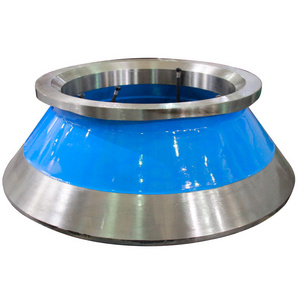

Broken cone

One of the main components of the crusher, also known as the moving cone, is fixed on the cone body with the cone head. The conical broken wall is forged by new composite material, which has the characteristics of abrasion resistance, high cost performance and wide application field. The cone breaking wall is fixed on the cone body by the cone head, and epoxy resin is cast between them.

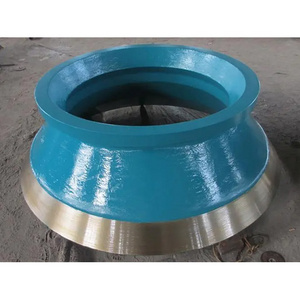

Rolled mortar walls are and broken walls

The milling wall and the crushing wall are the main parts that work together in the cone breaking to break the material, and they are also called fixed cones because they are fixed. When the cone is in operation, the broken wall will do a trajectory movement, and the distance from the rolling wall is sometimes close to and sometimes far away, to squeeze the broken material, and some materials will be discharged from the open edge discharge port. A U-shaped screw is placed on the adjusting ring, and zinc alloy is injected between the two to make them tightly bonded.

Hot Searches