- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

WEIHONG/CYPCUT

-

Cutting Area:

-

Other

-

Control Software:

-

CYPTUBE CNC system

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

CHITTAK

-

Weight (KG):

-

4000 KG

-

Feature:

-

Automated Loading/3D/Water-cooled/Servo-motor

-

Product name:

-

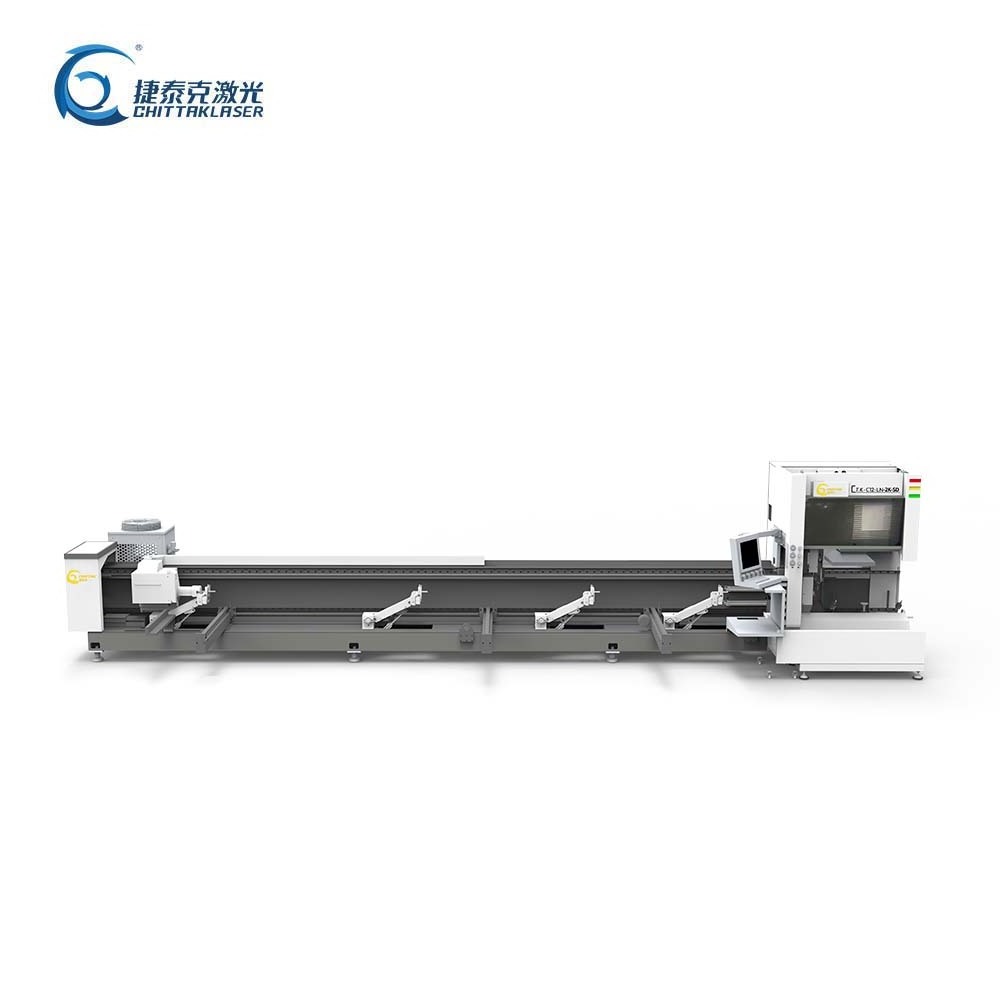

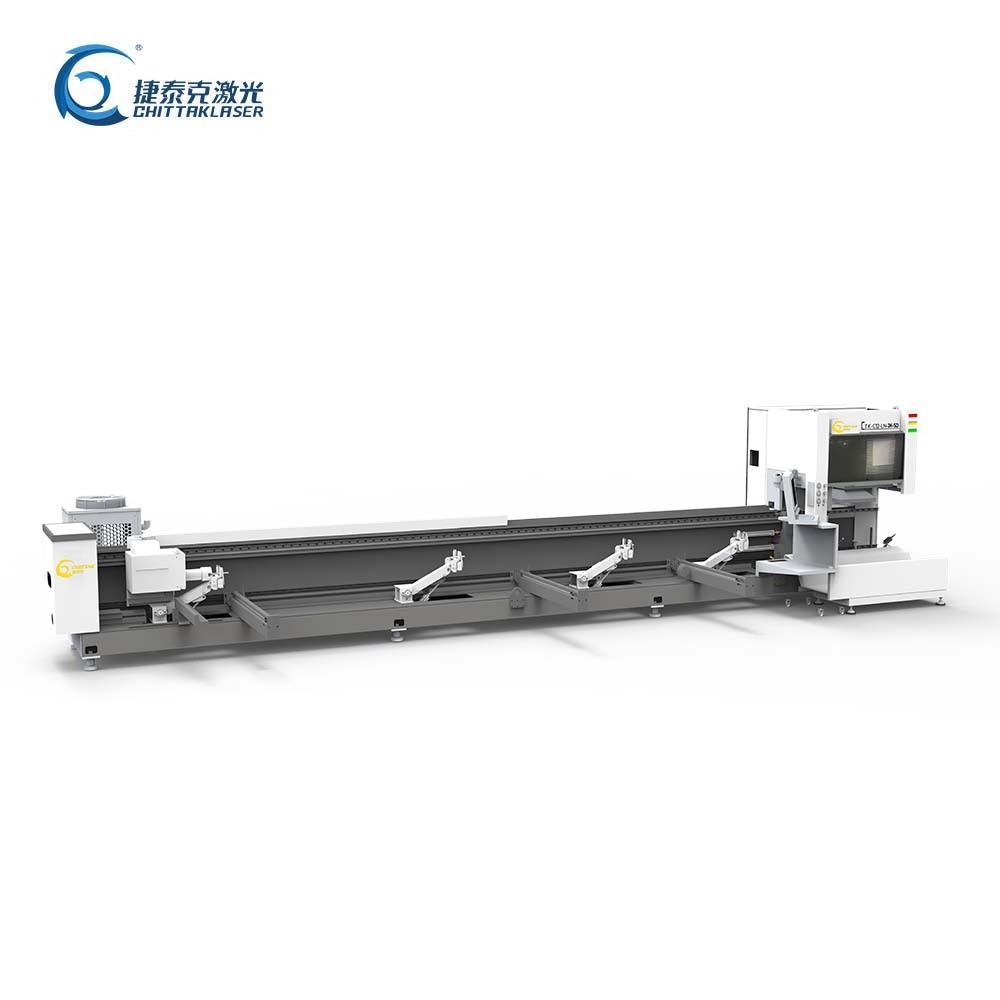

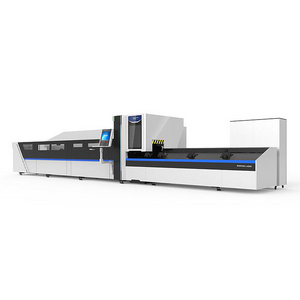

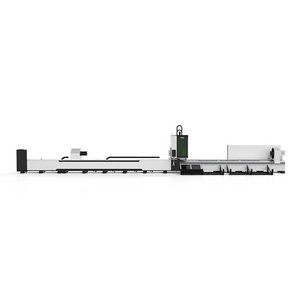

High performance 3D automatic laser pipe cutting machine

-

Cutting materials:

-

Stainless Steel Carbon Steel Aluminum

-

Laser head:

-

Ospri

-

Control system:

-

Cyptube Control System

-

Cutting pipe shape:

-

round pipe/Square pipe/rectangular pipe

-

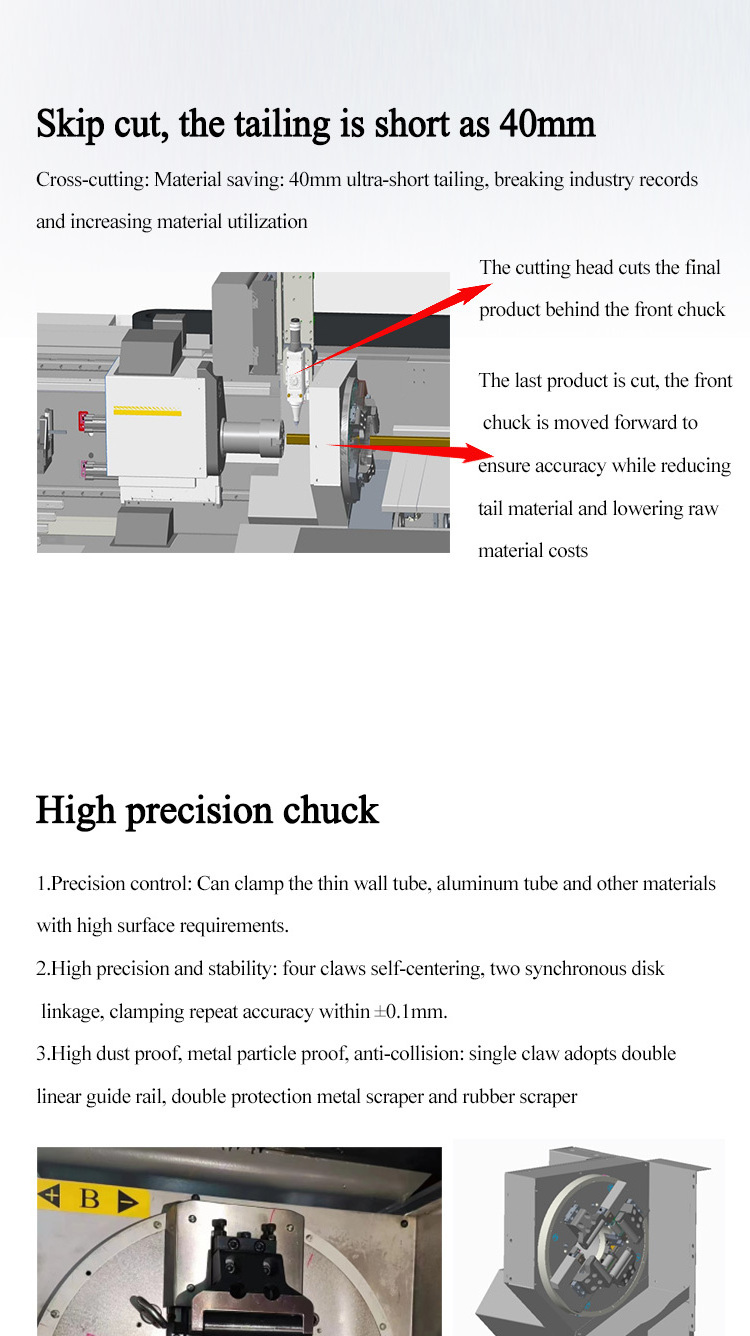

Cutting tail length:

-

40mm

-

Cooling machine:

-

Hanli/Blue penguin

-

Fiber laser generator:

-

BWT

-

Intelligent bus system:

-

easy to learn and use

-

Left/right model customization:

-

save floor area and save people and space

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

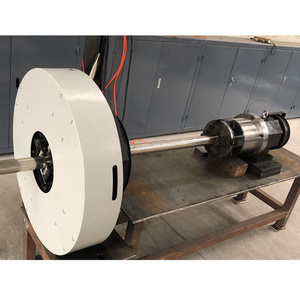

Maximum speed of chuck:160rpm/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

WEIHONG/CYPCUT

-

Cutting Area:

-

Other

-

Control Software:

-

CYPTUBE CNC system

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

CHITTAK

-

Weight (KG):

-

4000 KG

-

Feature:

-

Automated Loading/3D/Water-cooled/Servo-motor

-

Product name:

-

High performance 3D automatic laser pipe cutting machine

-

Cutting materials:

-

Stainless Steel Carbon Steel Aluminum

-

Laser head:

-

Ospri

-

Control system:

-

Cyptube Control System

-

Cutting pipe shape:

-

round pipe/Square pipe/rectangular pipe

-

Cutting tail length:

-

40mm

-

Cooling machine:

-

Hanli/Blue penguin

-

Fiber laser generator:

-

BWT

-

Intelligent bus system:

-

easy to learn and use

-

Left/right model customization:

-

save floor area and save people and space

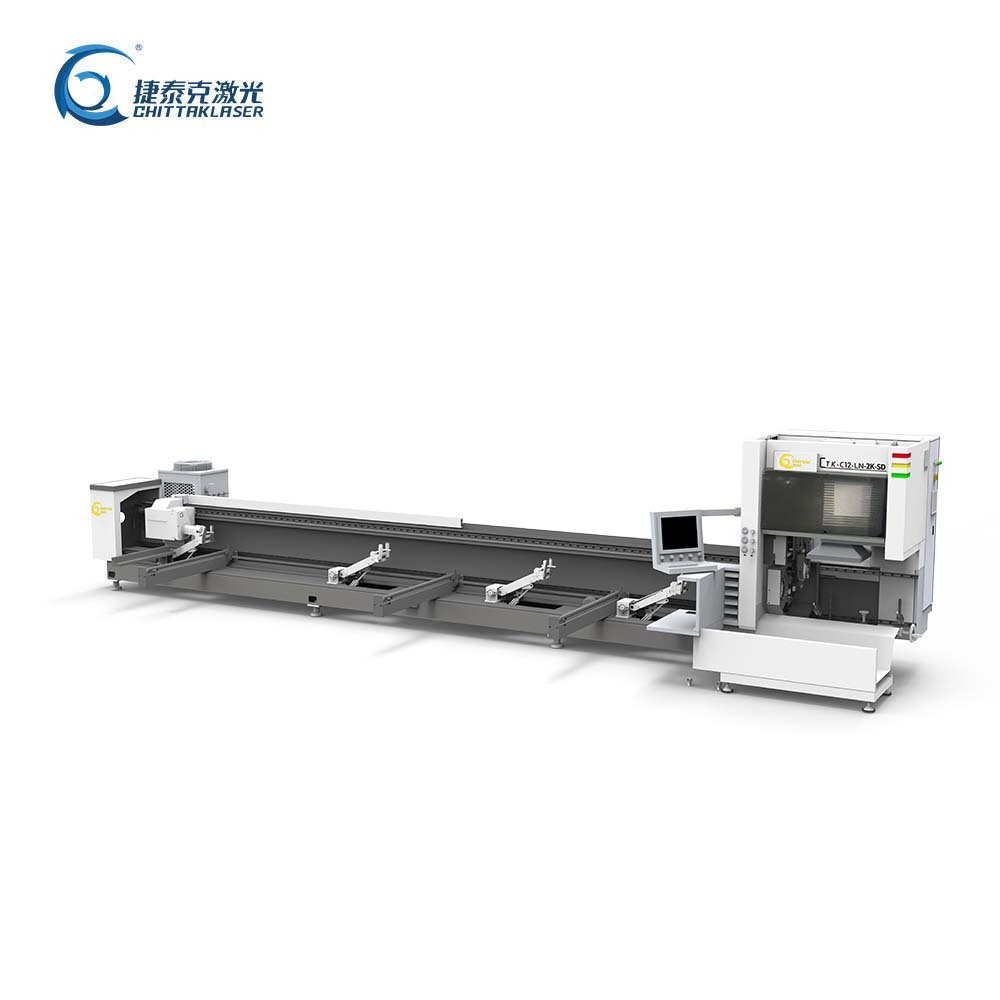

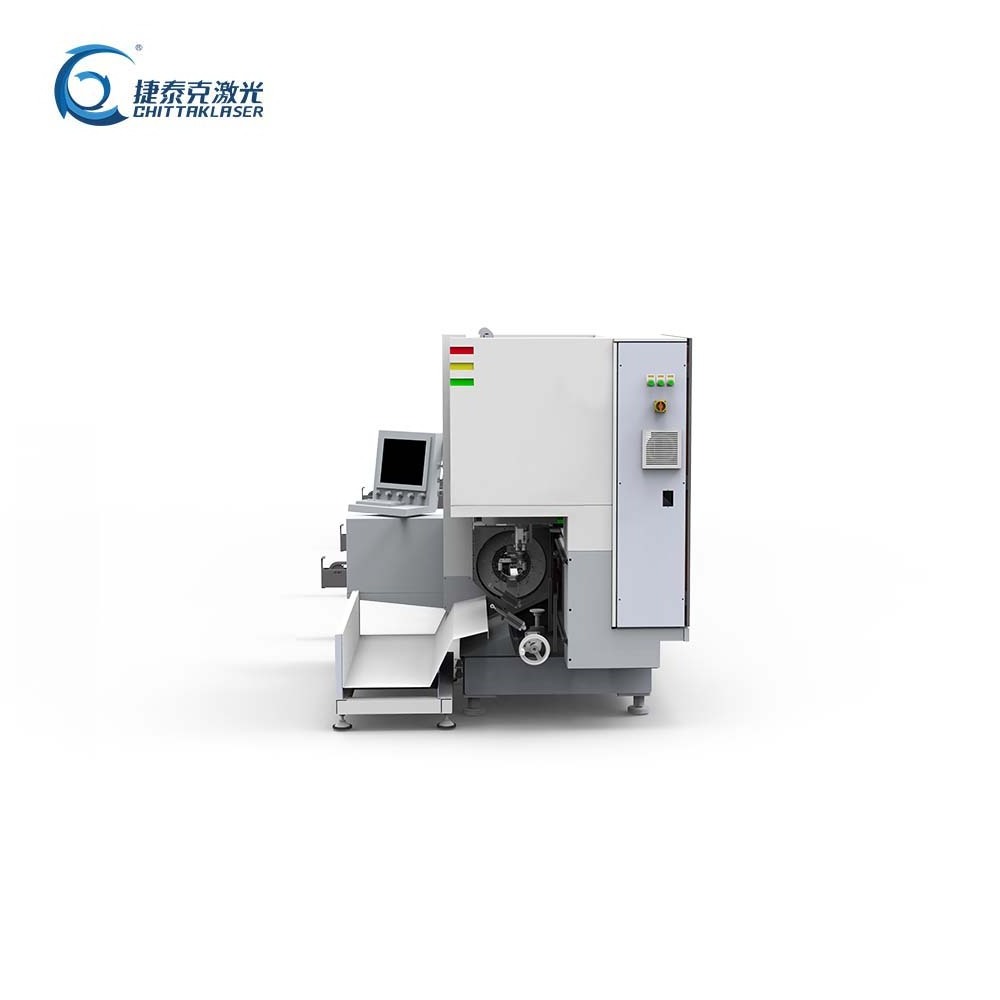

1.High speed: Chuck speed, cutting efficiency, standard configuration, and machine price all have high competitive advantages. 2.Material saving: 40mm ultra-short tail material, breaking industry records and increasing material utilization

3.High range compatibility: diameter10~120mm pipe diameter, compatible with round pipe, square pipe, oval pipe, special-shaped pipe, etc., with obvious advantages for thin-walled pipes.

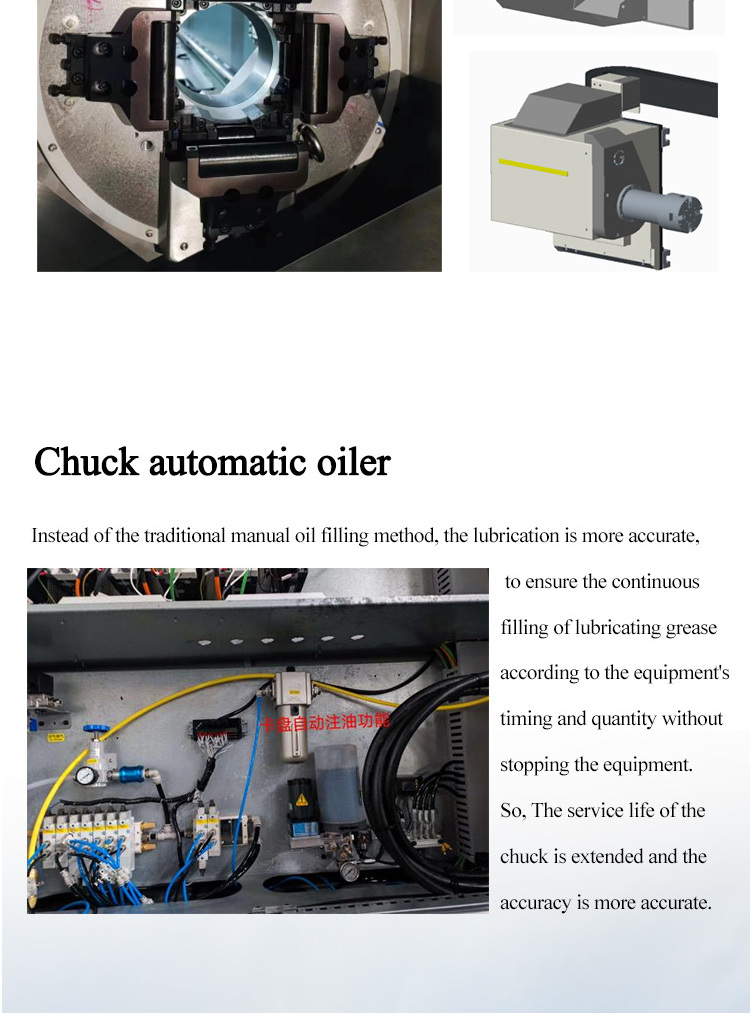

4.High-precision chuck: one-time clamping, no need to replace the jaws, long-term accuracy.

5.Automatic feeding: The structure of the side-mounted machine tool is equipped with a semi-automatic feeding machine as standard, and the feeding does not need to be stopped, and it can realize 24-hour non-stop operation.

6.Low cost: No high-cost consumables, the main losses are electricity bills, protective lenses and copper nozzles (13-15 RMB per hour).

| Model | C12-LN-2K-QD |

| Laser power | 1500W/2000W/3000W |

| Pipe processing range |

Round tube: φ10mm-φ120mm; Square tube: side length 10mm-80mm; Special-shaped tube: circumscribed circle≤φ120mm |

|

Semi-automatic feeding range |

Round pipe diameter:16mm-120mm Square pipe side length:16mm-80mm Special-shaped tube:Outer circle diameter≤120mm Feeding length:5800-6200mm |

| Manual feeding(mm) | 7000 |

| Automatic feeding length(mm) | 5800~6200 |