- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

85-365 Kw

-

Dimension(L*W*H):

-

20*8*8 m

-

Weight:

-

175000 kg

-

Features:

-

easy operated

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Working condition:

-

Stable and safe

-

Advantage 1:

-

High Efficiency,energy and labor saving

-

Advantage 2:

-

Fireproof,Thermal Insulation,sound insulation

-

Raw material:

-

Natural Gypsum Ore

-

Type:

-

Full-automation

-

Technology:

-

Boiling Furnace

-

Price:

-

Competitive

-

Fuel:

-

Oil Gas Coal

-

Experience:

-

Over 20 years

Quick Details

-

Application:

-

gypsum power production

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DAFU

-

Voltage:

-

380V

-

Power:

-

85-365 Kw

-

Dimension(L*W*H):

-

20*8*8 m

-

Weight:

-

175000 kg

-

Features:

-

easy operated

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Working condition:

-

Stable and safe

-

Advantage 1:

-

High Efficiency,energy and labor saving

-

Advantage 2:

-

Fireproof,Thermal Insulation,sound insulation

-

Raw material:

-

Natural Gypsum Ore

-

Type:

-

Full-automation

-

Technology:

-

Boiling Furnace

-

Price:

-

Competitive

-

Fuel:

-

Oil Gas Coal

-

Experience:

-

Over 20 years

2023 Great-quality High Effective Large Production Capability Gypsum Powder Production Line Manufacturer Plant

Gypsum powder is one of five gel materials, occupies an important position in the national economy, widely used in construction, building materials, industrial mold and art model, chemical industry and agriculture, food processing and medicine and other cosmetic applications, is an important industrial raw materials.

The gypsum powder machinery is a new type production line. With the development of gypsum industry, there is a large demand for quantity and high quality of gypsum powder. Therefore, the high level of gypsum powder production technology is required.In the process of gypsum powder production, drying and dewatering is the key link, which is also the most difficult one to control. In order to solve this problem, we develop a new type of drying and dewatering equipment---ebullience calciner, which is produced based on the exploring of the gypsum production filed.

Main S pecification

|

Model |

Power (KW) |

QTY (PCS) |

|

|

Jaw crusher |

PE400*600 |

30 |

1 |

|

Hammer crusher |

PC800*600 |

55 |

1 |

|

Conveyor |

SW600*15M |

15 |

1 |

|

Raw material storehouse |

10 ton |

|

1 |

|

Hydrated gypsum Storehouse |

20ton |

|

1 |

|

Raymond mill |

|

145 |

2 |

|

Ebullience calciner (including Roots blower) |

20T/H |

22 |

1 |

|

|

|

1 |

|

|

Hoister |

|

22 |

2 |

|

Final products storehouse |

|

|

3 |

|

Electromagnetic feeder |

|

7.5 |

2 |

|

Hoister |

350*18M |

|

1 |

|

|

45 |

1 |

|

|

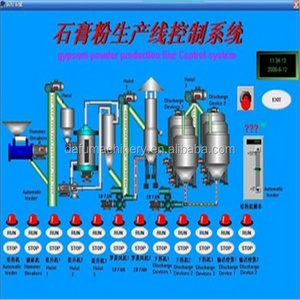

Electrical control system |

|

|

1 |

Analysis on technique features

I. Concept of technique

Crusher grinds large gypsum into small granules less than 25mm. After storage and measurement with weigh belt, transfer them into Raymond mill for milling. Transfer qualified calcined gypsum powder to clinker bin for storage or to board-manufacturing workshop for usage.

II. Technique’s advantages:

1.Features of first grind and second bake:

Compared with that of first grind and second bake, the largest advantage of this technique is great energy consumption reduction. The reason lies in: great plaster stones are ground into powders with diameter less than 0.2mm, which increases the specific surface when calcining, enlarges contact area with heat medium, improves calcining heat exchange efficiency and lowers energy consumption greatly; the disadvantages are three powder pollution positions in technical process, which shall be solved with dust-removing equipment.

2.Features of two other techniques:

First bake and second grind: due to high energy consumption and low production capability of this technique and that the quality of the products is hard to control and is unstable, at present, it is a kind of backward technique and is seldom adopted. Only a few small factories are still applying it.

Integration of grind and bake: this technique has good features: low energy consumption, small investment, high efficiency, stable quality of the products and small area coverage. Besides, the dust volume is concentrated and is easy for protecting environment. However, it is not mature at home and only BNBM imported from German one set of Peters-mill, which runs to manufacture thistle board.

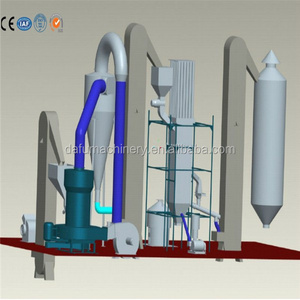

The main photos of the gypsum powder production line

ebullience calciner

dust collector

heat-conducting oil boiler

The others machines

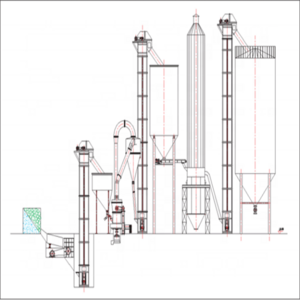

The flow chart of gypsum powder production line

After service

1. Our company has professional installation team. We will install and test the production line at the customers’ place until the equipment produces the qualified products.

2. We supply the accessories all the year round. The warranty of the equipment is one year.

3. We are responsible for the technical consultation and service all the year round and solve all kinds of technical problems at any time.

4. We can help the customer to do the consignment and the relevant procedure for import and export.

5. Our company will supply the information of the seller for all kinds if raw materials and relevant information.

6. The Operating Instruction will go to the customers with the equipment