- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

0.5ml

-

Voltage:

-

220V/380V/415V/480V 3P

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

JUST

-

Dimension(L*W*H):

-

2700mmX2000mmX2200mm

-

Weight:

-

3500 KG

-

Warranty:

-

2 year, life-long technical support

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

name:

-

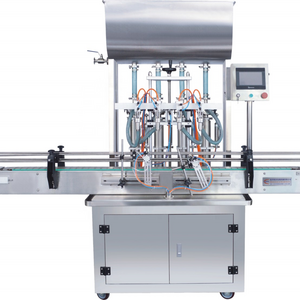

mineral water bottling machine

-

Product name:

-

mineral water bottling machine

-

Function:

-

mineral water bottling machine

-

Material:

-

Stainless Steel 304/316

-

Bottle type:

-

PET Plastic Bottle/Glass bottle

-

Capacity:

-

1000-36000 bottles per hour

-

Usage:

-

water filling machine

-

Processing Types:

-

mineral water bottling machine

-

Filling material:

-

drinking water/drinks

-

Certification:

-

CE ISO U L

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 2000BPH, 1000BPH

-

Packaging Material:

-

Plastic, Wood

-

Filling Material:

-

Milk, Water, Juice

-

Filling Accuracy:

-

0.5ml

-

Voltage:

-

220V/380V/415V/480V 3P

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

JUST

-

Dimension(L*W*H):

-

2700mmX2000mmX2200mm

-

Weight:

-

3500 KG

-

Warranty:

-

2 year, life-long technical support

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

name:

-

mineral water bottling machine

-

Product name:

-

mineral water bottling machine

-

Function:

-

mineral water bottling machine

-

Material:

-

Stainless Steel 304/316

-

Bottle type:

-

PET Plastic Bottle/Glass bottle

-

Capacity:

-

1000-36000 bottles per hour

-

Usage:

-

water filling machine

-

Processing Types:

-

mineral water bottling machine

-

Filling material:

-

drinking water/drinks

-

Certification:

-

CE ISO U L

Complet Automatic Drinking Water Filling Machinery Line:

XGF Bottle Washing Filling Capping 3 IN 1 machine:

Washing Part :

<1>360 degree cleaning inside and outside of the bottle,no dead Angle.

<2>All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean .<3>The flushing pressure can be adjusted.

<4> 304/316 stainless steel washing pump make the machine more durable .

Filling heads :

<1> 304/316 Stainless steel high precision filling nozzle.

<2> Filling volume adjustable in fine rank, same liquid level after filling.

<3> All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean.

<4> 304/316 stainless steel filling pump.

Capping heads :

<1> Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

<2> All 304/316 stainless steel construction<3> No bottle no capping

<4> Automatic stop when lack of bottle

<5> Italy ROAL capping hard,capping effect is stable and reliable,Defective rate ≤0.1%

Flat conveyor :

<1> Adapt to customer factory layout.

<2> Special lubrication system, keep products clean, health, safety,extended service life

<3> Electric eyes design keep whole line running safety and quickly,Energy saving. High efficient.

<4> Overload protection mechanism to effectively ensure the safe of the machine

<5>All Stainless steel 304 support, hygienic/firm

Air conveyor :

<1> Air conveyor is fixed on the floor, with fan installed on the top.

<2> Air filter is positioned at every entrance of air fan, to prevent dust blown into bottles. Bottles are held on the neck in the conveyor and transported into filling machine by blowing power.

<3> All are made of stainless steel SUS 304 /316.

Blow molding system :

Full automatic blow molding machine is suitable for producing PET plastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc.

Bottle Unscrambler :

<1> Don't change the mould can arrange similar size different shape bottles.

<2> High speed and lower rate of waste.

<3> small occupied area. machine is arranged flexibly placement saving the area of factory.

<4> automatic intelligent design,The function of preventing bottle.photoelectric detection to run more smoothly.

Automatic labeling machine:

<1> Heat shrink sleeve labeling machine

<2> OPP Hot melt labeling machine

<3> PVC label stick labeling machine

It adopts double driving structure ,that is four-wheel driving, self-centering and balanced pressure of four wheels. It can achieve the good effect of transmission of labels smoothly, stably and rapidly.

Bottle packaging machine :

<1> PE film/Half-tray shrink wrapping machine

<2> Carton box packaging machine

It adopts the photoelectric sensor to detect online, gather signals which are controlled by PLC, and adopts piston as executable element, to realize product conveying, combination, film wrapping, cutting, heat& shrink, cool and finally get the finished product.

We are capable of providing specialized proposal design and make a general budget for you.

Q2: Equipment production&commissioning

We will arrange the production for you as soon as the order confirmed, and make sure the quality of products, We have client cases in different countries , we can provide theirproduction working video for you .

Q3: Factory layout design

Machines and factory layout design is also available after the proposal confirmed.

Q4: Bottle shape design

We can also help to do the bottle shape design for you according to your needs.

Q5: Label Design

We can also help to design the label for you, and you can share with us your idea too.

Q6: Raw Material supply

1, the guarantee of our machines is two years, life-long services, also we will supply spare parts along with the machines free of charge, the parts will be enough for at least 3 years for the normal operation of machines.

2, we can train your engineers in our factory free of charge. IMeans you can send your engineers to our factory to study and training, we have rich experiences for the training, it is the good way to make sure that you can operate and maintain our machines successfully and for long time normal use.

3, we will supply you detail user manual for our machines, also we will make one Video CD to show you how to install and maintain the machines, it will help you to maintain the machines for the long time.

4, We will send our engineers to your factory to install the machines and train your staff how to operate the machines., We have been doing the install jobs for our overseas customers for many years.

5. We will help to arrange the shipping of goods for you and keep you posted about the steps.

Q2: How long of your warranty?

A2: Regarding warranty, normally we offer 2 years warranty, and we offer lifetime maintenance.

Q3: Can you provide turnkey project service?

A3: Yes, of course, we can provide the full set of turnkey project service to you, from raw material, to equipments, installation nd training etc.

Q4. Do you accept OEM order?

A4: Yes, we have strong design team and technical team. Therefore we can also accept OEM and customized order with special requirements.

Q5: What else need to be paid attention besides price?

A5: except for the price, we also need pay attention to quality, product construction, design principle, configuration of part list, reasonability, convenience of operation, professional, service and etc.