- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

0.01MM

-

Voltage:

-

380V 50Hz

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

B&E

-

Dimension(L*W*H):

-

1800*1000*1500mm

-

Weight:

-

100 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Function:

-

Washing Filling Capping

-

Usage:

-

Beverage Packaging

-

Filling material:

-

Flowing Liquid

-

Bottle type:

-

Gallon Bottle

-

Material:

-

SUS304

-

Capacity:

-

100-150bph

-

Marketing Type:

-

New Product 2020

Quick Details

-

Machinery Capacity:

-

500BPH, 200BPH

-

Packaging Material:

-

Plastic, Wood

-

Filling Material:

-

Water

-

Filling Accuracy:

-

0.01MM

-

Voltage:

-

380V 50Hz

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

B&E

-

Dimension(L*W*H):

-

1800*1000*1500mm

-

Weight:

-

100 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Function:

-

Washing Filling Capping

-

Usage:

-

Beverage Packaging

-

Filling material:

-

Flowing Liquid

-

Bottle type:

-

Gallon Bottle

-

Material:

-

SUS304

-

Capacity:

-

100-150bph

-

Marketing Type:

-

New Product 2020

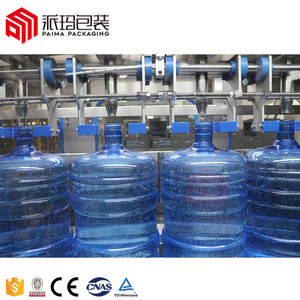

BS-1 5gallon brusher

Technical Parameter:

Model:BS-1

Material:AISI stainless steel 304

Power:0.75kw

Suitable products:According customer products size.

Capacity :100-240 pc per hour

Size:800x700x1200mm

Weight:80kg

19L/20L water bottle filling line 5 gallon water bottle filling machine factory price

1. Composition: Decapper; Auto-loader; Bottle Washer; Filler; Capper.

(P.S. : Accessory equipments can be supplied here such as bottle blowing machine, labeling machine, bottle ink-jet coder, inspection lamp, air conveyor, bottles conveyor, cases conveyor, case ink-jet coder, change parts for various bottles, etc.)

2. Control System: PLC

3. Decapper/ Auto-Loader/ Bottle Washer/ Filler/ Capper Introduction:

a. Decapper: Remove covers with piston connected with cylinder moving upwards and dowards; Safely controlled by PLC SYSTEM;

b. Auto-Loader: Auto-loading chains, precise bottle spacing and locating; Precise loading without friction at the bottom of bottle; CYLINDER-CONTROLLED reversible loading

c. Bottle Washer: 2 rinsing cycles; Washing both inside and outside under AUTOMATIC WATER LEVEL CONTROLL with detergent of temperature adjusted by sensors around 70°C; Final rinsing with spring or ozonized water (Ozone generator optional); Spraying nozzle eliminating the residual water of bottle via air blower;

d. Filler: Overflow pressure filling system; Filling accuracy of 99%;

e. Capper: Linear capping machine for press-on caps; Equipped with cap unscrambler and caps chute for distributing caps.

1.Can your factory provide he whole plant from A to Z?

Yes, we can provide the complete plant, from bottling making plant,water purification plant,to filling packing plant.

2.Are all machinery your factory made?

Our factory make the water purification and filling packing plants.we do not make the bottle making machinery,we have good quality bottle making machinery partner,and we provide to customer same long warranty time and good after service.

3.How can i know the machinery quality before i order?

First,we will invite you visiting our factory to check the machines quality,and show the machines running for you in our factory.

4.What certificates you can provide?

Our factory provide the CE,SGS,ISO,and according to some countries,we also can provide the PVOC, COC,SONCAP...ect.

5.Can your factory make the bottle drawing,workshop layout ,and labels for us?

We can help customers design their own bottle shape,workshop layout and label drawings,these jobs are free charge.(workshop need customer to provide the size of factory)

6.Installation and training time

We have professional engineer for oversea installing and training,the can speaking English,and have much experience oversea work.