- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

500*1300*2500mm

-

Year:

-

2019

-

Weight (KG):

-

18000 kg

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Service:

-

Field maintenance and repair service

-

Support:

-

Site and Online support

-

Application:

-

Tire cutting recycling

-

Process materials:

-

used tyre/rubber/wood/plastic

-

Capacity:

-

100-2000KG/H

-

Blades material:

-

H13/D2 or as required

-

OEM:

-

Yes

-

Shredder Type:

-

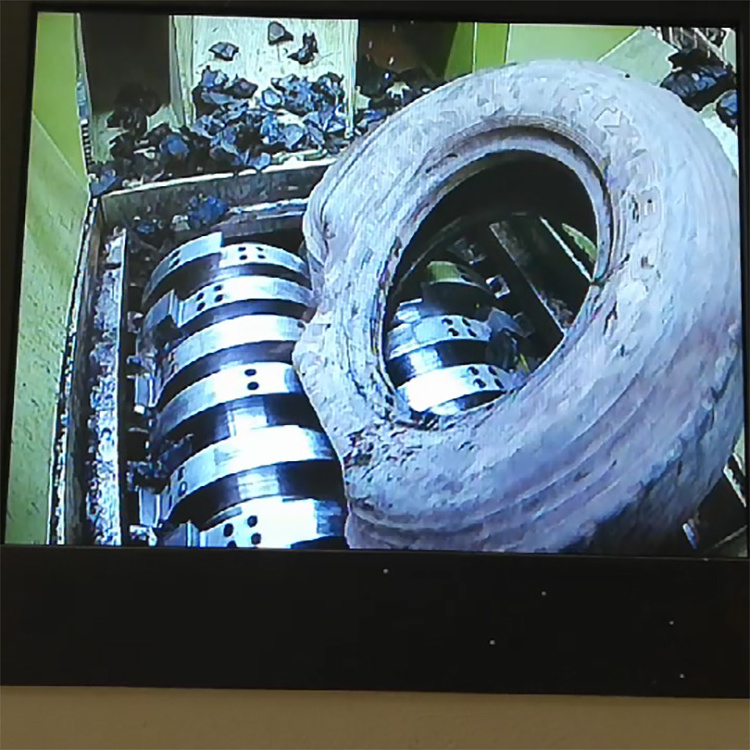

double shaft shredder for tire cutting

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Optima

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

500*1300*2500mm

-

Year:

-

2019

-

Weight (KG):

-

18000 kg

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Service:

-

Field maintenance and repair service

-

Support:

-

Site and Online support

-

Application:

-

Tire cutting recycling

-

Process materials:

-

used tyre/rubber/wood/plastic

-

Capacity:

-

100-2000KG/H

-

Blades material:

-

H13/D2 or as required

-

OEM:

-

Yes

-

Shredder Type:

-

double shaft shredder for tire cutting

Low price used tyre shredder rubber tire recycling equipment 2000kg/h

Product Application

Waste Tire Shredder adopts PLC automatic control and have the function of start/ stop reverse and overload automatic reverse. The advantage of this machine are low speed, large torque and low noise. This machine is suitable for the thick and hard materials, such as hard disk, engineering plastics, household appliances, plastic head material,etc.

This kind of shredder is the ideal solution for:

1. Metals: <4mm carbon steels, copper and aluminum products, etc.

2. Plastics: ABS, PS and other plastic cases of waste office appliances, etc.

3. Waste Office Appliances: Printers, duplicators, fax machines, etc.

4. Waste Home Appliances: Refrigerators, air conditioners, washing machines, fans, etc.

5. Waste Electronic Equipment: Computers, mobiles, Game players, etc.

6. Woods: Wooden furniture, wooden trays, etc.

7. Other wastes: Rubber tyres, card boards, PCB, leather, fiber glasses, solid urban wastes, etc.

Main Features of Waste Shredder

1. Low speed,high torque.

2. Low noise,low dust and low heat generation.

3. The wear-resistant cutters are made from robust die steel that can shred various kinds of materials easily.

4. Bulk feed capacity.

5. A hydraulic unit helps to push the materials into the hopper so that the efficiency is promoted.

6. A separate control cabinet with Siemens PLC in.

7. Shock protection: Auto reverses against overfeeding.

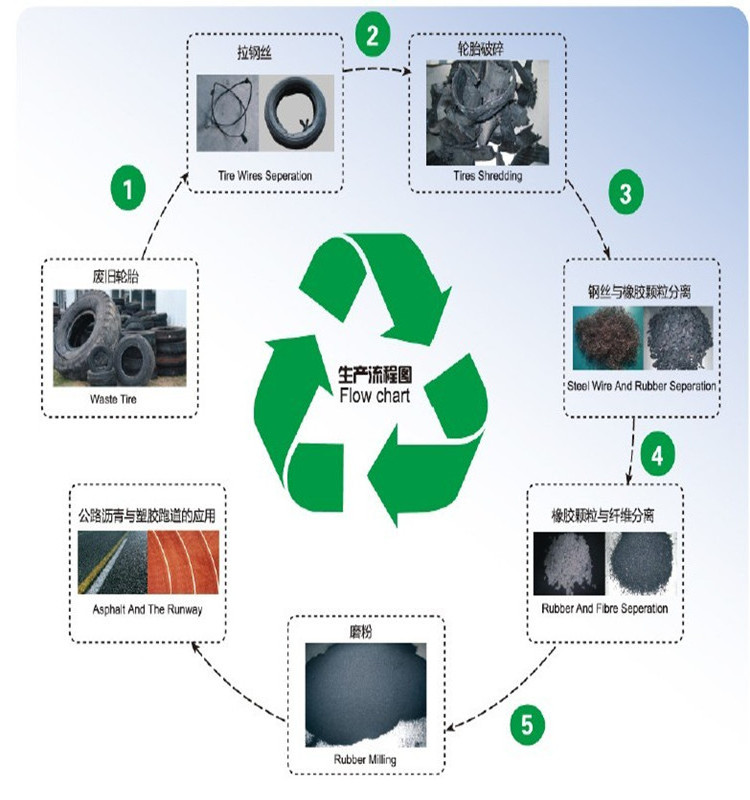

T y re Recycling Process

Optima is experienced in the manufacturing of tyre recycling system. Our tire recycling machines are high effective and work stably.

For our recycling machine,o ur advantages compare to other manufacturers:

1. Blade is easy to maintain and change.

The crusher structure is different with the domestic manufacturer, our upper box body is Arc-shaped which is more suitable for feeding, housing is separated, so it’s easy for blade maintenance;

2. The material and structure of machine is better.

Improved form the previous experience, now the cutter adopts the special alloy steel and heat treatment process is more suitable for cutting copper wire.

3. Vibration screen is customized.

The domestic market are commonly used ordinary screen. There are two disadvantages: 1.fine wire will block screen, 2. During process, it will generate static electricity which will be sticky on mesh, it’s very difficult to clean, these two factors will seriously affect the separation effect.

4. Dust removal system is more effective.

Our equipment dust removal system can separate 90% or more of mica tape, PP film filling material and plastic.