- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2800*6600mm

-

Year:

-

2023

-

Power (kW):

-

25 kW

-

Weight (KG):

-

25000 KG

-

Raw material:

-

Ubran Waste Garbage, pp , pe , ps ,cable ,plastic bags etc.

-

Application:

-

processing waste plastic and tires into oil

-

Certification:

-

CE BV

-

Machine type:

-

Batch type

-

Heating fuel:

-

heavy fuel oil , natural gas , coal

-

output product:

-

plastic/tyre pyrolysis oil , carbon black

-

usage of output product:

-

the oil can be used for burning as heating fuel

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Huayin

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2800*6600mm

-

Year:

-

2023

-

Power (kW):

-

25 kW

-

Weight (KG):

-

25000 KG

-

Raw material:

-

Ubran Waste Garbage, pp , pe , ps ,cable ,plastic bags etc.

-

Application:

-

processing waste plastic and tires into oil

-

Certification:

-

CE BV

-

Machine type:

-

Batch type

-

Heating fuel:

-

heavy fuel oil , natural gas , coal

-

output product:

-

plastic/tyre pyrolysis oil , carbon black

-

usage of output product:

-

the oil can be used for burning as heating fuel

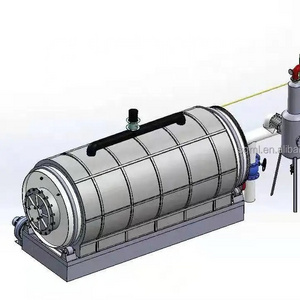

Complete technology processing waste tire and plastic into fuel oil pyrolysis machine

Working process of the plastic waste to oil pyrolysis machine:

1. Firstly, the raw material plastic or tires was put into furnace with auto feeder,then seal the feed inlet system.

2. Secondly, burned the fuel material (coal, or wood, or natural gas, oil ) in the combustion system .The reactor will slowly heat, when the temperature reach around 150 degree Celsius, it will produce oil gas

3.Oil gas will be processed by our technology ,then gone to cooling system to cold liquid oil. The gas which can not be liquid under normal pressure ,which will be designed to back to combustion system to instead the fuel material to burn the reactor .which can save energy very much.

4. After finished oil produce ,the temperature of reactor will be down ,in same time ,carbon black will be discharged automatically.

5. Lastly, when the temperature fall to 100 degree Celsius, worker could opened the door of reactor to discharge of steel wire .

Then can start to another batch working.

Output products from the waste plastic pyrolysis to oil machine:

1.

Fuel Oil (50% to 75%)

The main application of oil products produced by our Waste tyre to fuel oil pyrolysis plant is the fuel oil that is widly used for industrial and commercial purposes. Such as power plant factory,glass factory,cement factory,ceramic fatory. the oil yield of plastic is according to different kinds of plastic.

2.Carbon Black (30%)

The third product of Waste plastic to oil pyrolysis plant is carbon black. The quantity of carbon black is about 30% to 35%. Carbon black can application to electric cable jacketing,black nylon bag,rubber additive

3.Exhaust gas (About 10%)

We get about 10% pyrolytic gases during pyrolysis process. The main component of this gases are methane (CH4), so we can not condense and store this gases. We use this gases to heat the reactor and we can use exceed gases for other heating application

|

Model |

HY-05 |

HY-10 |

HY-15 |

HY-30 |

|

Capacity |

5 t/d |

10 t/d |

15 t/d |

30-35 t/d |

|

Working Type |

Batch |

Batch |

Batch |

Continuous |

|

Reactor size(m) |

D2.2*L5.5 |

D2.8*L6.6 |

D2.8*L8.1 |

D1.2*L24 |

|

Reactor material |

Q245R |

Q245R |

Q245R |

310S stainless steel |

|

Power |

29.4KW |

32KW |

34KW |

100KW |

|

Burners |

3*300,000 kcal |

3*300,000 kcal |

4*300,000 kcal |

12*30000kcal |

|

Landing Area |

200m2 |

300m2 |

350m2 |

700m2 |

|

Number of Containers |

1*40FR+1*40HQ |

1*40FR+2*40HQ |

1*40FR+2*40HQ |

bulk cargo |

|

Cooling Mode |

Circle Water |

Working pressure | Normal |

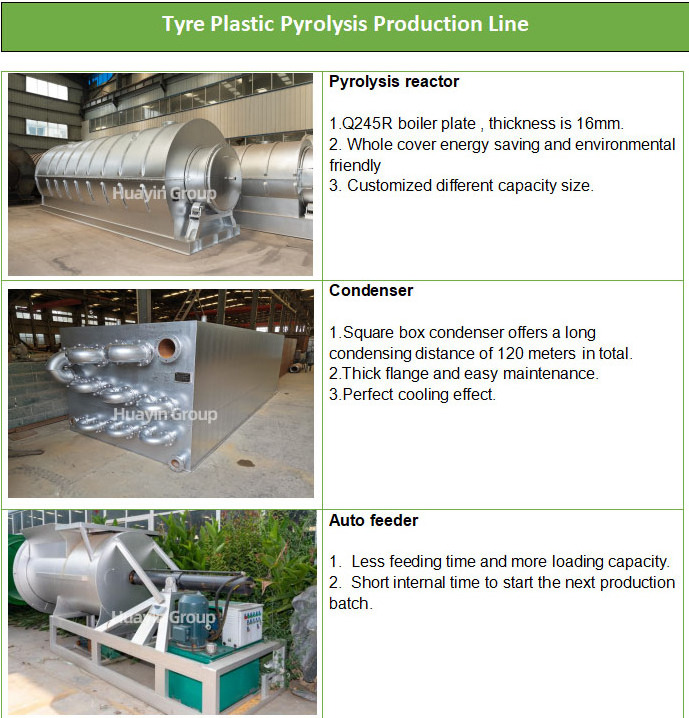

Advantage of our plastic into oil machine

1. Feeding raw material with auto feeder device , the auto feeder is our patent product , it has 60ton hydraulic pressure , so it can push the raw material into the reactor easily.

2. Unique Craft Condensers: High condensing efficiency with more oil output. Good quality oil, longer lifetime, and easy to clean.

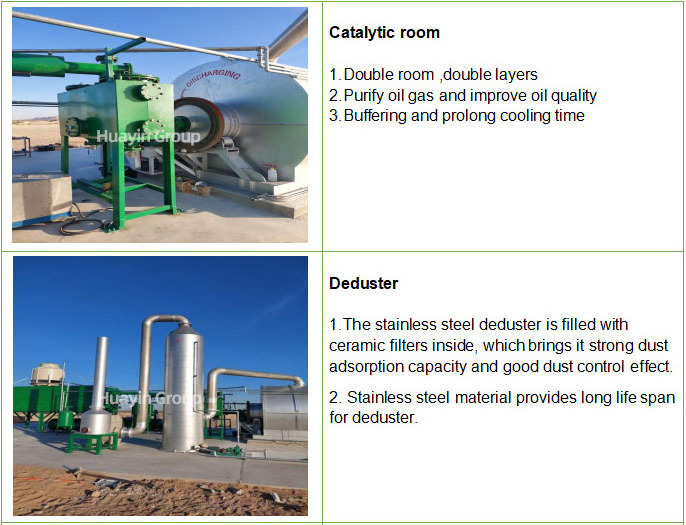

3. Patent Unique dedusting device: More efficient removal of the acid gas and dust of the smoke by neutralization, purification and absorption, environmental friendly without pollution.

4. Patent Carbon Black Discharging System: Speedy fully enclosed Auto-discharging under high temperature, avoiding carbon black pollution, saving time.

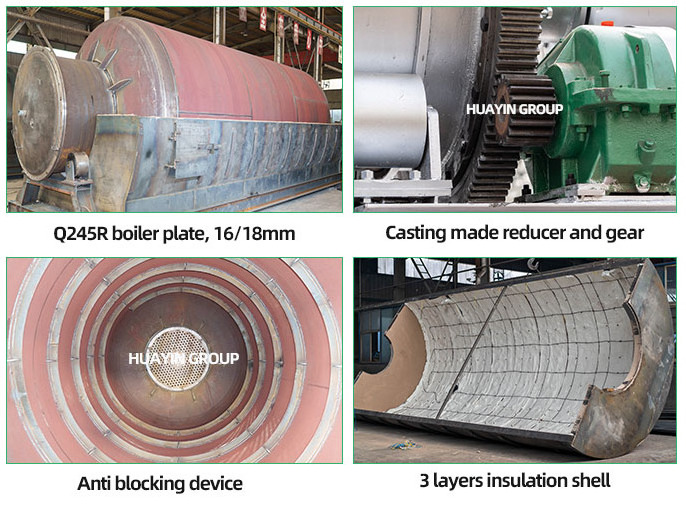

5. Automatic Submerged welding technology, ultrasonic nondestructive testing, both manual and the automatic safety devices.

6. Sync Gas Recycling System: Fully burned after recycling and utilization, saving fuel and preventing pollution.

7. Direct Heating System: Enlarging heating square to lengthen the lifespan of the reactor and easy to control the temperature.

8. National Patent, unique heat insulation shell; high efficiency temperature keeping, excellent energy-saving effect.

Our services

- We will send engineer to guide the installation and training your workers to operate the machine.

- 4-6 workers is needed to operate the plastic pyrolysis oil machine.

- Customers shall prepare the electricity and water .

Usually the delivery time for the plastic to oil pyrolysis machine is 25 working days after received the deposit ,the pyrolysis machine need to be shipped with one 40'FR and two or three 40'HQ

Certificates:

Our company

Xinxiang Huayin Renewable Energy Equipment Co., Ltd is located in Xinxiang City, Henan Province, and is specialized in manufacturing waste tires/plastics to fuel oil pyrolysis machines and waste oil for diesel distillation machines since 1993. We have more than 2000 square meters of running demo plants for customers' visitation and learning. our plants have been exported to over 9 0 countries around the world including Romania, Hungary, Turkey, Slovakia, Ecuador, Guatemala, Haiti, Mexico, Peru, Canada, USA, Jordan, UAE, Lebanon, Kuwait, Italy, Chile, Poland, England, Thailand, Greece, Mexico, Benin, Indonesia, India, Singapore, Russia, etc.

If you are interested in this plastic pyrolysis to oil machine , please feel free to contact with us !

Q: How To Choose A Suitable Tire Pyrolysis Line?

Q: Can You Process Plastic Waste ?

Q: What About The Machine Installation?

Q: How About The Spare Parts?

Q: Will You Test The Machine Before Delivery?

For more details , welcome send us inquiry !