- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

200 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Max. printing Area:

-

90*130mm

-

color:

-

blue

-

specialty:

-

convey

-

After Warranty Service:

-

Video technical support

-

Product name:

-

Pneumatic Pad Printing Machine

-

Printing Colors:

-

1-2 Colors

-

Plate size:

-

100*200mm

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LC

-

Voltage:

-

220V/50HZ

-

Weight:

-

200 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Max. printing Area:

-

90*130mm

-

color:

-

blue

-

specialty:

-

convey

-

After Warranty Service:

-

Video technical support

-

Product name:

-

Pneumatic Pad Printing Machine

-

Printing Colors:

-

1-2 Colors

-

Plate size:

-

100*200mm

| Application: |

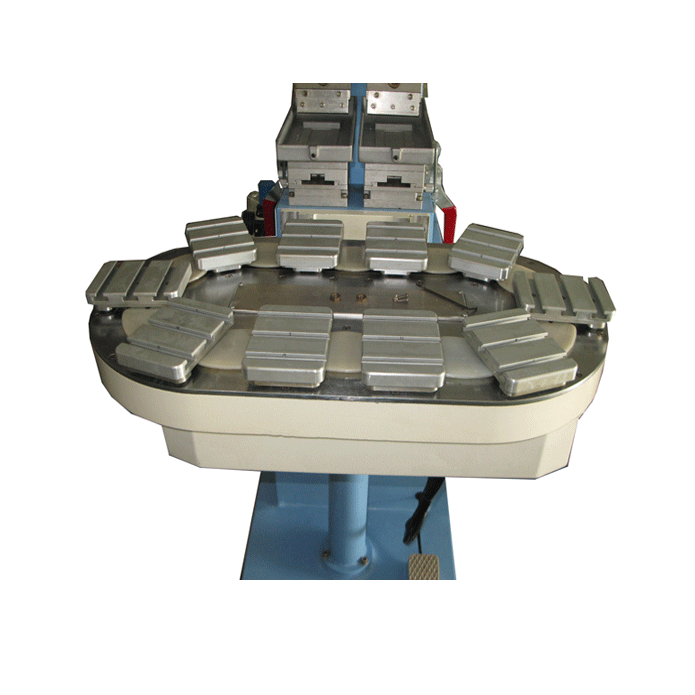

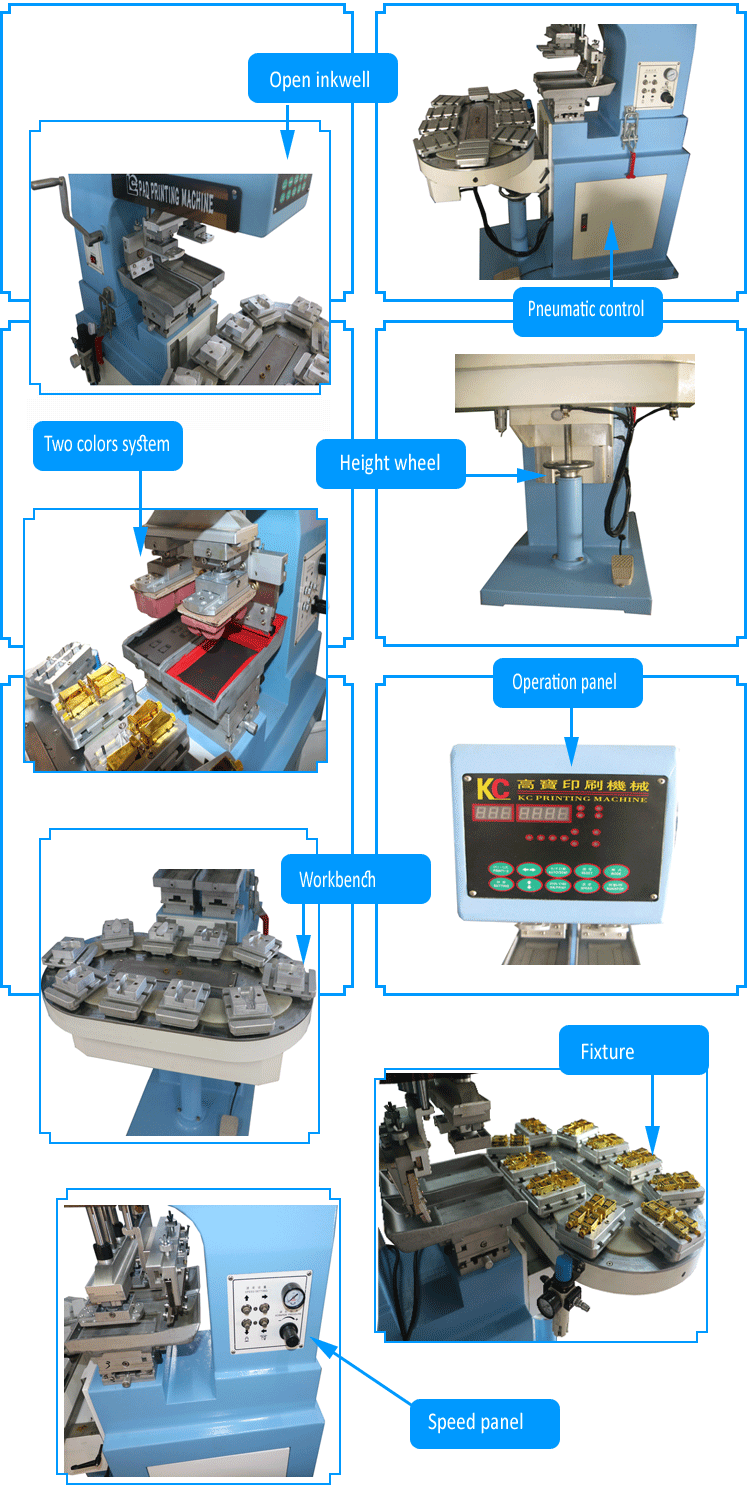

SP2-40610 two colors Open pad printer with conveyer:

Print both one color and two colors with conveyer worktable, Printing speed is more precision. With Ink tray to store ink, Ink adjustment simply; With coin aluminum structure ensure more stabilization and long life. Independent Balance blade Technology Ensure ink removing easily. Make min Pressure to remove ink and prolong the life of steel plate; Can print almost small size objects. so sold very nice in the world. Widely used in the industry field of cosmetics cases, electron parts, Toys, plastics production, Houseware, gifts, decorations. A completely printing solution including ink and thinner, fixtures, steel plates, rubber pads provided when you send us samples to send. Max Plate size: 100*150mm. Conveyer stroke: 125mm. |

| Specifications: |

SP2-40610

1.Max. plate size: 100×150mm; 2.Max. worktable area: 90×130mm; 3.Max. printing Area: 90×130mm; 4.Max Products Dimension: 100×140mm; 5.Max. printing speed: 1200pcs/hr; 6.Printable color quantity:2 7.Air consumption: 166Litre/min(6bar); 8.Station Number: 10. SP2-40810 1.Max. plate size: 100×200mm; 2.Max. worktable area: 90×125mm; 3.Max. printing Area: 90×170mm; 4.Max Products Dimension: 100×140mm; 5.Max. printing speed: 1200pcs/hr; 6.Printable color quantity:2 7.Air consumption: 186Litre/min(6bar); 8.Table Station Number: 10. |

| Advantages: |

1. 2-color,gear-type conveyor with 10 stations;

2. Microprocessor control for each function ; 3. 4-Digit auto counter built-in; 4. Coin aluminum structure ensures sturdiness; 5. Ink roller used for ink applying is easy to remove and clean; 6. Independent stroke and speed adjustment for pad up/down; 7. Auto balanced doctor blade ensures that ink can be scraped cleanly and completely; 8. Adjustable printing speed meets different printing requirements; 9. Ink roller keeps working while pad doesn't lower down ; 10. Pad takes ink twice and prints once to get thicker ink; 11.Independently adjustable ink tray base, easy overprint; 12.Auto air drying available; |

Test case

Machine details

1. What is a pad printer ?

Pad printing machine is the machine, which uses an indirect printing process, it is very suitable for printing irregular surface of small products, make up for the lack of screen printing process, known as the screen printing twin sisters .

2 . The difference between the closed cup pad printer and open inkwell pad printer

The open ink-tray pad printer uses the ink-tray as the ink supply way, the ink is exposed to the air, the VOC is easy to volatilize to cause the air pollution, the ink-tray pad printers sells mainly to China, Asia, Africa and Eastern Europe and so on the environmental pollution request is not Too high a country;

The closed cup pad printer uses the closed cup as the ink supply way, the ink is enclosed in the cup, the VOC can not volatilize to the air, does not have the pollution to the environment basically, the closed cup pad printers sells mainly to Western Europe, On the environment demanding countries and regions.

3. Shuttle pad printer and Turntable pad printer

Shuttle pad printer is installed shuttle table printing machine, printing back and forth between the colors in the printing, shuttle printing machine can only print one product at a time, more accurate overprint, slower; and Turntable pad printer is installed Rotary table of the printing machine, a 10-station, 16-station, 22-station in various forms. Turntable pad printing machine stations are required to install the same product for printing, faster, no printing shuttle printing machine accurate.

4. Pad printing machine operating system

The ordinary printing machine adopts the microcomputer control system to carry on the control, the high-end pad printing machine uses the PLC to carry on the control, specially the servo control system pad printing machine or the automatic pad printing machine, uses the PLC control system quite commonly.

5. Pad printing machine movement characteristics

Most of the pad printing machine pneumatic control, slower, low cost. With the printing quality and printing speed of the user's high demand in recent years, the use of mechanical control of the pad printing machine more and more common. Pad printing machine automation is the most distinctive trend, the use of automatic feeding system, prepress processing device, servo drive system, automatic printing, drying machine as one of the mechanical and pneumatic motion perfect combination, greatly improving the productivity.

6. How to evaluate the quality of the pad printer

Pad Printing machine technology content is low, more and more enterprises began to produce and sell pad printing machines, pad printing machines of uneven quality, how to evaluate the quality of pad printing machine is essential. As the majority of brand-name pad printing machine is not sold through the network, so, through Alibaba sales of pad printing machines are low-end pad printing machine.

1) Design of the factory means: a special design department of the enterprise quality is more reliable. China has 70% of the pad printing machine manufacturing enterprises and no special design department, the development of new products on-site assembly by the basic, which is extremely adverse to the standardization of production machinery;

2) Processing means: CNC processing costs are higher, but the parts manufactured high precision; visit the factory must inspect whether the factory has CNC machining capacity;

3) Materials Selection: Material selection is very important. Now fierce competition, the vast majority of domestic factories in the selection of the above efforts, only the brand enterprises are willing to insist on the selection criteria above;

7. What is pad plate of pad printer?

8. How to make rubber pad of pad printer?

9. What is fixture of pad printer?

10.How to judge number color of pad printer?

11. How to choose pad printing ink?