- Product Details

- {{item.text}}

Quick Details

-

Weight of falling parts(kg):

-

3400

-

Max hit number(min-1):

-

85

-

Hit stroke(mm):

-

740

-

Working oil pressure(Mpa):

-

20

-

Main motor power(KW):

-

2*55

-

Machine weight(kg):

-

78500

-

Usage:

-

for closed die forgings

Quick Details

-

Place of Origin:

-

Henan, China

-

Name:

-

CNC Hydraulic Double Acting Drop Closed Die Forging Hammer

-

Hit energy(KJ):

-

50

-

Weight of falling parts(kg):

-

3400

-

Max hit number(min-1):

-

85

-

Hit stroke(mm):

-

740

-

Working oil pressure(Mpa):

-

20

-

Main motor power(KW):

-

2*55

-

Machine weight(kg):

-

78500

-

Usage:

-

for closed die forgings

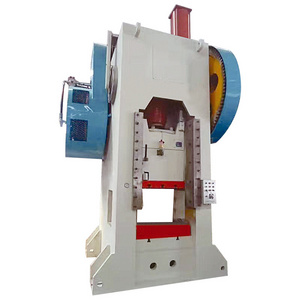

CNC Hydraulic Double Acting Drop Closed Die Forging Hammer.

CNC Hydraulic Double Acting Drop Closed Die Forging Hammer

is program-controlled hydraulic die forging hammer, they are widely applied in automobile forgings, motorcycle forgings, hardware forgings, hand tools blank forgings, stainless steel tableware, and aeronautic forgings etc, especially for the precision forging field.

1. Hit energy can be controlled accurately.

Hit energy can be controlled at ±1.5%. After testing 4 copper columns, deviation in height is ≤0.3mm. after change forging dies, input the die height, the system can automatically adjust parameters to assure energy’s identity and accuracy.

2. Hit procedure can be controlled by digitization.

PLC can save dozens of forging program, also can load them conveniently, save the program ready time.

3. X” shape guide, the guide ability is good.

CNC forging hammer use "X" shape guide design, can enhance the unbalance loading ablity and the guide gap is less than 0.2 mm.

4. Material using rate is high.

The forging forged on CNC forging hammer, flash is thin and small.

5. Low noisy and vibration.

CNC forging hammer adopting spring &damping device can decrease 90% vibration.

6. Automatic lubrication device.

The cnc forging hammer lubrication time controlled by PLC, reduce maintain labore and prolong the guide surface working life.

7. CNC forging hammer match forging robot can build automatic forging line.

CNC Hydraulic Double Acting Drop Closed Die Forging Hammer body frame

Name: CNC fully hydraulic die forging hammer

Brand: Anyang

Original: China

CNC fully hydraulic die forging hammer use "X" shape guide design, can enhance the unbalance loading ability and the guide gap is less than 0.2 mm.

Main Features

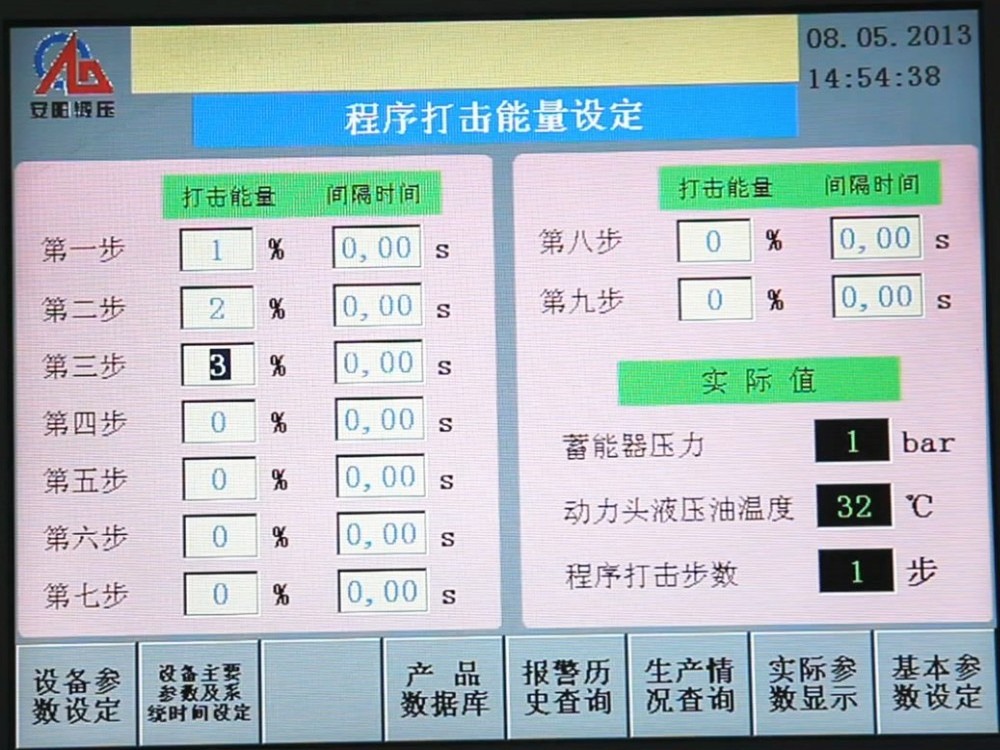

Name:

Touch screen

Brand: Anyang

Original: China

Hit energy can be controlled at ±1.5% though touch screen. After testing 4 copper columns, deviation in height is ≤0.3mm. after change forging dies, input the die height, the system can automatically adjust parameters to assure energy’s identity and accuracy.

CNC Hydraulic Double Acting Drop Closed Die Forging Hammer spring &damping

Name:

spring &damping

Brand:

Anyang

Original:

China

CNC fully hydraulic die forging hammer adopting spring &damping device can decrease 90% vibration.

High precision forgings

CNC fully hydraulic die forging hammer ,which body is adopted "U"type whole piece castings,large rifidity,coupled with special "X"type guild rail,which ensures the space between tup and guild rail controlled within 0.2mm.

Anyang forging press have 4 sets of big CNC vertical boring-milling machine to process CNC forging hammer frame casting, and have 6 sets of CNC machining center to machine cnc forging hammer valve holder, ram, sow block etc key parts. also have over 200 sets of cnc lathers to produce other parts for cnc forging hammer.

Anyang forging press have over 10000 square meter work shop to assembly the CNC closed die forging hammers, the prodcing ability over 100 sets per year.

Anyang forging press have over 200 sets of different CNC lathers to machine CNC closed die forging hammer hammer parts.

Anyang forging press quality control team have over 30 engineers to inspect all the CNC forging hammer parts is 100% perfect.

Our CNC Hydraulic Double Acting Drop Closed Die Forging Hammer have got CE, design patent, famous brand etc certifications.

Anyang CNC Hydraulic Double Acting Drop Closed Die Forging Hammer cost performance is very high, so it's very popular in the precise closed die forging field, and exported to USA, Germany, Japan, Tailand, India, Vietnam etc over 30 countries.