The machine uses high quality steel welding to eliminate stress treatment,overall machining,to confirm the machine stability in a

longtime.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

JL PARTEXP

-

Voltage:

-

380V/415V/220V

-

Power (kW):

-

35

-

Weight (T):

-

7

-

Speed:

-

330*330~500*500

-

Knife material:

-

9CrSi

-

Knife thickness:

-

15mm - 60mm or customized

-

Shaft material:

-

45#Steel

Quick Details

-

Max.Production Capacity (kg/h):

-

2000

-

Place of Origin:

-

Anhui, China

-

Production Capacity (kg/h):

-

100 - 1000 kg/h

-

Brand Name:

-

JL PARTEXP

-

Voltage:

-

380V/415V/220V

-

Power (kW):

-

35

-

Weight (T):

-

7

-

Speed:

-

330*330~500*500

-

Knife material:

-

9CrSi

-

Knife thickness:

-

15mm - 60mm or customized

-

Shaft material:

-

45#Steel

Performance and Features

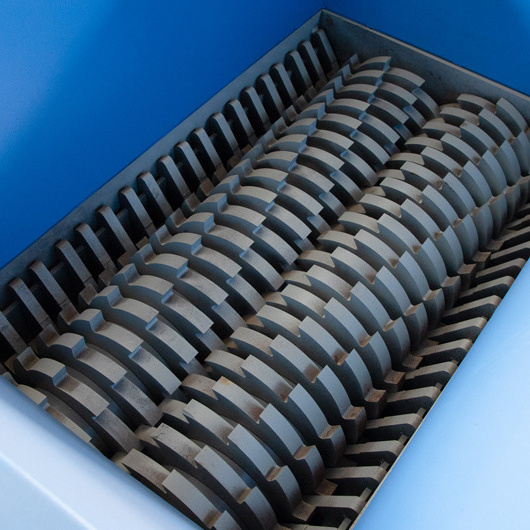

Double shaft shredder is used to shredding plastic, rubber, fiber, paper, wood,large hollowproducts ( plastic bucket etc), and all kinds of waste products especially the metal, or other waste products .like roll film, woven bag, tv, refrigerator shell, wood,car and tires .hollow barrels,Fishing net, cardboard, circuit board , etc.

Blades thickness and claw quantity can be changed according to different products. Shred the hollow products can be equipped with pressure device to increase production , and add the rotary to control the discharge size.

Blades thickness and claw quantity can be changed according to different products. Shred the hollow products can be equipped with pressure device to increase production , and add the rotary to control the discharge size.

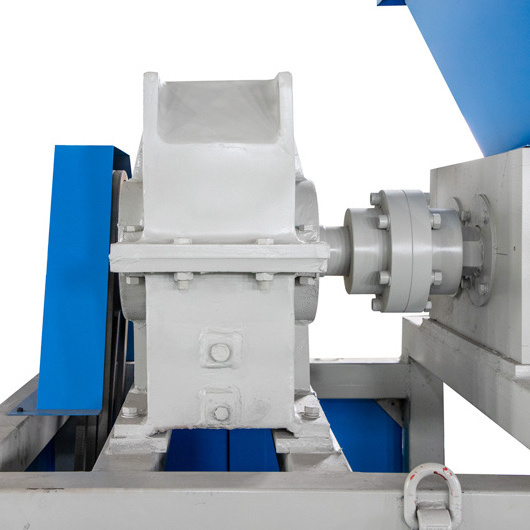

Main body of the shredder

Rotary Kinfe / Fixed Knife

Rotary knife uses special alloy steel,forging blank, precision machining, heat treatment and multiple freezing heat treatment

technology,the toughness and hardness can be can be used repeatedly to confirm cutting performance and service life.The fixed

knife the patent hook type installation,optimize the tool replacement function,make the blades maintenance and replacement more

efficient.

Use the high strengh and heavy special steel,to provide a powerful driving force for cutting.

technology,the toughness and hardness can be can be used repeatedly to confirm cutting performance and service life.The fixed

knife the patent hook type installation,optimize the tool replacement function,make the blades maintenance and replacement more

efficient.

Use the high strengh and heavy special steel,to provide a powerful driving force for cutting.

Bearing And Seal

The bearing seat adopts detachable combination, can quickly remove the rotary knife, fixed knife, bearings and other parts, easy to maintain and replace the blades.The special sealing structure can effectively prevent the contact between the broken material and grease,shred liquid products can also protect the bearings and gears.

Blades And Shafts

Pure copper coil, high strength. High -precision rotor, intelligent precision processing, dynamic balance debugging, running smoothly.

Cold -rolled steel sheets have good ductility, compressiveness and abrasion resistance, low noise operation of the whole machine, strong power, stable work.

Multiple protection system

The shredding system has multiple protections for machinery and electrical appliances. It is equipped with main motor start protection, automatic feeding overload, motor card overload, automatic reverse and re-distribution of materials to be shredded

(adjustable reverse times).

(adjustable reverse times).

Noise reduction and dust reduction measures are taken into consideration in the design project, and the external noise and dust are reduced as much as possible. The noise of the equipment operating point is ≤85(DB)A.

|

Main Technical Parameters

|

|

|

|

|

|

|||||

|

model

|

Cutting chamber

|

Blade diameter

|

Blade thickness

|

Number of blades

|

motor

|

|||||

|

JL-500

|

500*500mm

|

250mm

|

20mm

|

25pcs

|

7.5KW+7.5KW

|

|||||

|

JL-600

|

600*400mm

|

200mm

|

20mm

|

30pcs

|

11KW+11KW

|

|||||

|

JL-800

|

800*600mm

|

300mm

|

20mm

|

40pcs

|

18.5KW+18.5KW

|

|||||

|

JL-1000

|

1000*600mm

|

300mm

|

20mm

|

50pcs

|

22KW+22KW

|

|||||

|

JL-1200

|

1200*600mm

|

300mm

|

30mm

|

40pcs

|

30KW+30KW

|

|||||

|

JL-1200

|

1200*800mm

|

400mm

|

50mm

|

24pcs

|

30KW+30KW

|

|||||

|

JL-1600

|

1600*1000mm

|

500mm

|

50mm

|

32pcs

|

45KW+45KW

|

|||||

|

JL-1800

|

1800*1200mm

|

600mm

|

60mm

|

30pcs

|

55KW+55KW

|

|||||

|

|

|

|

|

|

||||||

Structural Features

1. Shredder main body:

The machine uses high quality steel welding to eliminate stress treatment,overall machining,to confirm the

machine stability in a long time.

2. Rotary kinfe / Fixed knife: Rotary knife uses special alloy steel,forging blank, precision machining, heat treatment and

multiple freezing heat treatment technology,the toughness and hardness can be can be used repeatedly to confirm cutting

performance and service life.The fixed knife the patent hook type installation,optimize the tool replacement function,make the

blades maintenance and replacement more efficient.

3.Bearing And Seal: The bearing seat adopts detachable combination, can quickly remove the rotary knife, fixed knife, bearings and

other parts,easy to maintain and replace the bladesihe special sealing structure can effectively prevent the contact between the

broken material and grease,shred liquid products can also protect the bearings and gears.

4.Shafts: Use the high strengh and heavy special steel,to provide a powerful driving force for cutting.

Blade Selection

1.Whole Blade Structure

Suitable for shredding various products, such as electronic garbage, hard plastic, rubber, packing barrels of various materials,etc.

2.Assembly Knife Structure

Suitable for shredding heavy metal or plastic, such as refrigerator, metal barrel and material with thickness of more than 10mm.

3.SW Type Blade Structure

Suitable for shredding general products,such as wood,aluminum engine housings or brittle materials.

4.VZ Type Blade Structure

Suitable for shredding products, such as packaged aluminum,car shell, etc.

5.Pineapple Type Blade Structure

Suitable for shredding circuit boards and other hard plastic,can shred the product 10mm or less.

6.SPR Type Blade Structure

Suitable for shredding RDF,MSW, and other living waste products.

Suitable for shredding various products, such as electronic garbage, hard plastic, rubber, packing barrels of various materials,etc.

2.Assembly Knife Structure

Suitable for shredding heavy metal or plastic, such as refrigerator, metal barrel and material with thickness of more than 10mm.

3.SW Type Blade Structure

Suitable for shredding general products,such as wood,aluminum engine housings or brittle materials.

4.VZ Type Blade Structure

Suitable for shredding products, such as packaged aluminum,car shell, etc.

5.Pineapple Type Blade Structure

Suitable for shredding circuit boards and other hard plastic,can shred the product 10mm or less.

6.SPR Type Blade Structure

Suitable for shredding RDF,MSW, and other living waste products.

Product introduction

Double shaft shredder blades,can be divided into three claw shredder blades, eight claw shredder blades, twelve claw shredder blade,used for crushing, tearing and extruding and reducing the size of materials.Double shaft shredder blade is widely used in

plastic waste, waste rubber, wood and other large waste products.

The specifications: type 300, type 350, type 400, type 450, type 500 and type 600.

plastic waste, waste rubber, wood and other large waste products.

The specifications: type 300, type 350, type 400, type 450, type 500 and type 600.

It can crush a variety of waste materials such as: straw, wood, logs, coconut shells, cardboard, rubber tires, metal, automobiles,bicycles, bumpers, hard drives, mobile phones, computers, circuit boards, chips, copper pipes, cables, aluminum products, Cans,paint buckets, milk cans, PP/PVC/PE/ABS plastics, plastic bottles, plastic boxes, plastic bags,plastic films, foam, latex, animal bones, animal carcasses, compost, etc.,

Factory Introduction

We are a collection of scientific and technological research and production company,specialize in shredder machine ,import and export business the professional manufacturer .Our main products:shredder machine,Double shaft shredder kitchen waste shredder,small shredder,metal shredder,rubber and tire shredder,plastic shredder,wood shredder,cans shredder,cars shredder,woven bag shredder,film shredder,crusher etc. Our company has a professional technical team of engineers for shredder machine research and design, machining, assembling, repairing.We always insist the principle of "Quality First,Reputation first" to provide best service .We ask for "Pragmatic and honest", to be a responsible company. We hope to establish a long term relationship with you.We sincerely hope we can build good future,hand in hand.

More local services

Don't worry!

We have two offices in China and Dubai to provide you with high-quality pre-sales and after-sales service.

We have two offices in China and Dubai to provide you with high-quality pre-sales and after-sales service.

Hot Searches