- Product Details

- {{item.text}}

Quick Details

Quick Details

-

Place of Origin:

-

Henan, China

-

After-sales Service Provided:

-

Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support, Engineers available to service machinery overseas

-

Application:

-

harvester and baler

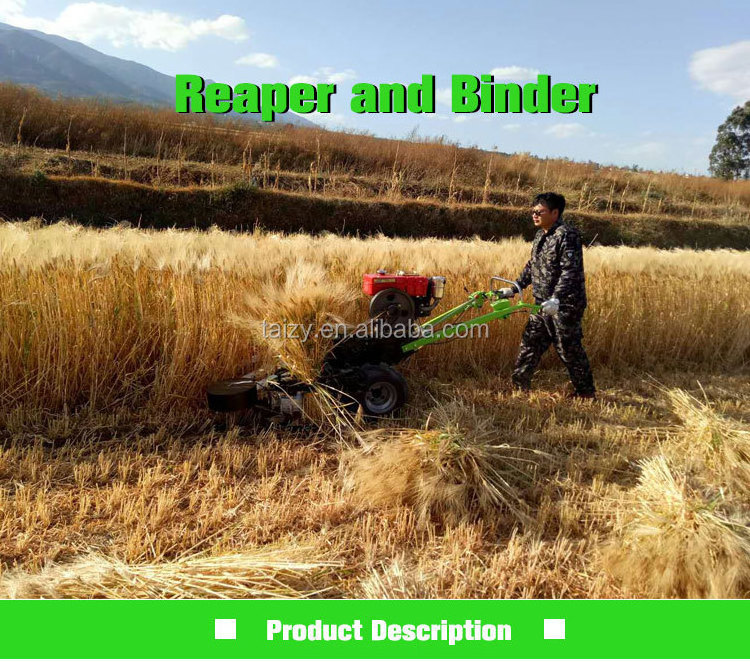

high efficiency mini rice harvester reaper binder for farm use

Brief introduction:

With more than 10 years’ experience in manufacturing the reaper binder and high reputation from our customers around the world, we supply the excellent reaper binder to cut and bundle the low stem crops like wheat, rice, barley and oats, etc. grown in small fields, plains, hills, slopes and mountain areas.

Technical parameter

|

Model |

4GK90 Reaper binder |

|

Cutting Width(mm) |

900 |

|

Mini Cutting Height(mm) |

≥50 |

|

Placing Type |

Side direction & banded placed |

|

Productivity(m2/h) |

1300-2000 |

|

Matched Power |

8hp water cooling diesel engine |

|

Net Weight(kg) |

262 |

|

Gross Weight(kg) |

302 |

|

Packing Size(L*W*H) |

1.4*1.4*0.8m |

|

20 GP |

16 sets |

|

40GP |

34 sets |

Work principle:

Reaper binder mainly consists of engine, stalks conveying device, power transmission system, walk device, cutting unit and binding unit. When the reaper binder works, first the stalks are separated by divider and cut off by cutter. Then under the help of conveying chain and spring guide, the cut stalks are transported to the binding device. After binding into bundles, the bundles will be released and thrown on the right of moving direction, thus finishing the reaping and binding process.

Advantages:

1. Cutting and binding completed at the same time, reducing heavy manual work and working time.

2. Adjustable handle: Up and down 90°, around 360°. More flexible adapt to different environment.

3. Height of stubble and bundling size can be adjusted.

4. Equipped with differential turning system, flexible to operate.

5. Low stubble height is convenient for the future management of fields.

6. Compact structure, light weight and reliable performance make it easy to control.

7. Shaft drive system guarantees stable and safe work.

Maintenace:

1. Clean the residual weeds and dirt;

2. Check if the fastening piece and connecting piece loosen;

3. Add lube timely in the engine, bundling device;

4. Check if the control parts flexible and reliable.

1. over 10 years eperience.

2. ISO international certificate

3. winning great popularity.

4. one year warranty.

5. fast, timely delivery & reliable after-sales service.

6. spare parts & tools delivered with harvester for daily maintenance.

7. customers & quality first