- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

None

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

GUOHUA

-

Model Number:

-

CYW-T607

-

Product Name:

-

Polyurethane cement injection grouting Waterproof Coating

-

Leveling:

-

20min,without obvious marks

-

Low temperature flexibility:

-

-35℃,No crack

-

Certificates:

-

ISO9001-2008

-

Weight:

-

7kg/barrel

-

Solids content /%:

-

92

-

Surface drying time /h:

-

12

-

Fully drying time/h:

-

24

-

Tensile strength/mpa:

-

12.0

-

Elongation at break /%:

-

450

Quick Details

-

CAS No.:

-

None

-

Other Names:

-

Waterproof coating

-

MF:

-

None

-

EINECS No.:

-

None

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

GUOHUA

-

Model Number:

-

CYW-T607

-

Product Name:

-

Polyurethane cement injection grouting Waterproof Coating

-

Leveling:

-

20min,without obvious marks

-

Low temperature flexibility:

-

-35℃,No crack

-

Certificates:

-

ISO9001-2008

-

Weight:

-

7kg/barrel

-

Solids content /%:

-

92

-

Surface drying time /h:

-

12

-

Fully drying time/h:

-

24

-

Tensile strength/mpa:

-

12.0

-

Elongation at break /%:

-

450

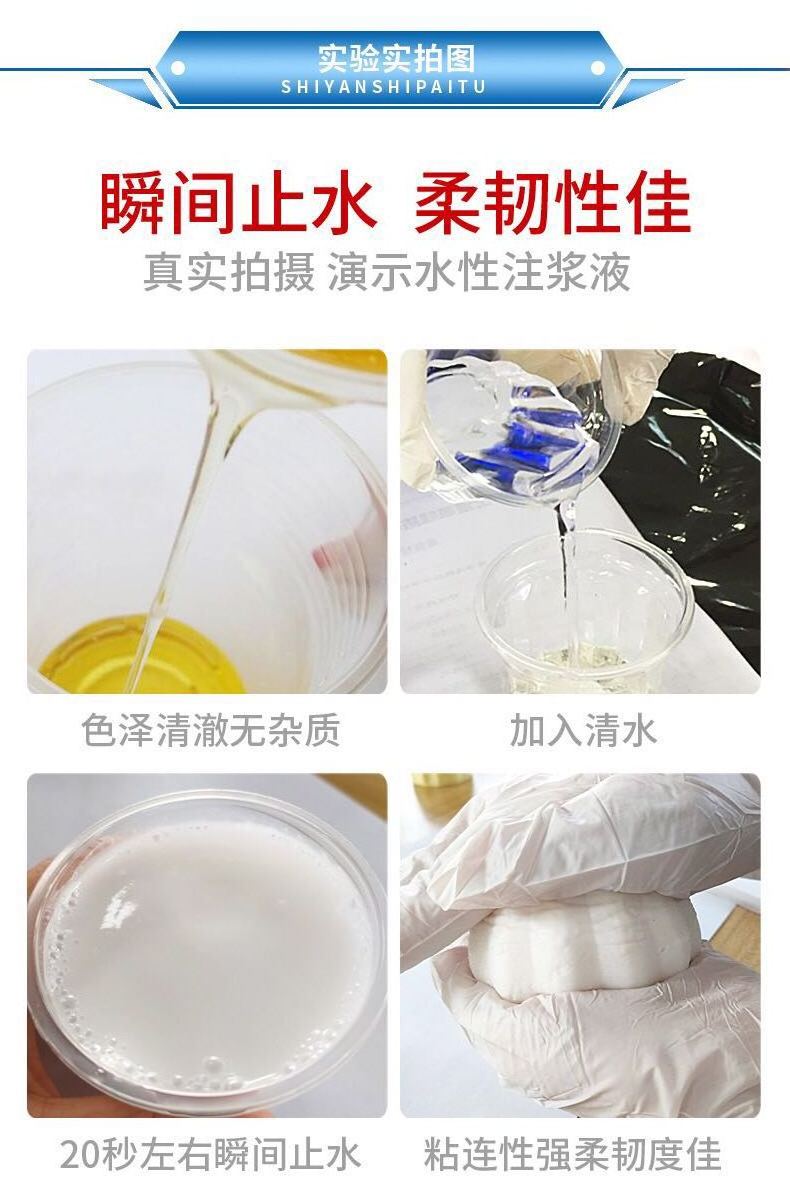

Polyurethane cement injection grouting Waterproof Coating

Features of product:

1.The time of drying and curing is two times as fast as general single-part PU waterproofing coating, which could greatly

shorten the construction stage.

2.Because of the more scientific and precise control of dynamic viscosity, little deposit is produced so that substantially reducing the waste of coating deposit.

3.Good function of physical mechanics, its tensile strength, extension rate, etc all far superior to GB standard of type one and two.

4.Almost no smell, especially suitable for poor ventilation environment

5.Various performance indicators are very good, but its price is moderate compared with the domestic similar products.

So its performance-to-price ratio is high.

Polyurethane cement injection grouting Waterproof Coating

Base Course Requirement:

The base course should be clean, solid, smooth, no dust, grease and water.

Construction:

1.Coating construction is generally 3~4 times, scraping and coating on the base course evenly with a rubber scraper or

bristle brush after stirring. The first time coating film should be thin in order to prevent bubbling.

2.The construction protect layer must be done upon coating thickness had met the design requirement and gained

acceptance.

3.Coating can be carrying on as soon as the prior film is non-stick.

4.In order to cohering the waterproof layer and other materials, you can add some coarse sand before the last coating

becoming non-sticky under facade construction.

5.The direction of the prior and the next coating should be vertical and repeated for many times to make sure that the

coating is completely saturating and cohering the base course. The second time coating can be carrying on as soon as the prior film is non-stick.

6.In order to cohering the waterproof layer and other materials, you can add some coarse sand before the last coating

becoming non-sticky under facade construction.

7.The construction protect layer must be done upon coating thickness had met the design requirement and gained

acceptance.

1,Q:Are you a factory or trading company?

A:We are a factory

2,Q:Where is your factory located?How can i visit there?

A:Our factory is located in ShijiazhuangCity,Hebei Province,China,about 2 hours plane from Beijing ,Guangzhou ect.We can pick you up at the airport.All our clients,from home or abroad,are warmly

welcome to visit us!

3,Q:How can i get some samples?

A:We are honored to offer you Free samples.

4:Q:How does your factory do regarding quality control?

A:Quality is priority.King Waterproof Material people always attach great importance to quality controlling from the every

beginning to the very end.Our factory has gain ISO9001:2008,ISO4001:2000 and CEC.