- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

≤0.1%

-

Voltage:

-

380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sunswell

-

Dimension(L*W*H):

-

6750*4835*2700mm

-

Weight:

-

9500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Filling bottle volume:

-

500ml,750ml, 3L etc

-

carbonated beverage filling machine::

-

rinser,filler,capper

-

Processing Type:

-

Draft Beer

-

Processing Types:

-

Carbonated Beverage

-

Power(W):

-

9.2KW

Quick Details

-

Machinery Capacity:

-

12000BPH, 6000BPH, 20000BPH, 16000BPH

-

Packaging Material:

-

Wood

-

Filling Material:

-

Beer, Milk, Water, Juice

-

Filling Accuracy:

-

≤0.1%

-

Voltage:

-

380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sunswell

-

Dimension(L*W*H):

-

6750*4835*2700mm

-

Weight:

-

9500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Filling bottle volume:

-

500ml,750ml, 3L etc

-

carbonated beverage filling machine::

-

rinser,filler,capper

-

Processing Type:

-

Draft Beer

-

Processing Types:

-

Carbonated Beverage

-

Power(W):

-

9.2KW

We can customize liquid food production lines according to customers' demand. Every customer is the result of our proven experience and innovation. We continually focus on providing customers with advanced technology, engineering and facility that are designed with one motto in mind: ensure you to reach business goals with most optimized planning.

\

\

1. Flow chart of canning production line

Empty can depalletizer-----Washer-----Filler seamer-----Inverter------Date printer

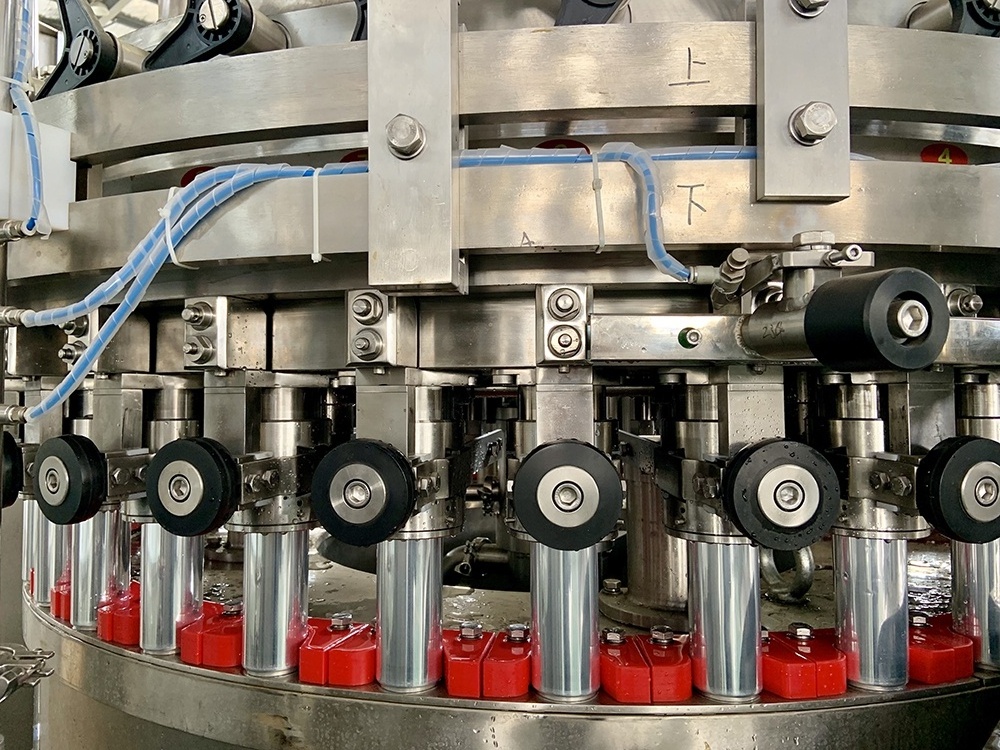

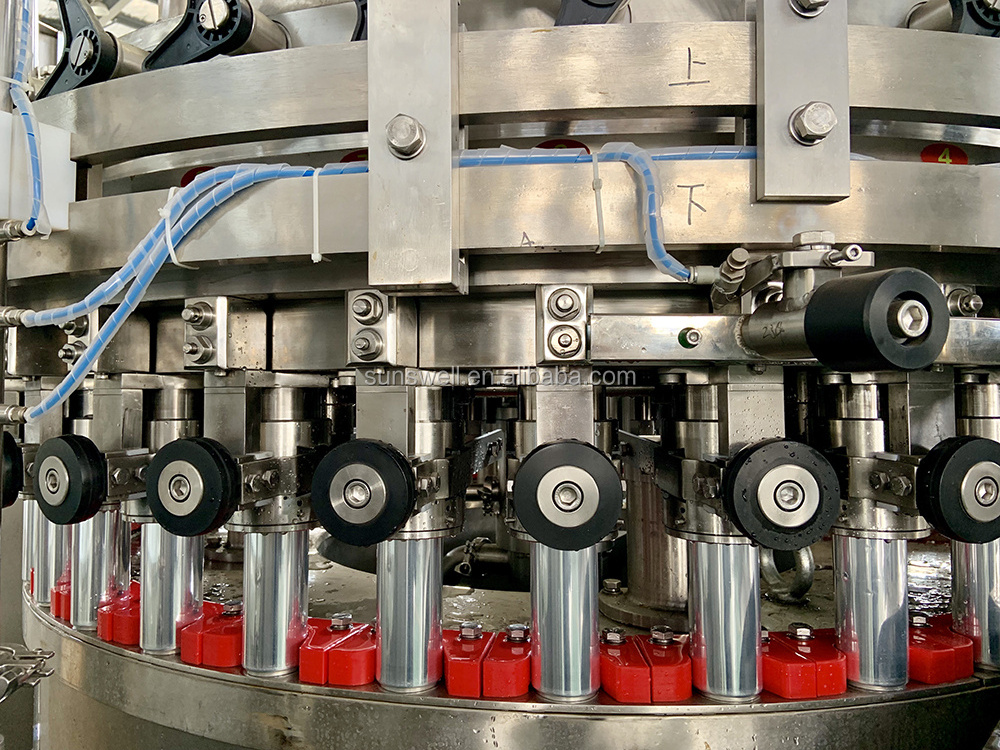

Main components of the can filling line are rinsing, filling, seaming monoblock, tunnel sterilizing machine and conveying system. The key machine is the seamer, which synchronizes with filling machine. The liquid level is stable and the oxygen content is decreased. Through a few simple adjustments, it could handle different cans. The special structure sealing roller could be adjusted according to can's size.

As the can is easy to get deformed, soft treatment is needed in the transferring process. The conveying system regulates the transferring speed according to the each machine's working condition to assure no can falling or crashing occurs.

Application: soda water, juice, tea, energy drinks,beer, carbonated drinks, etc.

Filling system: gravity or isobaric filling

Suitable: aluminum can, pop can, PET can

Filling and sealing is the overall designed,power system by filling sealing system to ensure that both the absolute synchronization and coordination.

This machinery adopts the advanced machine,electrical equipment,and pneumatic control technology.

This machinery has the characteristics of filling reposefully,high speed,liquid level control,capping reliably.

2. Seamer

Can sealing machine mainly consists of the upper part of the machine, the lower part of the machine, under the cover device, motor drive, hydraulic system and other components.

This model type of sealing machine with a filling machine drive, The can s coming out from the can outfeed dial wheel of the filling machine are in fed in a free order at the beginning and through a period of chain accelerat ion to make the tank reach the correct pitch feed tank s ide belts, in order to prevent the overflow of the liquid in the tank, the tank must have a certain range of adjustment for the delivery of the dial on the side belt of the tank. When each can passes through the canister to detect the proximity switch, the proximity switch is actuated. At this time, the cylinder (makes the lid cutter on the lid retract, a can lid is removed from the lid stack, and is carried by the lid transfer turret u nder the capping head, before the cap can reach the capping device together with the cap, the cap can be accurately positioned through the cap transfer and the sealing star wheel swivel, and then when the cap arrives, the c ap supporting platform accurately lifts the can to the cap’s position.

At this moment , the lid is pushed by the lid to press the lid onto the top of the tank. When the can is clamp ed between the tray can holder and the capping head, the lids start to rotate together, and the capping operation begins. Two flanging rollers complete the crimping.

3. Machine Main features

1) Wholly sealed widow structure which is beautiful, concise, easy and highly operated;

2) Cycling tank design with precision polishing inside;

3) High precision and large flow rate filling valves to meet productive requirement;

4) Specially designed roller structure which is easy to be adjusted, locked and ensure sealing function;

5) Friendly and convenient operating panel with high expansibility.

6) The filling valve is adopts high precision mechanism valve, fast speed filling, high precision liquid level.

7) The filling vat adopts SUS304 material designed sealing vat, to achieve constant pressure filling.

8) The flow rate of the filling valve>125ml/s.

9) Main transmission adopts toothed belt and gearbox open-type transmission assemblies, high efficiency, low noise.

10) The main drive adopts step-less speed change for frequency conversion, the whole machine adopts PLC control; the capping machine and filling machine adopt coupling joint, to ensure synchronization of two machines.

11) With filling with can, no filling without can.

12) The filling manner is constant pressure filling, with fast filling speed and stable action.

13) Adopting introduce into full set of Switzerland (Ferrum) capping technology.

14) Capping trolley adopts high hardness alloy steel quench(HRC> 62), capping curve adopts projection grinder precision machining, to ensure the quality of capping.

15) With capping with can, no capping without can control system, to ensure the normal running of the machine.

16) With CIP automatic rinsing function.

17) With centralized lubrication system.

| YDGF18-4 | YDGF20-4 | YDGF30-6 | YDGF40-6 | YDGF60-6 | YDGF 80-6 |

| 9000CPH | 12000CPH | 18000CPH | 24000CPH | 36000CPH | 48000CPH |

4. FAQ

Q1: which city are you in? how can I get to your factory? Are you a trading company or factory?

A1: We are in Zhangjiagang city, two hours driving from Shanghai. We are factory. Manufacturing mainly beverage filling and packagingmachines. We offer turnkey solutions with more than 10 years experience.

Q2: Why is your prices higher than others?

A2: We offer high-end machines in our business. Welcome to our factory to have a visit. And you will see the difference.

Q3: What is your delivery time?

A3: Normally 30-60 working days depends one machines, water machines are faster, carbonated drink machines are slower.

Q4: How to install my machines when it arrives? How much the cost?

A4: We will send our engineers to your factory to install the machines and train your staff how to operate the machines If needed. Or you can arrange engineers to study in our factory.

You are responsible for air tickets, accommodation and our engineer wage USD100/day/person.

Q5: How long time for installation?

A5: Subject to machines and the situation in your factory. If everything is ready, it will take about 10 days to 25 days.

Q6: How about the spare parts?

A6: We will send one year enough easy broken spare parts together with the machines for free, we suggest you buy more units to save international courier such as DHL, it is really costly.

Q7: What is your guarantee?

A7: We have one year guarantee and life-long technical support. Our service also including machine maintence.

Q8: What is your payment term?

A8: 30%T/T in advance as down payment, rest should be paid before shipping. L/C is supported also.