- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

PPM-C400BS

-

Product name:

-

SMT Pick and Place Machine

-

Mounting Precision:

-

0.025mm

-

Visual Mounting Speed:

-

8000 pcs/h

-

Feeder Type:

-

Yamaha CL Feeder,Electric Feeder

-

PCB Minimal Size:

-

45*45mm

-

PCB Maximum Size:

-

500*400mm

-

Number of Feeder:

-

64 Level

-

Motor:

-

Servo Motor

-

Outline Size:

-

1335*1200*1390mm

Quick Details

-

Weight (KG):

-

440

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

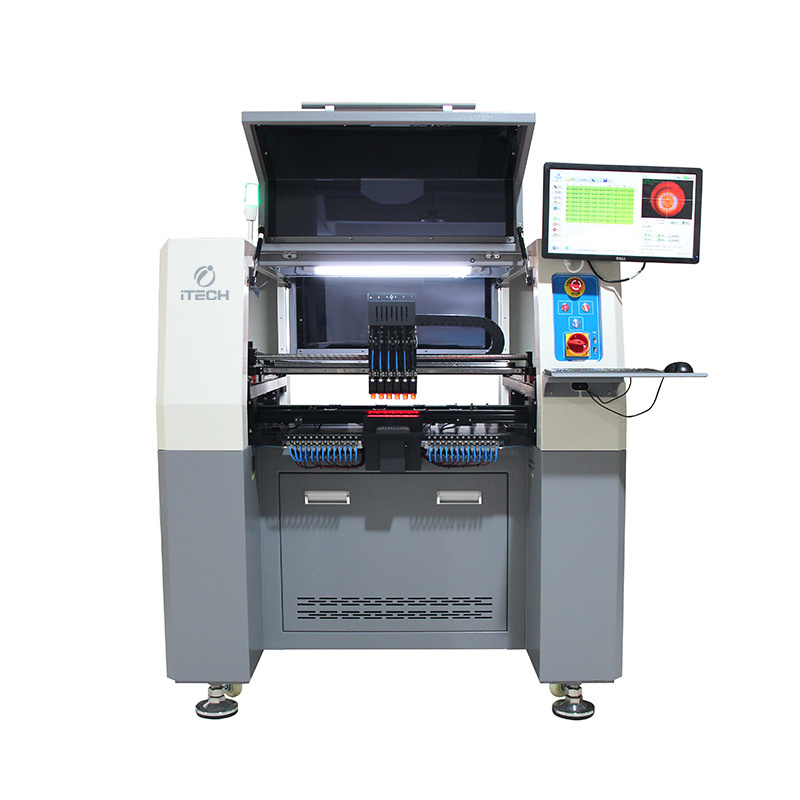

ITECH

-

Model Number:

-

PPM-C400BS

-

Product name:

-

SMT Pick and Place Machine

-

Mounting Precision:

-

0.025mm

-

Visual Mounting Speed:

-

8000 pcs/h

-

Feeder Type:

-

Yamaha CL Feeder,Electric Feeder

-

PCB Minimal Size:

-

45*45mm

-

PCB Maximum Size:

-

500*400mm

-

Number of Feeder:

-

64 Level

-

Motor:

-

Servo Motor

-

Outline Size:

-

1335*1200*1390mm

Product Description

PPM-C400BS

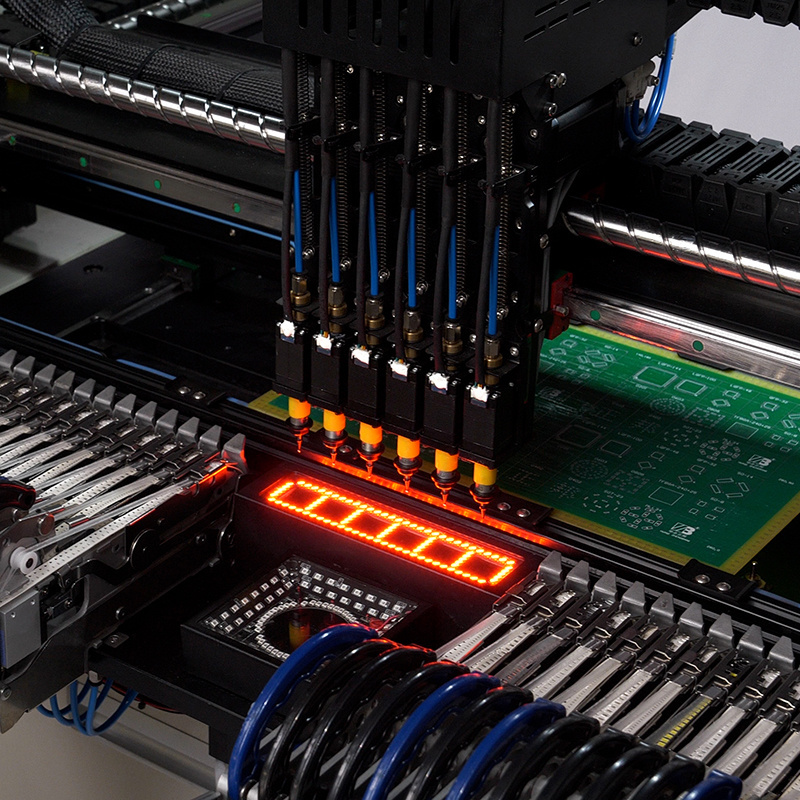

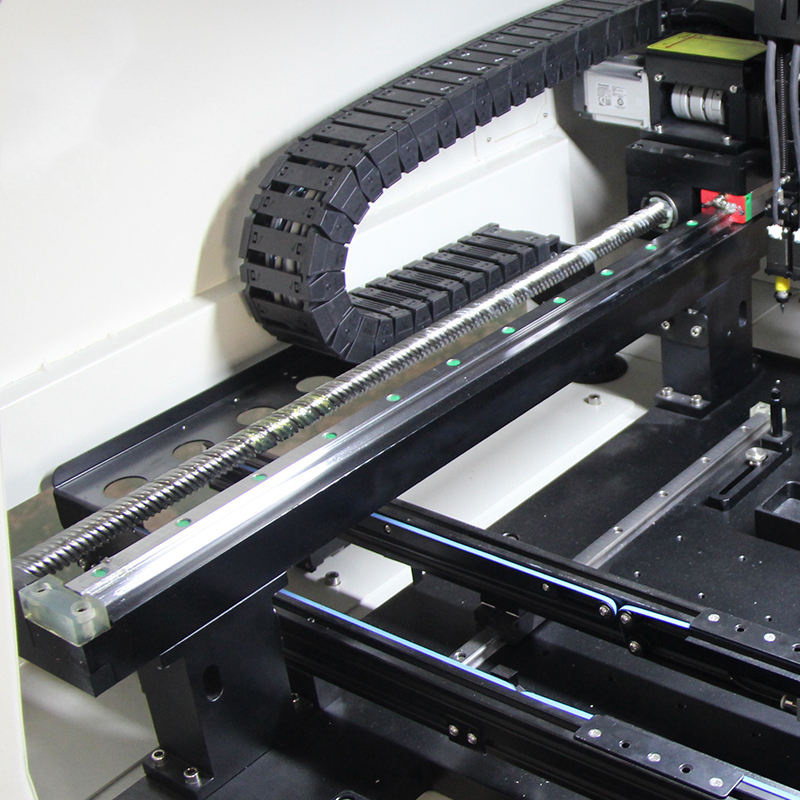

pick and place machine providing the embedded industrial WIN7 PC controller, eight sets of high-resolution CCD industrial camera vision correction system, online 6- head synchronous mounting. The transmission mechanism is equipped with Panasonic high-resolution servo motor, HIWIN linear guide, and TBI ball screw, which can maintain long-term high precision and stable mount. Machine with 64 pcs of YAMAHA CL 8mm feeder and supports CSV coordinate file import editing, maximum PCB size allow: 500 * 400mm. it is suitable for automatic mass production with high precision for normal resistance, LED chips , IC, BGA and so on.

PPM-C400BS

pick and place machine greatly improve the productivity and placement quality by dual-arm serial control technology six heads recognizing component at the same time. By applying the bus control technology, The whole machine modular wiring structure is more stable and beautiful , Furthermore, by applying 220v servo motor the total rated power is 1.2kw, being the lowest power and the smallest size among the same class component placer.It is widely used in intelligent appliance , LED , power supply, automotive electronics, main controller and etc.

|

Product Specification

|

|

|

|

|

||||

|

System

|

Project

|

Content

|

|

|

||||

|

Mounting system

|

Mounting numbers

|

6 pcs

|

|

|

||||

|

|

Precision

|

0.025mm

|

|

|

||||

|

|

Theoretical speed

|

11000 pcs/h

|

|

|

||||

|

|

Normal speed

|

9000 pcs/h

|

|

|

||||

|

|

Visual speed

|

8000 pcs/h

|

|

|

||||

|

|

Applicable element

|

RC( 0402 , 0603 , 0805 , 1206 etc)

|

|

|

||||

|

|

|

LED lamp beads (0603,0805,3014,5050 etc)

|

|

|

||||

|

|

|

Chip ( SOT , SOP , QFN , BGA etc)

|

|

|

||||

|

PCB

|

Minimal Size

|

10 x 10 mm

|

|

|

||||

|

|

maximum size

|

500×400 mm (no try)

|

|

|

||||

|

|

|

500×250 mm( with try)

|

|

|

||||

|

|

Thickness

|

≤ 2 mm

|

|

|

||||

|

|

Wraping allowable value

|

≤ 2 mm

|

|

|

||||

|

X,Y Motion Structure

|

Drive Type

|

Lead Screw + Guide Rail

|

|

|

||||

|

|

Drive Motor

|

Panasonic Servo Motor

|

|

|

||||

|

|

Type

|

Yamaha CL Feeder

|

|

|

||||

|

|

Specification

|

8mm,12mm,16mm,24mm,32mm

|

|

|

||||

|

|

Amount

|

64pcs

|

|

|

||||

|

|

Electric Feeder

|

3pcs

|

|

|

||||

|

|

Tubular Feeder

|

3 or 5

|

|

|

||||

|

|

Camera

|

CCD HD Camera

|

|

|

||||

|

|

Number

|

PCB Camera×1,HD Camera×1,High Speed Camera×6

|

|

|

||||

|

Control System

|

PC System

|

Microsoft WIN7

|

|

|

||||

|

|

Compatible File Format

|

.CSV,.TXT

|

|

|

||||

|

Vacuum

|

Vacuum Generation Method

|

Vacuum generator

|

|

|

||||

|

|

Vacuum value

|

-80kpa

|

|

|

||||

|

Machine

|

Power

|

350W

|

|

|

||||

|

|

Power supply

|

AC220V±10% 50Hz

|

|

|

||||

|

|

Dimension

|

L 1335 × W 1200 × H 1390 mm

|

|

|

||||

|

|

Net weight

|

440kg

|

|

|

||||

Product Details

Recommend Products

About Us

Wenzhou Zhengbang Electronic Equipment Co., Ltd.

Established in 2006, Wenzhou Zhengbang Electronic Equipment Co., Ltd is a professional manufacturer of machine and assembly line accessories as the THT welding equipment series, SMT welding equipment series and Assembly line series. It serves more than two hundred thoudsand customers. Our products have been sold well in China and all over the world. Our main export countries and regions include North America, South America, Europe, Southeast Asia, Africa and Middle East nearly 60 countries. Insisting to the operational principle of "Quality first, Customers first". All our staff are ready to serve you with our best efforts. We could provide you the highly competitive prices and reliable quality. We're sincerely looking forward to serving you in the nearest future.

Hot Searches