- Product Details

- {{item.text}}

Quick Details

-

Dimensions(L*W*H):

-

3100mmx2100mmx2400mm

-

Weight:

-

3550kg

-

Model:

-

4 colour flexo printing machine

-

Application:

-

film, paper ,foil, label etc.

-

Printing colors:

-

1-10 color

-

Printing speed:

-

60-80m/min

-

Max. printing width:

-

320mm/450mm/480mm

-

Max. unwinding diameter:

-

600mm

-

Max. rewinding diameter:

-

600mm

-

printing repeat:

-

175-580mm

-

Registration precision:

-

±0.10mm

-

Total power:

-

38kw

-

Certification:

-

ISO9001 CE

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

DABA

-

Voltage:

-

380V

-

Dimensions(L*W*H):

-

3100mmx2100mmx2400mm

-

Weight:

-

3550kg

-

Model:

-

4 colour flexo printing machine

-

Application:

-

film, paper ,foil, label etc.

-

Printing colors:

-

1-10 color

-

Printing speed:

-

60-80m/min

-

Max. printing width:

-

320mm/450mm/480mm

-

Max. unwinding diameter:

-

600mm

-

Max. rewinding diameter:

-

600mm

-

printing repeat:

-

175-580mm

-

Registration precision:

-

±0.10mm

-

Total power:

-

38kw

-

Certification:

-

ISO9001 CE

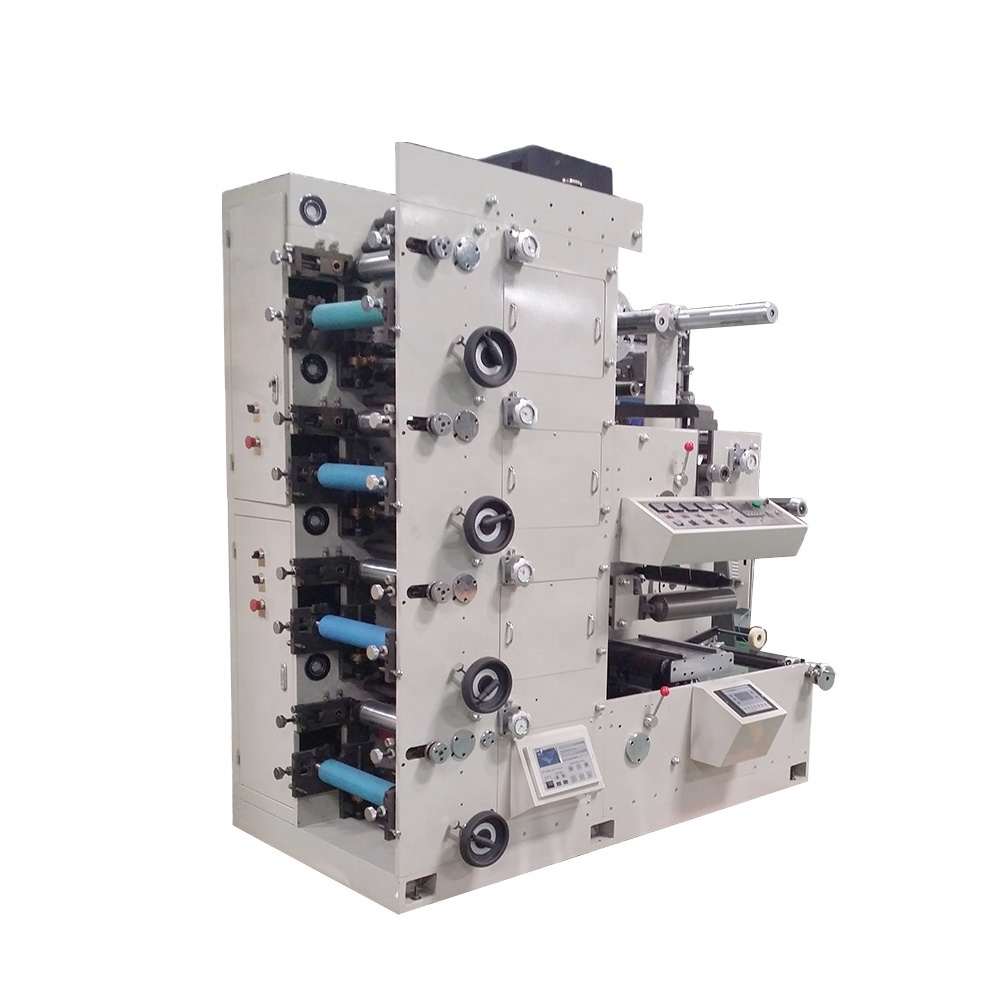

Hot sale 4 colour flexo printing machine

This machine is suitable for print on paper,film,foil etc. roll material, It is an ideal equipment for label area. The flexo printing machine has multi- function: Varnishing , die cutting, slitting , sheeting, cold stamping etc. for optional. Printing range is wide, ink is environmental, low cost, high effient, high speed.

|

Model

|

320mm

|

480mm

|

|

Printing Speed

|

60-80m/min

|

60-80m/min

|

|

Printing Color

|

1-10 colors

|

1-10 colors

|

|

Max. Unwinding Width

|

330mm

|

510mm

|

|

Max. Printing Width

|

320mm

|

480mm

|

|

Max. Unwinding Dia.

|

600mm

|

600mm

|

|

Max. Rewinding Dia.

|

600mm

|

600mm

|

|

Printing Girth

|

175-580mm

|

175-580mm

|

|

Precision of Registering

|

±0.10mm

|

±0.10mm

|

|

Dimensions

|

L2.1M*W1.35M*H3.5M

|

L2.1M*W1.35M*H3.5M

|

|

Machine Weight

|

About 2800KGS

|

About 2800KGS

|

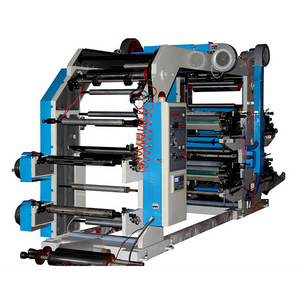

Main Features

1) Main motor adopts frequency stepless speed regulator motor.

2) Unwinder and rewinder are controlled by magnetic powder brake,clutch and tension inspector.Tension controller is automatic.

3) Each printing unit adopt 360° to regulation.

4)Each printing unit has one IR Oven. Every IR oven can exchange UV drying system.

5)Sending paper,printing ,polished,infared drying or UV drying,laminating,rewinding step by step at one printing process.

①UV oven

②Video inspecting system/ Camera

③Slitting device

④Cold / Hot stamping device

⑤Corona treatment

⑥Conveyor

⑦Pouching device ........(Please contact with me to get more information,thanks)

Delivery Details : Printing Press :30 working days

Die Cutting machine:15 working days

Slitting Machine: 7 working days