- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, Other

-

Place of Origin:

-

Gongyi China

-

Brand Name:

-

ROCKWELL

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1200x1200x1600mm

-

Weight (KG):

-

750 kg

-

Raw material:

-

Cement, sand, mineral powder

-

Keywords 1:

-

small brick making machine

-

Usage:

-

Industrial Profiles

-

Worker:

-

1-2 People

-

Keywords 2:

-

mud brick making machine

-

Motor:

-

4.8kw

-

After Warranty Service:

-

Online

-

Color:

-

Customer's Request

-

Advantage:

-

High Efficiency

-

Capacity:

-

45s

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, Autoclaved aerated concrete block (AAC), Other

-

Brick Raw Material:

-

Cement, sand, mineral powder, etc.

-

Production Capacity (Pieces/8 hours):

-

4480 pcs/8hours, 2500 pcs/8hours, 3400 pcs/8hours, 1920 pcs/8hours, 5760 pcs/8hours, 1500 pcs/8hours, 1280 pcs/8hours, 3000 pcs/8hours, 12000 pcs/8hours, 3200 pcs/8hours, 2560 pcs/8hours, 1000 pcs/8hours, 800 pcs/8hours, Other

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, Other

-

Place of Origin:

-

Gongyi China

-

Brand Name:

-

ROCKWELL

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1200x1200x1600mm

-

Weight (KG):

-

750 kg

-

Raw material:

-

Cement, sand, mineral powder

-

Keywords 1:

-

small brick making machine

-

Usage:

-

Industrial Profiles

-

Worker:

-

1-2 People

-

Keywords 2:

-

mud brick making machine

-

Motor:

-

4.8kw

-

After Warranty Service:

-

Online

-

Color:

-

Customer's Request

-

Advantage:

-

High Efficiency

-

Capacity:

-

45s

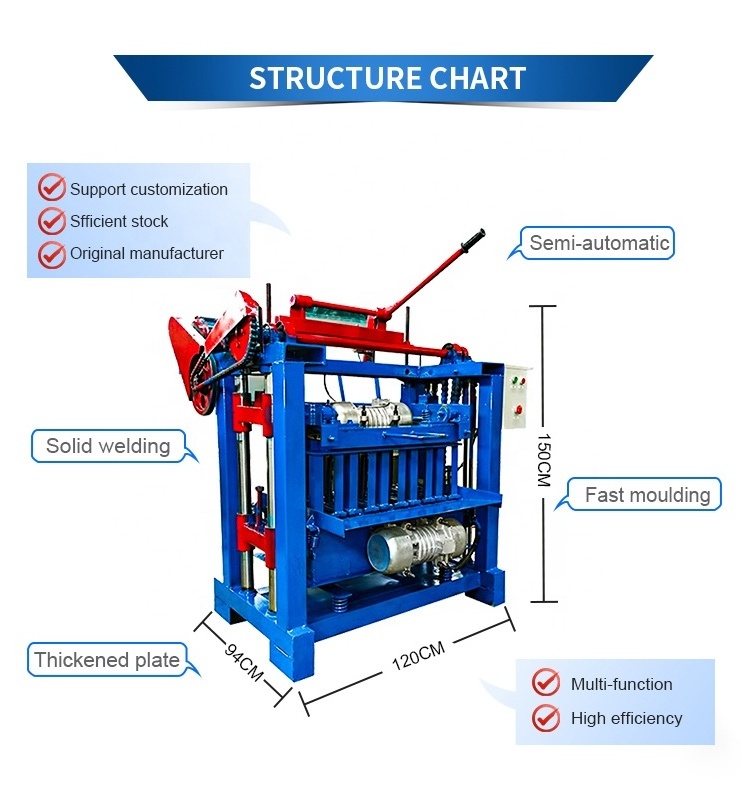

Product Description

Brief introduction of Brick Machine

This is a cement brick making machine. The type is 4 bricks in 35 seconds A. It can ba molded into various types. Two person operation, it's convinient and cheap.

This kind of equipment is also known as the burn-free brick machine, that is to say, the produced cement bricks or hollow blocks do not need to be sintered, and can be shipped out of the factory after a short period of drying.The brick machines produced by our factory include manual brick machines, semi-automatic brick machines, and hydraulic fully automatic brick machines.

|

Model

|

Dimission(mm)

|

Power (kw)

|

Weight(kg)

|

|

4-35A

|

1200*1200*1600

|

4.8

|

750

|

|

4-35B

|

1200*1200*2000

|

4.8

|

800

|

|

4-30A

|

1200*1200*1600

|

5.5

|

900

|

|

4-30B

|

1200*1200*2000

|

5.5

|

950

|

|

QYJ-A

|

1200*1200*1600

|

3.7

|

750

|

|

4-40C

|

1700*1700*2500

|

8.55

|

1500

|

|

4-40A

|

1500*1300*1800

|

7.5

|

1100

|

The cement brick making machine uses slag, fly ash, stone powder, sand, stones, cement, etc. as raw materials, scientifically proportions, mixes with water, and presses the cement brick, hollow block or colored pavement brick through high-pressure brick making machinery.

Here's the finished product.

Advantages and other products

Features:

1.The machine is made of strong square steel welded, extremely strong shock-resistant,Stable performance;

1.The machine is made of strong square steel welded, extremely strong shock-resistant,Stable performance;

2.The mold box adopts column sliding, with compact, synchronous and stable lifting, and the forming rate of block is greatly improved;

3.The pressing head can slide and shift, which is convenient to touch the box cloth and greatly improve the efficiency;

4.The lifting part of the mold box is installed to prevent the press head from damaging the machine in action.

Hot Searches