- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

25 mm

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

4800 KG

-

Place of Origin:

-

China

-

Marketing Type:

-

Hot Product 2024

-

Application:

-

Metal Sheet Cutting

-

Product name:

-

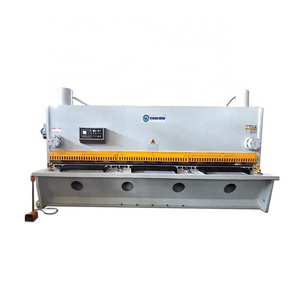

Hydraulic Cnc Shearing Machine

-

Name:

-

QC11K Hydraulic Guillotine Shearing Machine

-

Type:

-

Hydraulic Cutting Machine

-

Keyword:

-

Hydrualic Shearing Machine

-

Cutting material:

-

Metal Sheet

-

Function:

-

Cutting Sheet Plate

-

Color:

-

Customised

-

Voltage:

-

380V

-

CNC or not:

-

CNC Cutter Machine

Quick Details

-

Max. Cutting Width (mm):

-

3200

-

Max. Cutting Thickness (mm):

-

6 mm

-

Blade Length (mm):

-

3300 mm

-

Throat Depth (mm):

-

25 mm

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

4800 KG

-

Place of Origin:

-

China

-

Marketing Type:

-

Hot Product 2024

-

Application:

-

Metal Sheet Cutting

-

Product name:

-

Hydraulic Cnc Shearing Machine

-

Name:

-

QC11K Hydraulic Guillotine Shearing Machine

-

Type:

-

Hydraulic Cutting Machine

-

Keyword:

-

Hydrualic Shearing Machine

-

Cutting material:

-

Metal Sheet

-

Function:

-

Cutting Sheet Plate

-

Color:

-

Customised

-

Voltage:

-

380V

-

CNC or not:

-

CNC Cutter Machine

DURMAPRESS

®

QC11Y NC Hydraulic Guillotine Shearing Machine

Product Details

Machine Body

The foundation of every Durmapress machine is a solid, mono-block frame which made from high yield steel. Which means our machine will perform accurately and reliably year after year. Every machine frame is tempered.

We' re so confident in our frames so that we offer a 15-year warranty with our standard machines.

Working Bench

Rolling steel ball of workbench can reduce friction , protect the workpiece surface ; delicate design is convenient for cutting petty materials by hand.

Press Cylinder

Made by high-quality alloy tool steel , the machine can meet the impacting load and high wear resistance requirements when working.

Standard materials: 9GrSi/6CrW2Si

Can Use for 4 sides

Use French Schneider electrics to ensure machine stability , High quality electric parts can perform well even the electricity is not stable and customs can easily get the replacement anywhere in

the world.

Compared to traditional stepper motors, the advantages of using servo motors include: improve the accuracy to ±0.01mm, the noise decrease to 25 decibels, reduce energy consumption by 60%, consume 70% less hydraulic oil and 30% higher efficiency.

Product Paramenters

|

Model

|

Cutting Thickness(mm)

|

Cutting Length(mm)

|

Cutting Angle

|

Power(kw)

|

Weight(kg)

|

|

QC11Y-6*2500

|

6

|

2500

|

0.5-2.0

|

7.5

|

6400

|

|

QC11Y-6*3200

|

6

|

3200

|

0.5-2.0

|

7.5

|

7500

|

|

QC11Y-8*2500

|

8

|

2500

|

0.5-2.0

|

7.5

|

7200

|

|

QC11Y-8*3200

|

8

|

3200

|

0.5-2.0

|

7.5

|

8000

|

|

QC11Y-12*2500

|

12

|

2500

|

0.5-2.0

|

11

|

10300

|

|

QC11Y-12*3200

|

12

|

3200

|

0.5-2.0

|

11

|

11300

|

|

QC11Y-16*2500

|

16

|

2500

|

0.5-2.0

|

11

|

11500

|

|

QC11Y-16*3200

|

16

|

3200

|

0.5-2.0

|

15

|

12600

|

|

QC11Y-20*3200

|

20

|

3200

|

0.5-2.0

|

22

|

16500

|

Certifications

Our Company

Customers Feedback

Exhibition

FAQ

Hot Searches