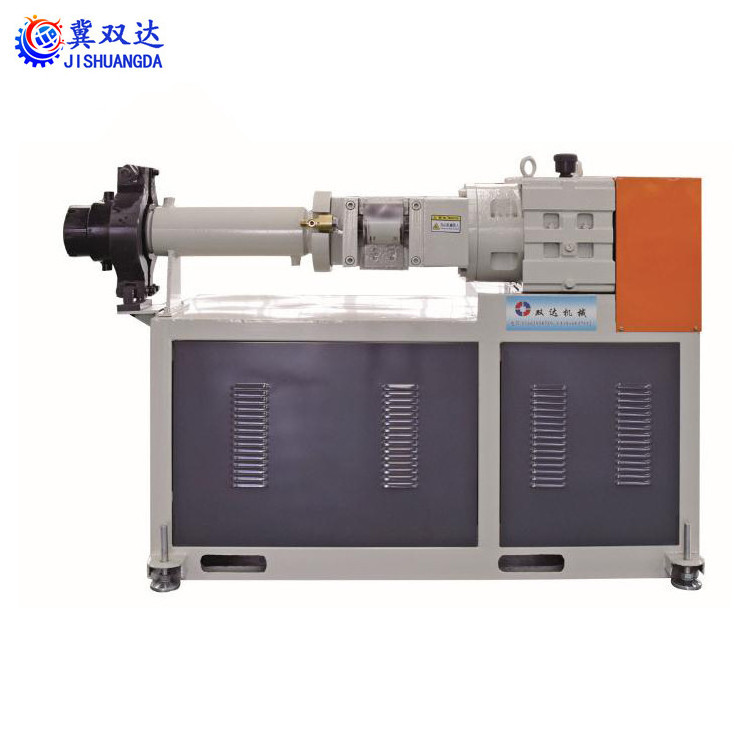

Nitride depth: 0.4-0.7mm

Nitride hardness: Screw 850HV barrel 930HV

Screw structure : Special

Screw speed: 10-80rpm

roughness of inner barrel:0.4um

Roughness of Screw screw edge: 0.4um

Reducer ration 16:1

Motor power 15kw