- Product Details

- {{item.text}}

Quick Details

-

Height of side wall:

-

80 mm~400mm

-

Stucture material:

-

carbon steel, stainless steel

-

Keyword:

-

sidewall belt conveyor system

-

Material of belt:

-

rubber, PVC, steel core

-

Distance between baffles:

-

126 mm

-

Max materials size and belt speed:

-

1.0/50 m/s

-

Angle of inclination:

-

0~90

-

Auxiliary device:

-

rain cover

-

Product name:

-

Factory Supply sidewall belt conveyor system

Quick Details

-

Power:

-

subject to the model

-

Warranty:

-

1 Year

-

Place of Origin:

-

Henan, China

-

Height of side wall:

-

80 mm~400mm

-

Stucture material:

-

carbon steel, stainless steel

-

Keyword:

-

sidewall belt conveyor system

-

Material of belt:

-

rubber, PVC, steel core

-

Distance between baffles:

-

126 mm

-

Max materials size and belt speed:

-

1.0/50 m/s

-

Angle of inclination:

-

0~90

-

Auxiliary device:

-

rain cover

-

Product name:

-

Factory Supply sidewall belt conveyor system

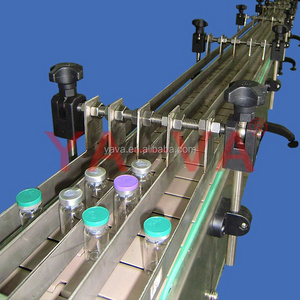

Factory Supply Sidewall Belt Conveyor System

Application:

- Coal and wood-chip fired power stations

- Underground mining (coal and ore)

- Shaft conveying for tunnelling and underground mining

- Steel industry

- Ship loading and unloading, ship to ship loading

- Sand preparation in foundry plants

- Silo feeding

- Slope conveying in openpit mining

- Waste recycling, soil purification and water treatment

- Handling of large material flows in the horizontal path

- A wide range of material can be handled which pause problems in other transportation means. Sidewall belt conveyor system can be used for abrasive, wet, dry, sticky or dirty material. The lump size of the transported material is limited by the width of the belt. Belts up to 1400 mm wide are used in mining industry.

- Higher capacity can be handled than any other form of conveyor at a considerably lower cost, ton/km. Conveyor belts with capacity of 11000t/h and even higher can be deployed to match with higher capacity mining machinery.

- Longer distances can be covered more economically than any other transportation system. A single belt conveyor or a series of belt conveyors can do this.Sidewall Belt Conveyor System can be adopted for cross-country laying.

- By the use of many forms of ancillary equipment such as mobile trippers or spreaders bulk material can be distributed and deposited whenever required.

- Many other functions can be performed with the basic conveying like weighing, sorting, picking, sampling, blending, spraying, cooling, drying etc.

- Structurally it is one of the lightest forms of conveying machine. It is comparatively cheaper and supporting structures can be used for many otherwise impossible structures such as crossing rivers, streets and valleys.

- Sidewall Belt Conveyor System can be adopted for special purposes (fire resistant, wear resistant, corrosion resistant, high angle negotiation etc.) and can be integrated with other equipment.

- Sidewall Belt Conveyor System can be horizontal, incline or decline or combination of all.

- Minimum labour is required for the operation and maintenance of belt conveyor system.

-

In underground mine transport, Sidewall Belt Conveyor System can be used in thin seams as it eliminates the rock works that might otherwise be required to gain haulage height. Moreover, belt conveyor can provide continuous haulage service from pit bottom to the surface.

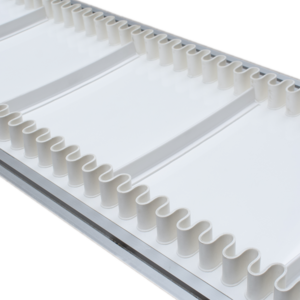

Working Principle:

- The horizo loading section a deflection wheel bends the belt into the feeding of the bulk material takes place on a mostly horizontal feed path, where the side wall belt is supported by loading impact idlers. The feeding of the conveyed material can be achieved by direct feeding from a hopper, over a chute, a feeding belt or a feeding pulley. The selection of the optimum feeding station depends on the properties of the bulk material and the belt speed of Sidewall Belt Conveyor System. The upward and downward strands are encased from the bottom to the top. Substructures or support rollers are not necessary in this section.

- The vertical section leads over a deflection curve into the horizontal discharge section. The deflection curve is made up of a number of high specification pulleys. These pulleys experience the vectored load of deflecting the belt tension from vertical to horizontal.

- At the drive pulley, the bulk material is discharged and the belt is returned to the back going strand. Depending on the bulk material properties, the drive pulley is followed by a beater wheel for belt cleaning in the return side. The beater is self-driven. Material that fails from the belt goes into the main delivery chute. Lateral deflection wheels turn the belt from the horizontal back to the vertical.

| Belt | Belt is used for moving and supporting surface on which the conveyed material rides. It is the tractive element. The type of belt used need to depend on the nature of materials to be transported. |

|

| Idler | Idlers are the supports for the carrying and return stands of the belt. |

|

| Drive | Drive that imparts power to one or more pulleys to move the belt and its loads. | |

| Structure | Structure is the support and maintains the alignments of the idlers and pulleys. Besides, it also supports the driving machinery. | |

| Pulley |

Drive pulley is normally fixed after installation and requires no adjustment. For most application, the pulley face is crowned and rubber lagged. However, on some large belts, due to the type of tensile and cross-stabilizing members, it is not advisable to crown the pulley as damage may result to the base belt.

|

|

Belt Width (mm) |

Sidewall Height (mm) |

Conveyor Quantity at certain angles Q(m 3 /h) |

|||

|

30° |

45° |

60° |

90° |

||

|

500 |

120 |

55 |

36 |

25 |

11 |

|

120 |

96 |

63 |

43 |

19 |

|

|

650 |

160 |

119 |

83 |

58 |

25 |

|

160 |

156 |

109 |

76 |

33 |

|

|

800 |

200 |

190 |

137 |

97 |

43 |

|

240 |

247 |

189 |

140 |

63 |

|

|

1000 |

200 |

266 |

191 |

134 |

75 |

|

240 |

347 |

267 |

197 |

101 |

|

|

1200 |

240 |

400 |

308 |

228 |

122 |

|

300 |

491 |

379 |

285 |

167 |

|

|

1400 |

300 |

611 |

473 |

355 |

159 |

|

400 |

771 |

590 |

435 |

195 |

|

For Factory Supply Sidewall Belt Conveyor System:

1. What is the conveying material and its physical characteristics? such as bulk density, feeding size, temperature, mositure content etc.

2. What is the processing capacity of the conveyor?

3. What is the inclination angle of the conveyor?

4. What is the lifting height (distance between inlet and outlet)?

5. What is the length of horizontal section?