- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

WP-300

-

Material:

-

PP

-

Color:

-

White and blue

-

Brick Size:

-

300*150*150mm

-

Application:

-

construction

-

Name:

-

Plastic Injection Molding

-

Usage:

-

making concrete block

-

Type:

-

Construction Industry

-

Item:

-

WP-300

-

Product name:

-

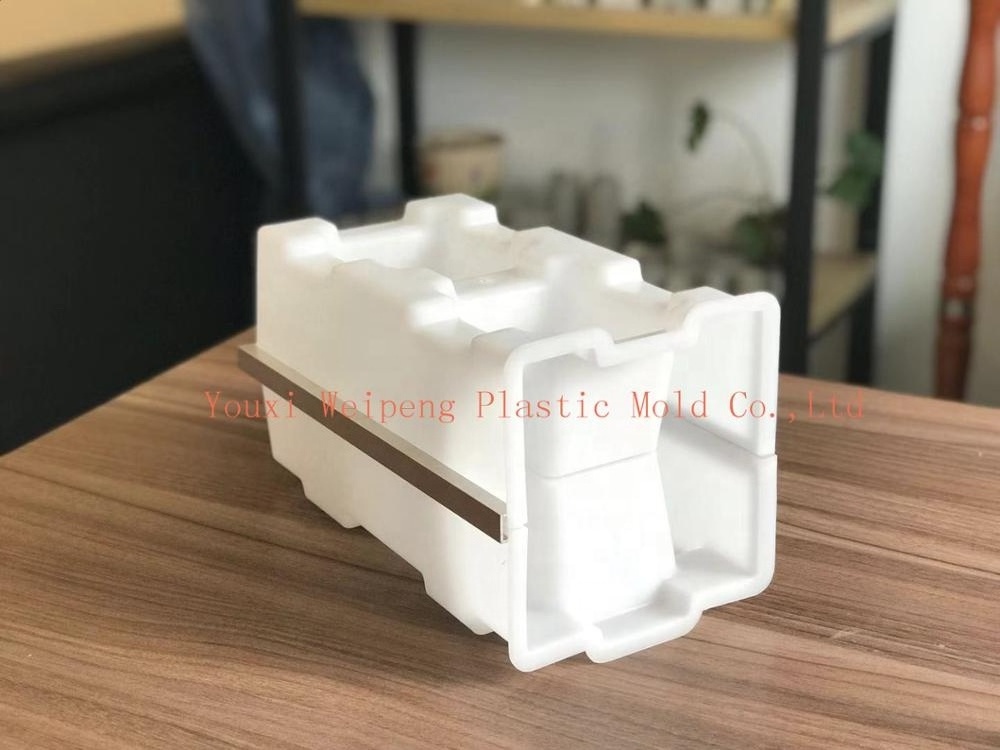

insulation brick mold

-

Mould Life:

-

1000times

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

WP

-

Model Number:

-

WP-300

-

Material:

-

PP

-

Color:

-

White and blue

-

Brick Size:

-

300*150*150mm

-

Application:

-

construction

-

Name:

-

Plastic Injection Molding

-

Usage:

-

making concrete block

-

Type:

-

Construction Industry

-

Item:

-

WP-300

-

Product name:

-

insulation brick mold

-

Mould Life:

-

1000times

Brief Introduction

this is our new block mould design ,it can replace the normal block machine to produce the concrete blocks for your house building ,also then final block from this mould is with smooth surface and easy to paint and decorate the indoor and outdoor wall .most importantly ,this block can be 100% interlock together which will save more cementduring building and more stable struture for the whole house.

it can be used for a long time and just need a vibrating table and pan concrete vmixer then you can do producing ,it 's a perfect choice for a small amd medium-sized factory.

Y ou would like to know:

---------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Environmentally friendly.

2. Many times faster to install than concrete kerbs due to reduced weight.

3. Can be handled, lifted and installed without machines.

4. Does not chip or crack; practically indestructible.

5. Resistant to UV, acids, petrol, oil, insects and plants.

How to demould smoothly and get strong blocks :

---------------------------------------------------------------------------------------------------------------------------------------------------------------------

- The moulding oil should use the wasted engine oil. ( Note: can't use diesel, which dry too quickly)

- To the demoulding time, you should demould when the concrete dry at a certain degree,at which degree, the concrete is concreted,but won't stick on the mould when demould. (to this point, you can try several times to get the suitable idea.)

- To get the strong block, except the aboved points, you should vibrate to release the air, and make cement and other materials fasten each other.

PACKAGING

Cartons

1. We have large stock and prompt delivery .

2.Good After-sales service