- Product Details

- {{item.text}}

Quick Details

-

Power:

-

1.5*2kw

-

Weight (KG):

-

2400

-

Marketing Type:

-

New Product

-

Product name:

-

Vibration Fluid Bed Dryer

-

Name:

-

Vibrating Fluidized Bed Dryer

-

Keywords:

-

China Vibration Fluidized Bed Dryer

-

Function:

-

Food Vegetable Fruit Dehydrator

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Usage:

-

Reduce Material's Moisture

-

Heating source:

-

Electricity

-

Raw material:

-

Multiple Material

-

Feature:

-

High Efficiency Low Cost

-

Application material:

-

Vegetable Herbal Fruit Chemical

Quick Details

-

Type:

-

Fluid Bed Drying Equipment

-

Place of Origin:

-

China

-

Voltage:

-

custom

-

Power:

-

1.5*2kw

-

Weight (KG):

-

2400

-

Marketing Type:

-

New Product

-

Product name:

-

Vibration Fluid Bed Dryer

-

Name:

-

Vibrating Fluidized Bed Dryer

-

Keywords:

-

China Vibration Fluidized Bed Dryer

-

Function:

-

Food Vegetable Fruit Dehydrator

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Usage:

-

Reduce Material's Moisture

-

Heating source:

-

Electricity

-

Raw material:

-

Multiple Material

-

Feature:

-

High Efficiency Low Cost

-

Application material:

-

Vegetable Herbal Fruit Chemical

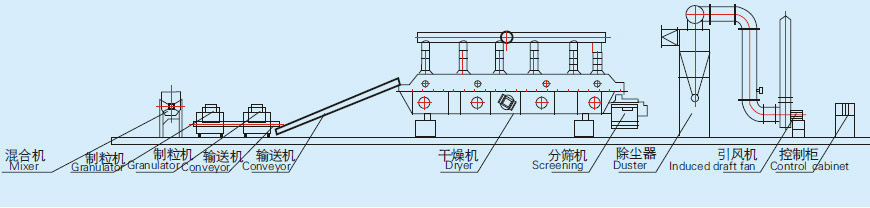

Introduction

WKS series of vibration fluid bed dryer is a continuous drying equipment for non-sticky particles. Its working principle is: cold air is filtered through the filter, and then goes into the heater, and is heated to a certain temperature, then hot air is

distributed into the lower bed via multiple inlets and flows up through perforated plate of the bed. Material goes evenly into the bed through screw feeder, under the action of the vibration force, the material moves up forward continuously along the horizontal direction, while undergoes heat exchange with the hot air coming up from bottom, the moisture of material is evaporated rapidly, and the wet air is discharged from the exhaust fan, and the material is fully dried and discharged from the discharge port.

WKS series of vibration fluid bed dryer is a continuous drying equipment for non-sticky particles. Its working principle is: cold air is filtered through the filter, and then goes into the heater, and is heated to a certain temperature, then hot air is

distributed into the lower bed via multiple inlets and flows up through perforated plate of the bed. Material goes evenly into the bed through screw feeder, under the action of the vibration force, the material moves up forward continuously along the horizontal direction, while undergoes heat exchange with the hot air coming up from bottom, the moisture of material is evaporated rapidly, and the wet air is discharged from the exhaust fan, and the material is fully dried and discharged from the discharge port.

|

Model

|

Fluid bed area

(㎡) |

Inlet temperature (℃)

|

Outlet temperature (℃)

|

Evaporation capacity (kg/h)

|

Motor

(kW) |

Weight

(kg) |

|

WKS-FBD-3*0.3

|

0.9

|

70-140

|

40-70

|

20-35

|

0.8*2

|

1250

|

|

WKS-FBD-4.5*0.3

|

1.35

|

70-140

|

40-70

|

35-50

|

0.8*2

|

1250

|

|

WKS-FBD-4.5*0.45

|

2.025

|

70-140

|

40-70

|

50-70

|

1.1*2

|

1670

|

|

WKS-FBD-4.5*0.6

|

2.7

|

70-140

|

40-70

|

70-90

|

1.1*2

|

1670

|

|

WKS-FBD-6*0.45

|

2.7

|

70-140

|

40-70

|

80-100

|

1.5*2

|

2100

|

|

WKS-FBD-6*0.6

|

3.6

|

70-140

|

40-70

|

100-130

|

1.5*2

|

2400

|

|

WKS-FBD-6*0.75

|

4.5

|

70-140

|

40-70

|

120-140

|

2.2*2

|

2840

|

|

WKS-FBD-6*0.9

|

5.4

|

70-140

|

40-70

|

140-170

|

2.2*2

|

3160

|

|

WKS-FBD-7.5*0.75

|

5.625

|

70-140

|

40-70

|

150-180

|

2.2*2

|

3200

|

|

WKS-FBD-7.5*0.9

|

6.75

|

70-140

|

40-70

|

160-210

|

3.0*2

|

3600

|

Our Factory

Customer photos

Hot Searches