- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Customized

-

Surface:

-

Blank, grounded or mirror polished

-

Advantage:

-

Excellent wear resistance,good performance

-

Quality Certificate:

-

ISO9001,ISO14001,OHSAS18001

-

Type:

-

Power Tool Parts

-

Material:

-

Tungsten Carbide WC+Co

-

Usage:

-

PCB Tools

-

Application:

-

Wood Cutting

-

Chemical Composition:

-

Co-WC

-

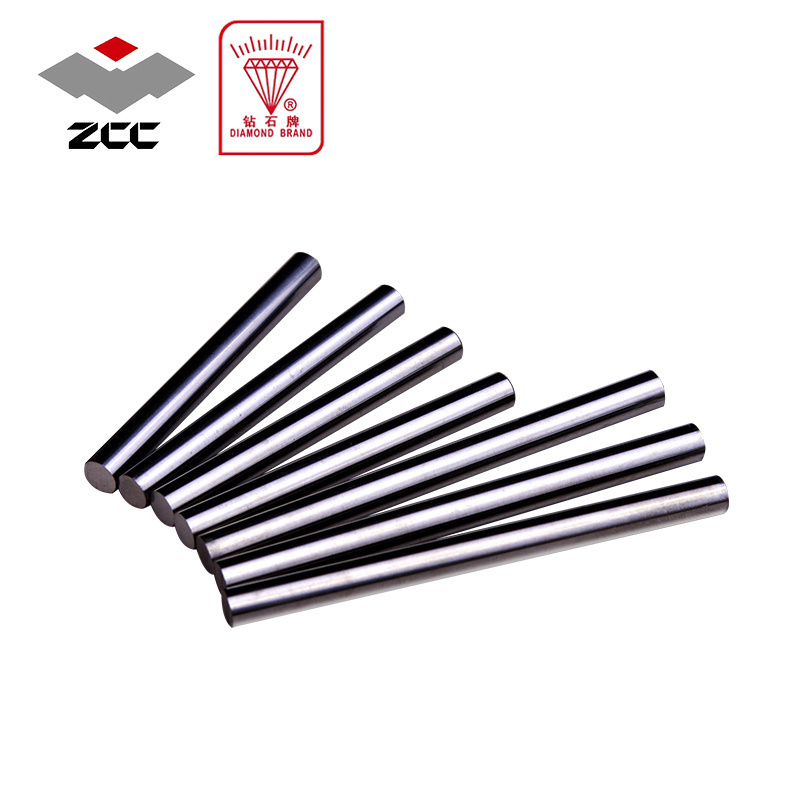

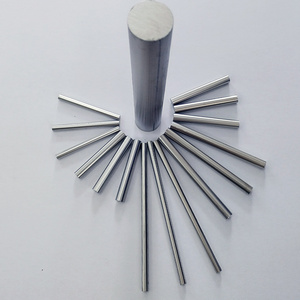

Commodity Name:

-

Tungsten Cemented Carbide Rod

-

Product name:

-

Tungsten Carbide Bar

Quick Details

-

Alloy Specification:

-

K10/K20/K30

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

Diamond brand

-

Model Number:

-

Customized

-

Surface:

-

Blank, grounded or mirror polished

-

Advantage:

-

Excellent wear resistance,good performance

-

Quality Certificate:

-

ISO9001,ISO14001,OHSAS18001

-

Type:

-

Power Tool Parts

-

Material:

-

Tungsten Carbide WC+Co

-

Usage:

-

PCB Tools

-

Application:

-

Wood Cutting

-

Chemical Composition:

-

Co-WC

-

Commodity Name:

-

Tungsten Cemented Carbide Rod

-

Product name:

-

Tungsten Carbide Bar

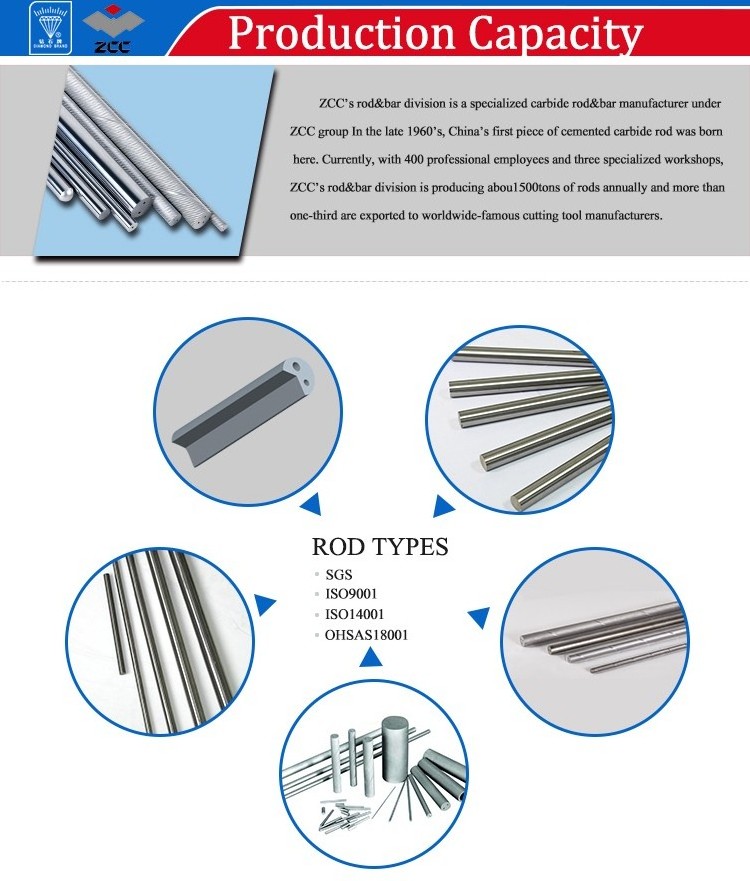

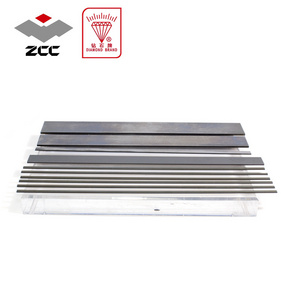

Application of Carbide rods and bars

Solid tungsten carbide rods are used for cutting aluminum alloy, cast iron, stainless steel, refractory alloy steel, nickel based alloy, titanium alloy and nonferrous metals.widely used processed as HSS Cutting tool, carbide end mills, carbide cutting tool, NAS cutting tool, carbide end mill, aerospace cutting tool, carbide drill, high speed steel, milling cutter Core drill, taperd end mills, metric end mills, miniature end mills, pilot reamer, electronics cutter, step drill, metal cutting saw, double margin drill, gun barrel, angle milling cutter, carbide burrs, carbide tipped cutter.

Specification of Carbide rods and bars

| GRADE | YL06C | YL10.2 | YL10A | YF06 | XF20S | XF30S | XT30S | XU30 | XU09S | XU10W | |

| Drilling | * | * | * | * | * | ||||||

| Milling | * | * | * | * | * | * | * | * | * | ||

| Reaming | * | ||||||||||

| P | General carbon steel | ^ | # | ^ | ^ | # | |||||

| M | Stainless steel | # | ^ | ||||||||

| K | Cast Iron | ^ | # | ^ | ^ | # | |||||

| S | Ti | # | ^ | ||||||||

| HRSA | # | ||||||||||

| N | Al-Mg | ^ | # | ^ | ^ | ^ | # | ||||

| H | Hard steel | ^ | |||||||||

| Others | Plastic | # | # | ||||||||

| CFRP | ^(coated) | ||||||||||

| Wood | ^ | # | ^ | ||||||||

| Ceramic | ^(coated) |

| Cemented Carbide Rods for PCB Tools | ||||

| Type | Diameter(mm) | Tolerance(mm) | Length(mm) | Tolerance(mm) |

| BΦ3.21×38.5 | 3.21 | 0/+0.02 | 38.5 | -0.10/+0.2 |

| BΦ3.22×40 | 3.22 | 0/+0.04 | 40 | 0/+0.5 |

| BΦ3.22×45 | 3.22 | 0/+0.04 | 45 | 0/+0.5 |

| BΦ3.25×50 | 3.25 | 0/+0.05 | 50 | 0/+0.5 |

| BΦ3.25×38.7 | 3.25 | 0/+0.05 | 38.7 | -0.20/+0.3 |

| BΦ3.5×38.5 | 3.5 | +0.05/0.25 | 38.5 | ±0.20 |

| BΦ4.0×38.5 | 4.0 | +0.05/0.25 | 38.5 | ±0.20 |

| BΦ4.5×38.5 | 4.5 | +0.05/0.25 | 38.5 | ±0.20 |

| BΦ5.0×38.5 | 5.0 | +0.05/0.25 | 38.5 | ±0.20 |

| BΦ5.5×38.5 | 5.5 | +0.05/0.25 | 38.5 | ±0.20 |

| BΦ6.0×38.5 | 6.0 | +0.05/0.25 | 38.5 | ±0.20 |

| BΦ6.5×38.5 | 6.5 | +0.05/0.25 | 38.5 | ±0.20 |

| BΦ1.2×110 | 1.2 | 0/+0.2 | 110 | 0/+2 |

| BΦ1.35×110 | 1.35 | 0/+0.2 | 110 | 0/+2 |

| BΦ1.5×110 | 1.5 | 0/+0.2 | 110 | 0/+2 |

| BΦ1.8×110 | 1.8 | 0/+0.2 | 110 | 0/+2 |

| BΦ2.0×110 | 2.0 | 0/+0.2 | 110 | 0/+2 |

| Other types | ||||

| BΦ3.5*12.5 | BΦ3.5*13.0 | BΦ3.5*13.2 | BΦ2.0*24.5 | BΦ3.25*12.5 |

| BΦ4.0*12.5 | BΦ4.0*13.0 | BΦ4.0*13.2 | BΦ2.0*25.5 | BΦ3.25*12.7 |

| BΦ4.5*12.5 | BΦ4.5*13.0 | BΦ4.5*13.2 | BΦ2.0*26 | BΦ3.25*13.1 |

| BΦ5.0*12.5 | BΦ5.0*13.0 | BΦ5.0*13.2 | BΦ2.0*28 | BΦ3.25*14.5 |

| BΦ5.5*12.5 | BΦ5.5*13.0 | BΦ5.5*13.2 | BΦ2.0*31 | BΦ3.3*13.1 |

| BΦ6.0*12.5 | BΦ6.0*13.0 | BΦ6.0*13.2 | BΦ3.26*14.0 | BΦ4.0*46 |

| BΦ6.5*12.5 | BΦ6.5*13.0 | BΦ6.5*13.2 | BΦ3.25*11.5 | BΦ6.0*40 |

| BΦ7.0*12.5 | BΦ7.0*13.0 | BΦ7.0*13.2 | BΦ3.25*12.0 | BΦ6.0*50 |