Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Outsole Material:

-

EVA

-

Feature:

-

Breathable

-

Toe Style:

-

Iron toe

-

Place of Origin:

-

Shandong, China

-

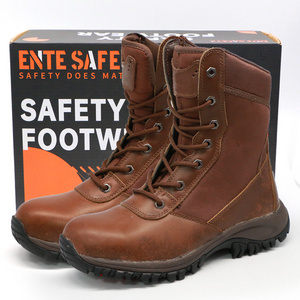

Brand Name:

-

ENTE SAFETY

-

Model Number:

-

ES027

-

Size:

-

36-48

-

Toe cap:

-

iron toe

-

MOQ:

-

100 Pairs

-

Material:

-

flying knit fabric

-

outsole:

-

rubber cement outsole

-

Function:

-

Anti-slip Anti-puncture Antistatic

-

Insole:

-

EVA Coated Air Mesh

-

Logo:

-

Custom Logo Accepted

-

Delivery Time:

-

30-45days

-

Certification:

-

CE EN SIO 20345:2011

Quick Details

-

Lining Material:

-

Mesh

-

Gender:

-

Unisex

-

Upper Material:

-

None-Woven

-

Outsole Material:

-

EVA

-

Feature:

-

Breathable

-

Toe Style:

-

Iron toe

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ENTE SAFETY

-

Model Number:

-

ES027

-

Size:

-

36-48

-

Toe cap:

-

iron toe

-

MOQ:

-

100 Pairs

-

Material:

-

flying knit fabric

-

outsole:

-

rubber cement outsole

-

Function:

-

Anti-slip Anti-puncture Antistatic

-

Insole:

-

EVA Coated Air Mesh

-

Logo:

-

Custom Logo Accepted

-

Delivery Time:

-

30-45days

-

Certification:

-

CE EN SIO 20345:2011

Product Details

Suede leather+3D mesh

EVA cement Outsole

Reflective Stripe

Features

* Safety shoes act as a barrier against heat, chemicals, oils, shocks and harmful acids.

* These shoes are lightweight and not heavy. The soles are well padded and hence they provide a good amount of comfort to the

wearers, decreasing their fatigue level.

* Safety Shoes inlined with moisture retention materials that help in keeping the feet dry and warm.

* The inclusion of tough material in the shoe composition makes the shoes more durable and sturdy.

* These shoes are lightweight and not heavy. The soles are well padded and hence they provide a good amount of comfort to the

wearers, decreasing their fatigue level.

* Safety Shoes inlined with moisture retention materials that help in keeping the feet dry and warm.

* The inclusion of tough material in the shoe composition makes the shoes more durable and sturdy.

Product packaging

Custom packaging box

Production Process

Cutting of the leather

A hydraulic press cuts the leather with a blade (which is called die). A different die is needed for each piece of the future shoe, and for each size.

Sewing

The die-cut pieces of leather are later sewn accurately with the aid of big and strong sewing machines.

Bonding and attaching

With a special rivet gun metal hooks and eyelets are attached to the shoe.

Shaping

During which the upper of the shoe receives its shape, thanks to the use of a wooden or plastic foot (called a shoetree), after which the sole can be attached to the upper.

Production of the sole

The sole must go through several steps of processing before it can be attached to the other parts of the safety footwear, with the use of a pneumatic press.

Removal of the shoetree

At this stage the shoetree, which gave the upper its form, is removed.

Hot Searches