- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2000*1500*1800mm

-

Year:

-

2024

-

Power (kW):

-

5.5 kW

-

Weight (KG):

-

5500 KG

-

Applicable Industries:

-

Rubber machinery

-

Name:

-

Rubber vulcanizing press machine

-

Plate:

-

#45 steel

-

Basement:

-

welding

-

Hydraulic brand:

-

seven ocean

-

Control:

-

PLC

-

Electric part:

-

CHNT ,SCHNDIDER etc

-

Heating:

-

Electricity ,steam ,or oil

-

Weight:

-

1t-22t

-

Plate size:

-

Optional

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

OULI

-

Voltage:

-

Required, 240-320V

-

Dimension(L*W*H):

-

2000*1500*1800mm

-

Year:

-

2024

-

Power (kW):

-

5.5 kW

-

Weight (KG):

-

5500 KG

-

Applicable Industries:

-

Rubber machinery

-

Name:

-

Rubber vulcanizing press machine

-

Plate:

-

#45 steel

-

Basement:

-

welding

-

Hydraulic brand:

-

seven ocean

-

Control:

-

PLC

-

Electric part:

-

CHNT ,SCHNDIDER etc

-

Heating:

-

Electricity ,steam ,or oil

-

Weight:

-

1t-22t

-

Plate size:

-

Optional

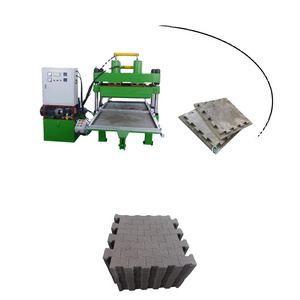

1 Products Description

Rubber flooring tiles product line is one type of environmental type rubber machine , it is used to process the waste tire rubber granules to be different types of rubber flooring tiles by vulcanizing and solidifying .

Meanwhile , it can also process the PU granules , EPDM granules and nature rubber to be tiles . Generally we can customize the machine according customer need.

Meanwhile , it can also process the PU granules , EPDM granules and nature rubber to be tiles . Generally we can customize the machine according customer need.

|

Parameter/model

|

|

XLB-D 550x550x4

|

XLB-D 1100x1100x1

|

XLB-D 1100x1100x2

|

|

|

Structure

|

|

Column

|

Column

|

Frame

|

|

|

Plate size (mm)

|

|

550x550

|

1100x1100

|

1100x1100

|

|

|

Plate QTY

|

|

5

|

2

|

3

|

|

|

Working layer

|

|

4

|

1

|

2

|

|

|

Motor power(kw)

|

|

3

|

5.5

|

5.5

|

|

|

Heating power(kw)

|

|

18

|

26.4

|

39.6

|

|

|

Plate distance (mm)

|

|

200

|

200

|

200

|

|

|

Piston stroke (mm)

|

|

600

|

200

|

400

|

|

|

Size (mm) |

Length

|

800

|

1300

|

1600

|

|

|

|

Width

|

1600

|

3300

|

3300

|

|

|

|

Height

|

1900

|

1800

|

3000

|

|

|

Weight (KG)

|

|

2000

|

5000

|

8000

|

|

2 Our Advantages

3 Manufacturing Technique

4 Recommend Products

Hot Searches