- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZOOMJO

-

Dimension(L*W*H):

-

Customizable

-

Weight:

-

10000 KG

-

Marketing Type:

-

New Product 2023

-

Product Name:

-

Sand Making Machines

-

Color:

-

Customers' Requirements

-

After Sale Service:

-

Engineer Overseas Service

-

Price:

-

Competetive (Can Negotiate)

-

Factory:

-

50,000 Square Meters Closed Workshops

-

Installation and Trial:

-

We Can Send Engineer for Guidance

-

Capacity:

-

150-1200t/h

-

Certification:

-

ISO9001 CE, ISO9001:14000

-

Advantage:

-

Timely Delivery and Installation, Fast Technical Support

Quick Details

-

Type:

-

Sand Making Machine

-

Application:

-

Artificial Sand Making, Stone Crushing, Artificial Sand Making

-

Capacity(t/h):

-

150-1200t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZOOMJO

-

Dimension(L*W*H):

-

Customizable

-

Weight:

-

10000 KG

-

Marketing Type:

-

New Product 2023

-

Product Name:

-

Sand Making Machines

-

Color:

-

Customers' Requirements

-

After Sale Service:

-

Engineer Overseas Service

-

Price:

-

Competetive (Can Negotiate)

-

Factory:

-

50,000 Square Meters Closed Workshops

-

Installation and Trial:

-

We Can Send Engineer for Guidance

-

Capacity:

-

150-1200t/h

-

Certification:

-

ISO9001 CE, ISO9001:14000

-

Advantage:

-

Timely Delivery and Installation, Fast Technical Support

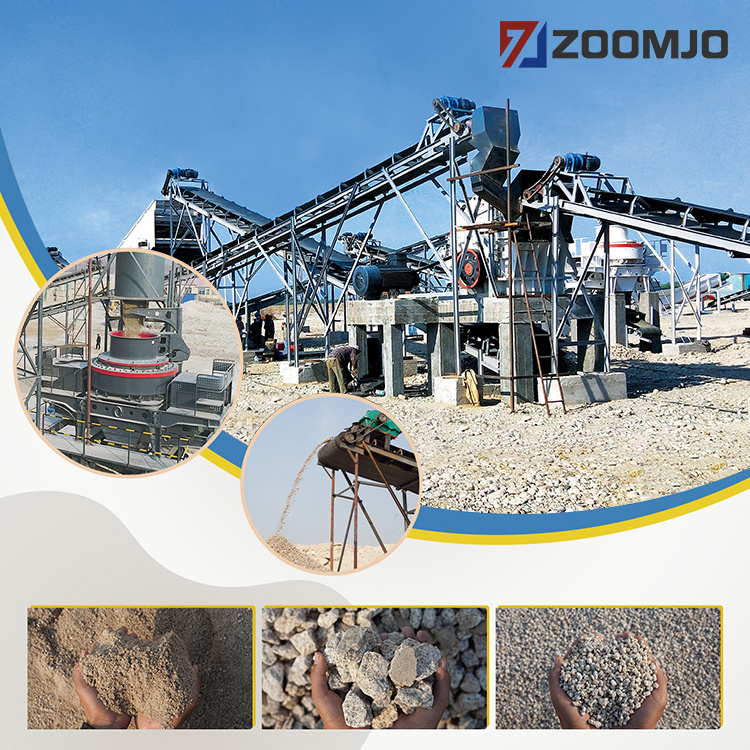

Sand Maker Machine Factory Crushing Fine Sand Crusher Equipment Sand Making Plant Supplier

Product Description

Advantages of Artificial Sand Production

With the optimized design of the deep cavity rotor, the material throughput is increased by about 30%.

The new impeller design of the sand making machine optimizes material flow and the output is as high as 650 t/h.

The machine has the functions of fine crushing and coarse grinding. The product is in the form of a cube, with good particle size and extremely low flake content.

Sand maker is green and environmentally friendly.

Thin-oil lubrication system and automatic maintenance. Under the same capacity, power consumption can be reduced by 10-40%.

Classification

2 Main Types of Sand Makers on the Market

With the development of science and technology and the upgrading of technology, mining machinery has become more and more strict in the selection of crushing equipment. In the continuous research and development and transformation and upgrading, different types of sand making machine appear one after another. The following is the introduction of 5 main types of sand making machine in the market.

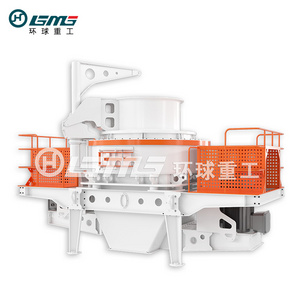

1. Vertical Shaft Impact Crusher

Vertical shaft impact crusher is a new generation of sand making equipment, also known as VSI sand making machine. It has a very high cost performance and is one of the most popular sand making equipment in the market. Vertical Shaft Impact Crusher has

high efficiency, good particle shape

, and dual function of sand making and shaping. Vertical shaft impact crusher adopts deep cavity impeller design, which improves efficiency by 30% and reduces wear by 40%. The sealed chamber design of the sand making machine reduces the impact of dust and noise and realizes environmental protection.

2. Portable Sand Making Machine

Portable sand making machine can be used for single machine production or multiple units for large-scale sand making. Portable sand making machine is divided into wheeled portable sand making machine and crawler portable sand making machine. Wheeled portable sand making machine can be

flexibly transferred and has high production efficiency

, which is suitable for factories with wide material distribution or severe environmental protection situation.

Application

*

Artificial sand making:

processing river pebbles, mountain stones (limestone, granite, basalt, diabase, andesite, etc.), ore tailings, stone chips, and other materials.

* Construction use: construction aggregate, highway road fabric, bedding material, production of asphalt concrete and cement concrete aggregates.

* Engineering use: engineering field of water conservancy and hydropower, high-grade roads, highways, high-speed railroads, passenger dedicated lines, bridges, airport runways, municipal engineering, high-rise construction of the production of mechanism sand and stone shaping.

* Mining industry: fine crushing process in the pre-mill section of the mining industry, material crushing in building materials, metallurgy, chemical industry, mining, refractory materials, cement, grinding materials, and other industries.

* Construction use: construction aggregate, highway road fabric, bedding material, production of asphalt concrete and cement concrete aggregates.

* Engineering use: engineering field of water conservancy and hydropower, high-grade roads, highways, high-speed railroads, passenger dedicated lines, bridges, airport runways, municipal engineering, high-rise construction of the production of mechanism sand and stone shaping.

* Mining industry: fine crushing process in the pre-mill section of the mining industry, material crushing in building materials, metallurgy, chemical industry, mining, refractory materials, cement, grinding materials, and other industries.

Industrial Sand Making Machine Plant

The general production line can be completed by the above three steps, but for the sand with strict requirements on the powder content,

the sand washing machine

can be added after the fine crushing and screening. The common ones in sand production line are circular vibrating screen and linear vibrating screen. Belt conveyor is the hub of sand production line. It has the advantages of low kinetic energy consumption, high production efficiency, large conveying capacity, flexible use, economic and practical.

The sand making equipment can be composed of one sand crusher or combined with several sand crushers.

How to arrange the sand making machinery depends on your needs.

Working Flow

VSI Sand Maker Working Principle

How does VSI Sand Crusher Machine works? Hard stone materials fall into the crusher and are divided into two parts. One part goes into the high-speed-running impeller of the machine, and the other part goes around the impeller.The two parts materials bump and crush fast during the effect of centrifugal force. Then the materials run like swirl, bump and rub to each other again and again. The finished products go out from the bottom of the machine, and users can get the requested products size after screening by vibrating screen. Zoomjo VSI sand maker adopts central feeding and central cascade feeding way, which can be changed based on customers' needs.

Technical Parameter

|

Model

|

|

VSI-7611

|

VSI-8518

|

VSI-9526

|

VSI-1140

|

||||

|

Capacity(t/h)

|

Cascade and Center Feeding

|

120-180

|

200-260

|

300-380

|

450-520

|

||||

|

|

Center Feeding

|

60-90

|

100-130

|

150-190

|

225-260

|

||||

|

Feeder Opening Size (mm)

|

Soft Material

|

≤35

|

≤40

|

≤45

|

≤50

|

||||

|

|

Hard Material

|

≤30

|

≤35

|

≤40

|

≤45

|

||||

|

Rotation Speed

|

|

1700-1890

|

1520-1690

|

1360-1510

|

1180-1310

|

||||

|

Power of the Double Motors(kw)

|

|

110-150

|

180-220

|

264-320

|

400-440

|

||||

|

Overall Dimension(mm)

|

|

3700x2150x2100

|

4140x2280x2425

|

4560x2447x2778

|

5000X2700X3300

|

||||

|

Weight (t)

|

|

7.8

|

10.3

|

16

|

25.6

|

||||

|

Power

|

|

380V:50Hz

|

|

|

|

||||

|

Vibrating Sensor

|

|

Inspection Scope: 0.1-20mm/s,it can be adjusted continuously

|

|

|

|

||||

|

Thin oil lubrication station

|

Power of Double Oil Pump

|

2×0.31kw

|

|

|

|

||||

|

|

Safety

|

supply of oil; Stop automatically without oil flow or oil pressure; Water cooled; Heating start the motor in winter

|

|

|

|

||||

|

|

Overall Dimension (mm)

|

820×520×1270

|

|

|

|

||||

|

|

Power of Oil-box HeaterDimension (kw)

|

2KW

|

|

|

|

||||

If you have any questions about the sand making machine, please leave us a message, we will have a professional pre-sales and after-sales team to serve you!

Customer Cases

Hot Searches