- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

MEIDE

-

Model Number:

-

ASTM B348 GR1 Gr2 TC3 A-1 BT/4 TC4 A-3 BT16

-

Grade:

-

Titanium

-

weight:

-

D*D*3.542*L/1000000

-

Product name:

-

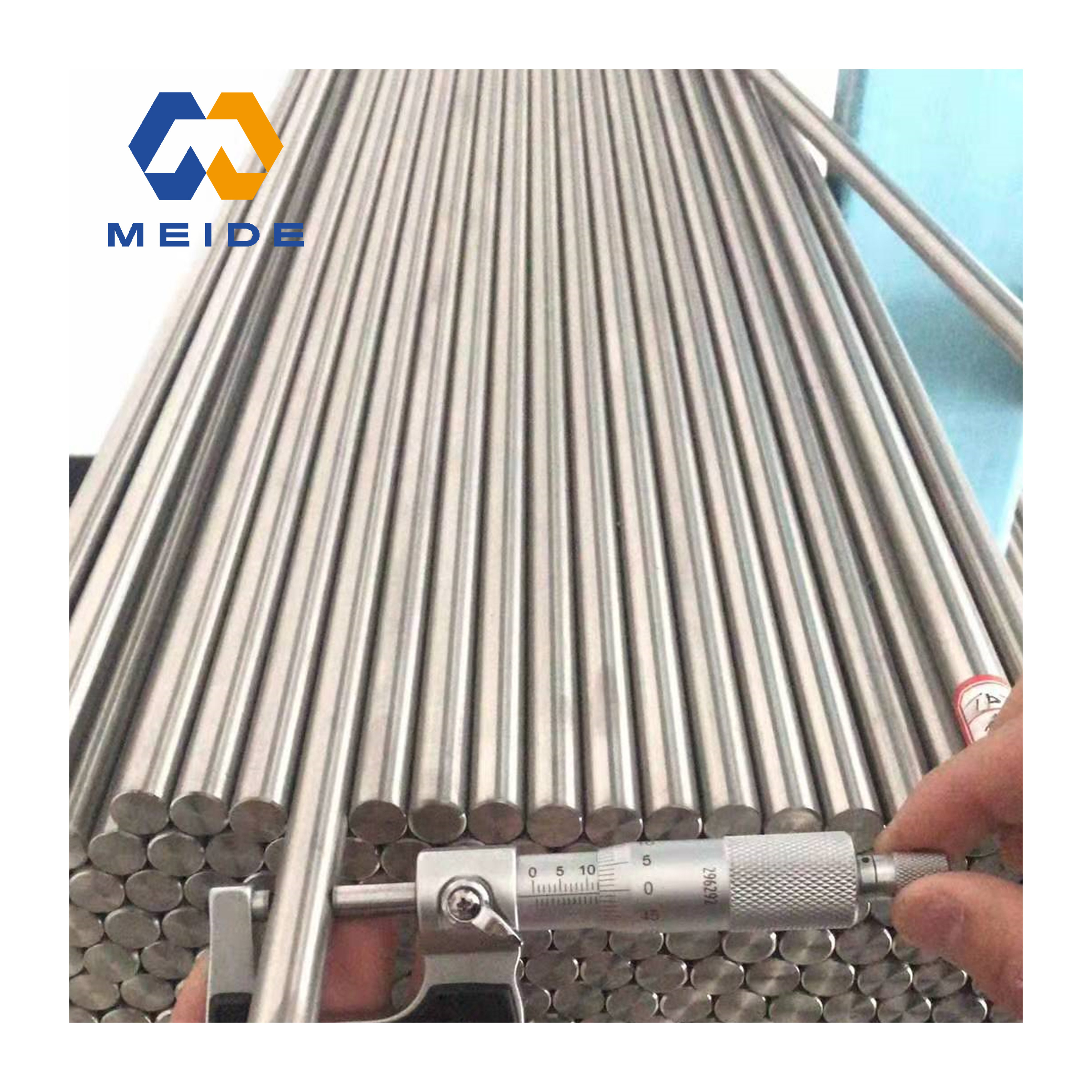

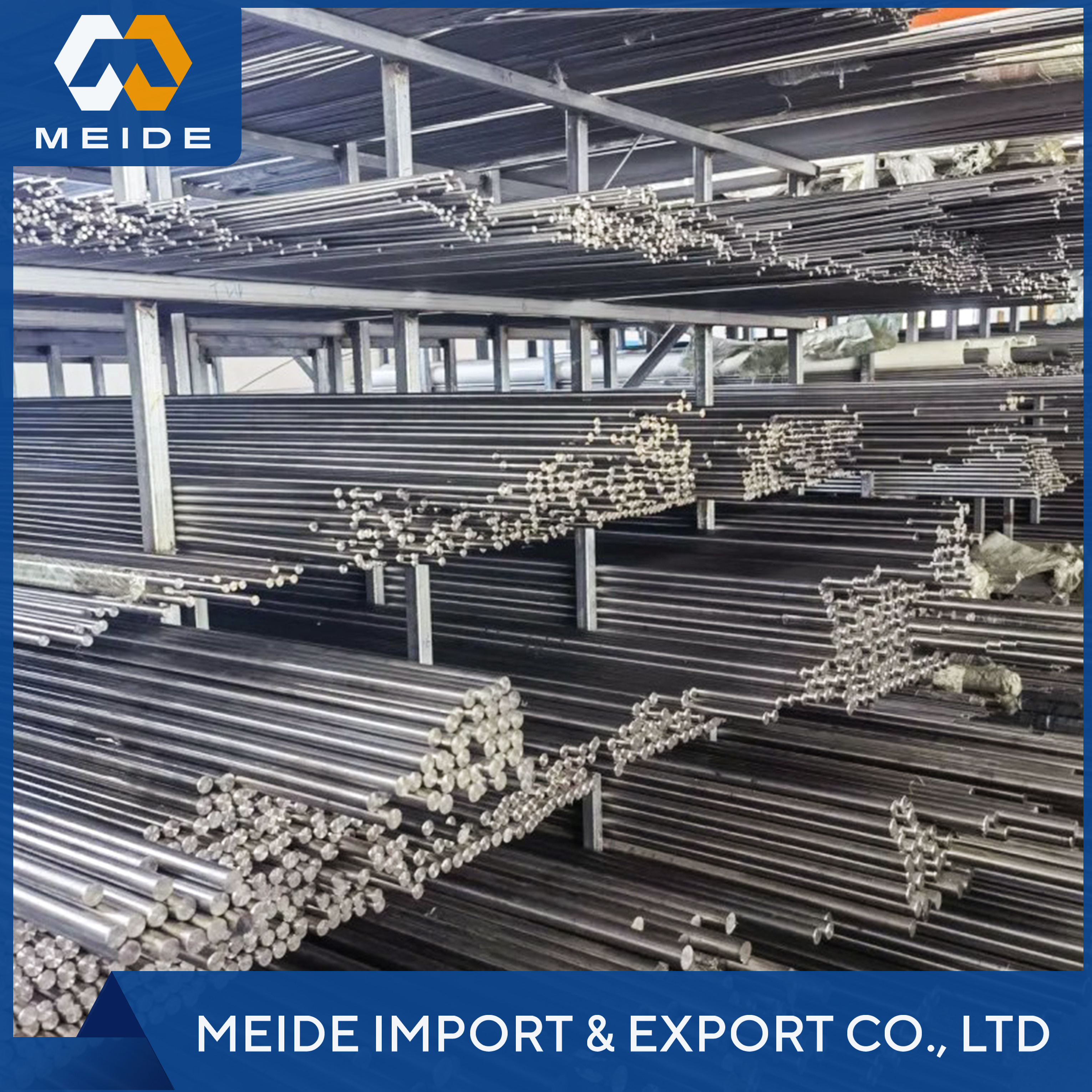

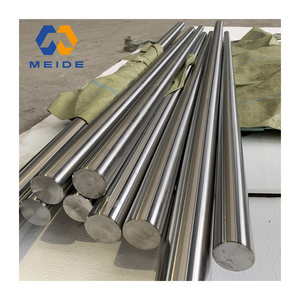

Titanium Alloy Rod/Bar

-

Keyword:

-

Titanium Round Bar/Rod

-

MOQ:

-

10 KG

-

Standard:

-

ASTM B348 ASTM F136

-

Material:

-

Titanium Gr1 Gr2 Gr5 Gr9 Gr10 Gr12

-

Processing:

-

hot rolled,cold rolled,forge,cold drawn

-

Surface:

-

Polished

-

diameter Tolerance1:

-

h6~h13

-

shape:

-

Round, flat, square, hexagonal

-

Advantage:

-

Corrosion Resistance

Quick Details

-

Application:

-

Industry, construction industry, medical industry, etc

-

Length:

-

MAX:6000mm

-

Technique:

-

Rolled

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

MEIDE

-

Model Number:

-

ASTM B348 GR1 Gr2 TC3 A-1 BT/4 TC4 A-3 BT16

-

Grade:

-

Titanium

-

weight:

-

D*D*3.542*L/1000000

-

Product name:

-

Titanium Alloy Rod/Bar

-

Keyword:

-

Titanium Round Bar/Rod

-

MOQ:

-

10 KG

-

Standard:

-

ASTM B348 ASTM F136

-

Material:

-

Titanium Gr1 Gr2 Gr5 Gr9 Gr10 Gr12

-

Processing:

-

hot rolled,cold rolled,forge,cold drawn

-

Surface:

-

Polished

-

diameter Tolerance1:

-

h6~h13

-

shape:

-

Round, flat, square, hexagonal

-

Advantage:

-

Corrosion Resistance

Product Introduction

Titanium round bars and rods

Round bar is made from very small diameters of wire for welding, all the way up to larger diameters (such as the 14″ diameter), used for clutch and flywheels.The medical field often uses small-diameter round bar for body implantable fasteners and dental appliances.

Standard:

ASTM B/SB 348; ASTM B/SB 381,ASTM F136; ASTM F67, AMS4928, ISO5832-2/-3,

Available grades :

Gr1, Gr2, Gr3, GR4, Gr5, Gr7, Gr9, Gr12....GR36

Available sizes:

Diameter :

0.1mm up to -350mm

Length:

20-6000mm for rods and bars, 0.1kgs-100kgs /coll for wires

Titanium square bars and rods

Titanium square bars have the square side. The most popular grade is GR2, GR3, GR4, GR5.

Available sizes:

a: 4mm up to 450mm

b: 50mm up to 6000mm

Popular sizes:

a*a*b 6*6*b 8mm*8mm*b 10mm*10mm*b 12mm*12mm*b 16mm*16mm*b

Grade and Chemical Composition (%) :

|

Grade

|

N(≤)

|

C(≤)

|

H(≤)

|

Fe(≤)

|

O(≤)

|

Al(≤)

|

V(≤)

|

Ni(≤)

|

Ti

|

|

GR1

|

0.03

|

0.08

|

0.015

|

0.2

|

0.18

|

/

|

/

|

/

|

bal

|

|

GR2

|

0.03

|

0.08

|

0.015

|

0.3

|

0.25

|

/

|

/

|

/

|

bal

|

|

GR3

|

0.05

|

0.08

|

0.015

|

0.3

|

0.35

|

/

|

/

|

/

|

bal

|

|

GR4

|

0.05

|

0.08

|

0.015

|

0.2

|

0.4

|

/

|

/

|

/

|

bal

|

|

GR5

|

0.05

|

0.08

|

0.015

|

0.4

|

0.2

|

5.5~6.75

|

3.5~4.5

|

/

|

bal

|

|

GR7

|

0.03

|

0.08

|

0.015

|

0.3

|

0.25

|

/

|

/

|

/

|

bal

|

|

GR9

|

0.03

|

0.08

|

0.015

|

0.25

|

0.15

|

2.5~3.5

|

2.0~3.0

|

/

|

bal

|

|

GR12

|

0.03

|

0.08

|

0.015

|

0.3

|

0.25

|

/

|

/

|

0.6~0.9

|

bal

|

|

GR23

|

0.05

|

0.08

|

0.012

|

0.25

|

0.13

|

5.5~6.5

|

3.5~4.5

|

|

bal

|

Mechanical property

|

Grade

|

Tensil strength(≥)

|

|

Yeild strength(≥))

|

|

Elongation(≥)%)

|

||

|

|

ksi

|

Mpa

|

ksi

|

Mpa

|

|

||

|

GR1

|

35

|

240

|

20

|

138

|

24

|

||

|

GR2

|

50

|

345

|

40

|

275

|

20

|

||

|

GR3

|

65

|

450

|

55

|

380

|

18

|

||

|

GR4

|

80

|

550

|

70

|

483

|

15

|

||

|

GR5

|

130

|

895

|

120

|

828

|

10

|

||

|

GR7

|

50

|

345

|

40

|

275

|

20

|

||

|

GR9

|

90

|

620

|

70

|

483

|

15

|

||

|

GR12

|

70

|

483

|

20

|

345

|

18

|

||

|

GR23

|

120

|

828

|

110

|

760

|

10

|

||

Product specification

|

Grade

|

Produce Type

|

Specification(mm)

|

Standard

|

|

|

Gr1

Gr2 Gr3 Gr4 Gr5 Gr6 Gr7 Gr9 Gr11 Gr12 Gr13 |

Ti round bar

|

Dia 5.0~350 X ≤ 6000

|

ASTM B348

ASTM F67 ASTM F136 AMS 4928 ASTM F1295 MIL-T-9047G ISO-5832-2 ISO-5832-3 Other related standards |

|

|

|

Ti square bar

|

Dia 5.0~350 X ≤ 6000

|

|

|

|

|

Ti flat bar

|

Dia 5.0~350 X ≤ 6000

|

|

|

|

|

Ti hexagnal bar

|

Dia 5.0~350 X ≤ 6000

|

|

|

|

Tolerance

|

h6~h13 H10~H13

|

|

|

|

Product application

A

erospace Applications

Due to their high tensile strength to density ratio, high corrosion resistance, and ability to withstand moderately high

temperatures without creeping, titanium alloys are used in aircraft, armor plating, naval ships, spacecraft, and missiles.

Industrial Applications

Titanium is used in engine applications such as rotors, compressor blades, hydraulic system components and nacelles. Titanium 6AL-4V alloy accounts for almost 50% of all alloys used in aircraft applications.

Consumer and Architectural Applications

Titanium metal is used in automotive applications, particularly in automobile or motorcycle racing, where weight reduction is critical while maintaining high strength and rigidity.

Medical Applications

Due to their high tensile strength to density ratio, high corrosion resistance, and ability to withstand moderately high

temperatures without creeping, titanium alloys are used in aircraft, armor plating, naval ships, spacecraft, and missiles.

Industrial Applications

Titanium is used in engine applications such as rotors, compressor blades, hydraulic system components and nacelles. Titanium 6AL-4V alloy accounts for almost 50% of all alloys used in aircraft applications.

Consumer and Architectural Applications

Titanium metal is used in automotive applications, particularly in automobile or motorcycle racing, where weight reduction is critical while maintaining high strength and rigidity.

Medical Applications

Titanium has the inherent property to osseointegrate, enabling use in dental implants that can remain in place for over 30 years.

FAQ

1.Are you a manufacturer or a trader?

We're a manufacturer with more than years of professional production experience.

2.Can you accept OEM?

Yes, OEM is acceptable. Just pls provide us with the drawing or sample, we will production totally according to your requirements.

3.Can you provide us with the design drawing?

Yeah, of course, we will provide you with the drawing after you paid or prepaid.

4.Can your factory produce products according to our drawings?

Yes, we can. Most products can be customized, including the Logo on products.

5.What kind of your packaging?

Neutral plywood or wooden box packaging or according to customer's requirements.

6.How long is your delivery time?

Normally 30days after payment, and we promise we will deliver as soon as we can.

7.How can we get your price ?

1. We need below information to quote for you:

1). Product Name

2). Standard

3). Material Grade (Chemical Composition)

4). Dimension

5). Quantity

6). The Drawing for Special Parts

We're a manufacturer with more than years of professional production experience.

2.Can you accept OEM?

Yes, OEM is acceptable. Just pls provide us with the drawing or sample, we will production totally according to your requirements.

3.Can you provide us with the design drawing?

Yeah, of course, we will provide you with the drawing after you paid or prepaid.

4.Can your factory produce products according to our drawings?

Yes, we can. Most products can be customized, including the Logo on products.

5.What kind of your packaging?

Neutral plywood or wooden box packaging or according to customer's requirements.

6.How long is your delivery time?

Normally 30days after payment, and we promise we will deliver as soon as we can.

7.How can we get your price ?

1. We need below information to quote for you:

1). Product Name

2). Standard

3). Material Grade (Chemical Composition)

4). Dimension

5). Quantity

6). The Drawing for Special Parts

Hot Searches