- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Gomine

-

Dimension(L*W*H):

-

190*160*180cm

-

Name:

-

Briquettes Making Machine

-

Size:

-

Depend on model

-

Voltage:

-

110V/220V/380V/Customized 1Phase

-

Color:

-

Customer's Request

-

Input Materials:

-

Aluminum powder, coal powder, mineral powder, ore powder, etc.

-

Application:

-

Fuel, BBQ

-

Briquette shape:

-

Round, Square, Pillow

-

Working Theory:

-

Pressure Roller

-

Roller diameter:

-

360mm

-

After Warranty Service:

-

Video technical support

Quick Details

-

Weight (KG):

-

8000

-

Production Capacity:

-

1-50 t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Gomine

-

Dimension(L*W*H):

-

190*160*180cm

-

Name:

-

Briquettes Making Machine

-

Size:

-

Depend on model

-

Voltage:

-

110V/220V/380V/Customized 1Phase

-

Color:

-

Customer's Request

-

Input Materials:

-

Aluminum powder, coal powder, mineral powder, ore powder, etc.

-

Application:

-

Fuel, BBQ

-

Briquette shape:

-

Round, Square, Pillow

-

Working Theory:

-

Pressure Roller

-

Roller diameter:

-

360mm

-

After Warranty Service:

-

Video technical support

High quality new design metal chip briquetting machine/Ball Press Machine

Products Description

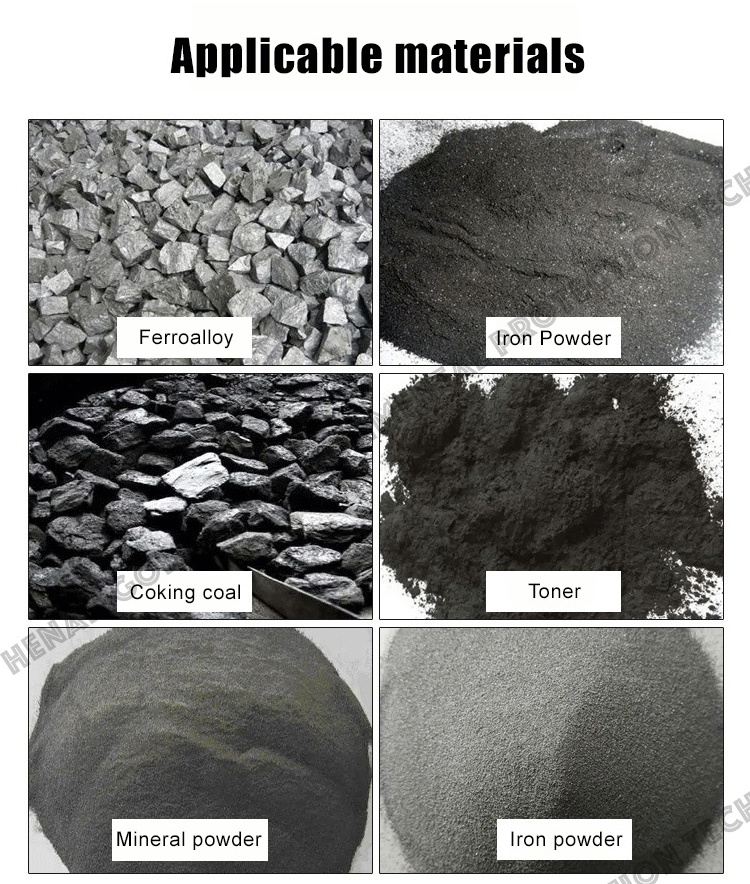

Raw materials of roller type ball press machine:

Roller type briquette making ball press machine is a widely used in many range, our machine can press briquettes from coal fines, anthracite coal, bituminous coal, subbituminous coal, coke fines, carbon powder, charcoal powder, carbon black, iron ore fines, mineral powder, metal dust, iron dust, mill scale, manganese ore fines, fluorite powder, gypsum powder, chemical salt, ferrosilicon powder, nickel alloy, blast furnace ash, converter dust, MgO, graphite, oil shale, potash fertilizer, urea fertilizer, sea sand powder etc.

|

Model

|

Roller Diameter (mm)

|

Capacity (t/h)

|

Power (kw)

|

Reducer

|

|

GM-290

|

290

|

1-2.5

|

5.5-7.5

|

350

|

|

GM-360

|

360

|

3-5

|

7.5-11

|

350

|

|

GM-430

|

430

|

5-8

|

15

|

500

|

|

GM-500

|

500

|

8-11

|

30

|

650

|

|

GM-650

|

650

|

10-15

|

37-45

|

750

|

|

GM-750

|

750

|

20-25

|

45

|

750

|

|

GM-850

|

850

|

20-28

|

55

|

850

|

|

GM-1000

|

1000

|

23-35

|

90

|

1000

|

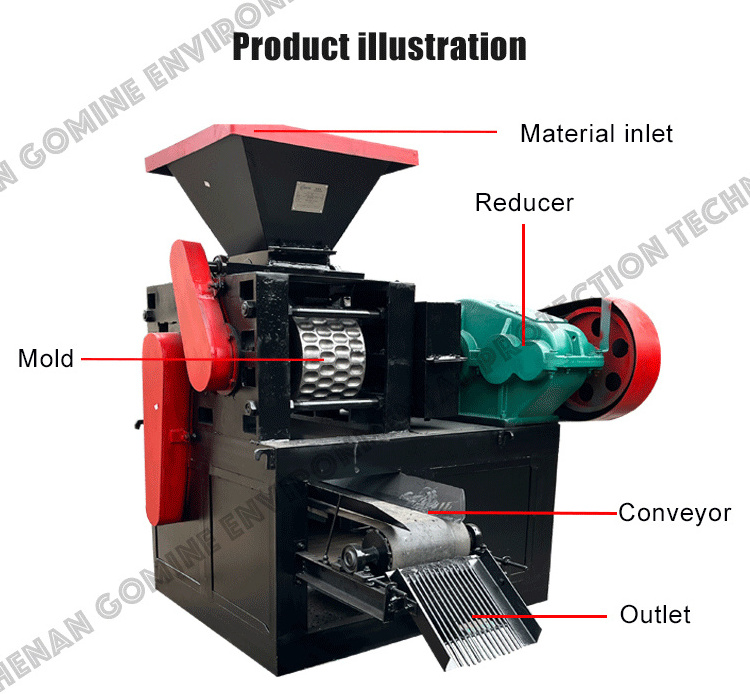

Roller type ball press machine

is made up of three parts: feeding, driving and briquetting.

1. Feed section

: To make sure materials enter double rollers evenly by feeding in ration. Driven by the electromagnetic speed regulating motor and after the belt wheel and worm reducer turn, the spiral feed device of briquette machines presses materials into the main feed port. As the constant matrix feature of the electromagnetic speed regulating motor, when the spiral feeder has the same pressing quantity with the inventory of the main body of the briquetting machine or briquettes machine, the feeding pressure will stay constant thus stabilizing the balling quality. If there is a large feed amount, the electricity of the feeding device will be overloaded and vice versa. Therefore, it's very important to operate the machine skillfully.

2. Driving section

: The driving system consists of electromotor, triangle section, reducer, open gear and rollers. The briquetting machine runs relying on the cooperation of driving and driven shaft supported by the exposed gear. It is driven by the electromagnetic speed regulating motor; after the belt wheel and cylindrical gear reducer, the power is transferred to the pin coupling shaft. Hydraulic pressure device is installed on the back of the driven shaft block. The hydraulic protection device of briquette machine can make axial displacement of the piston as the hydraulic pump pushes the high pressure oil into the hydraulic tank. The front connecting end of the piston supports the bearing pedestal to meet the production requirement.

3. Briquetting section

: Referring to the main body of the briquetting machine or briquette machine with the rollers as its core working part. When too many materials or metal blocks enter the space between the two compression rollers, the piston rod of the hydraulic cylinder gets so pressed that the pump will stop working and the energy accumulator will make buffer action facing pressure changing. Then the flood valve starts the oil return and the piston rod replacement will widen the space between the rollers thus forcing hard materials to pass the rollers. Finally, the whole pressure system of briquette machine or briquette press machine returns to normal condition so that the rollers won't be damaged.

Packaging & Shipping

Hot Searches