- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Base on configuration

-

Dimension(L*W*H):

-

According to configuration

-

Weight:

-

5000

-

Capacity:

-

100-250kg/h

-

Core production technology:

-

Extrusion

-

Extruder type:

-

Single screw extruder or twin-screw extruder

-

Extruder material:

-

38CrMoAl

-

Inverters brand:

-

Delta/LS/ABB/Siemens

-

Straws main material:

-

Rice flour, tapioca flour

-

Cutting type:

-

Rolling cutting or guillotine cutting

-

Worker quantoty:

-

1 worker

-

Automation degree:

-

Full-automatic

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SHENGRUN

-

Voltage:

-

208/220/380/400/415/440V

-

Power:

-

Base on configuration

-

Dimension(L*W*H):

-

According to configuration

-

Weight:

-

5000

-

Capacity:

-

100-250kg/h

-

Core production technology:

-

Extrusion

-

Extruder type:

-

Single screw extruder or twin-screw extruder

-

Extruder material:

-

38CrMoAl

-

Inverters brand:

-

Delta/LS/ABB/Siemens

-

Straws main material:

-

Rice flour, tapioca flour

-

Cutting type:

-

Rolling cutting or guillotine cutting

-

Worker quantoty:

-

1 worker

-

Automation degree:

-

Full-automatic

High-capacity edible and biodegradable rice powder and cornstarch materials rice straw making machine price

1. Biodegradable rice drinking straw processing line introduction

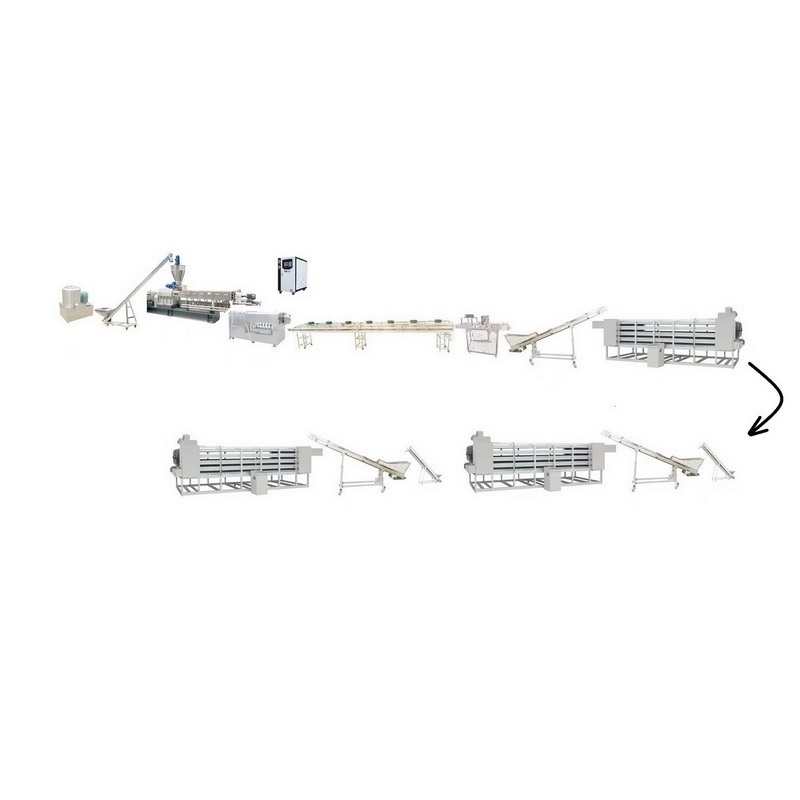

Biodegradable rice dinking straw processing line is used for making biodegradable dinking straws. This straw is a new product, which is eco-friendly. Its degradation time is much shorter than traditional plastic straws. This line is made up with raw materials treatment machines, single screw or twin-screw extruder, cooling conveyer and cutting machine.

2. Biodegradable rice drinking straw processing line description:

2.1 Flow chart: raw materials→ extrusion → cooling → cutting

2.2 Biodegradable rice drinking straw processing line features:

2.2.1 High work efficiency, automation degree.

2.2.2 Low land occupation, power consumption, labor cost, waste rate.

2.2.3 Various configurations and capacity choices.

2.2.4 Various finished products sizes.

2.2.5 P roduction factors can be quantified and controlled.

2.2.6 World-class food grade fittings.

2.2.7 A ll machines and fittings can be custom-made. ODM or OEM is available.

2.2.8 P rofessional pre-sale, sale and after-sale service.

2.2.9 Equipped with inverters to control speed.

2.3 Biodegradable rice drinking straw processing line parameters

|

Model |

Capacity (kg/h) |

Installed

|

Actual

|

|

|

EXT100-RS |

100-150 |

53 |

29 |

|

|

TSE75-RS |

200-250 |

66 |

52 |

2.4 Biodegradable rice drinking straw processing line machines and fittings graphic introduction

2.4.1 Series extruders

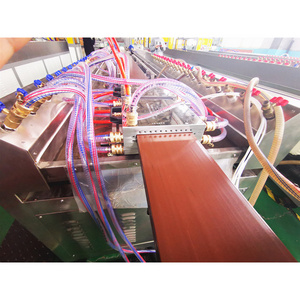

2.4.2 Fittings

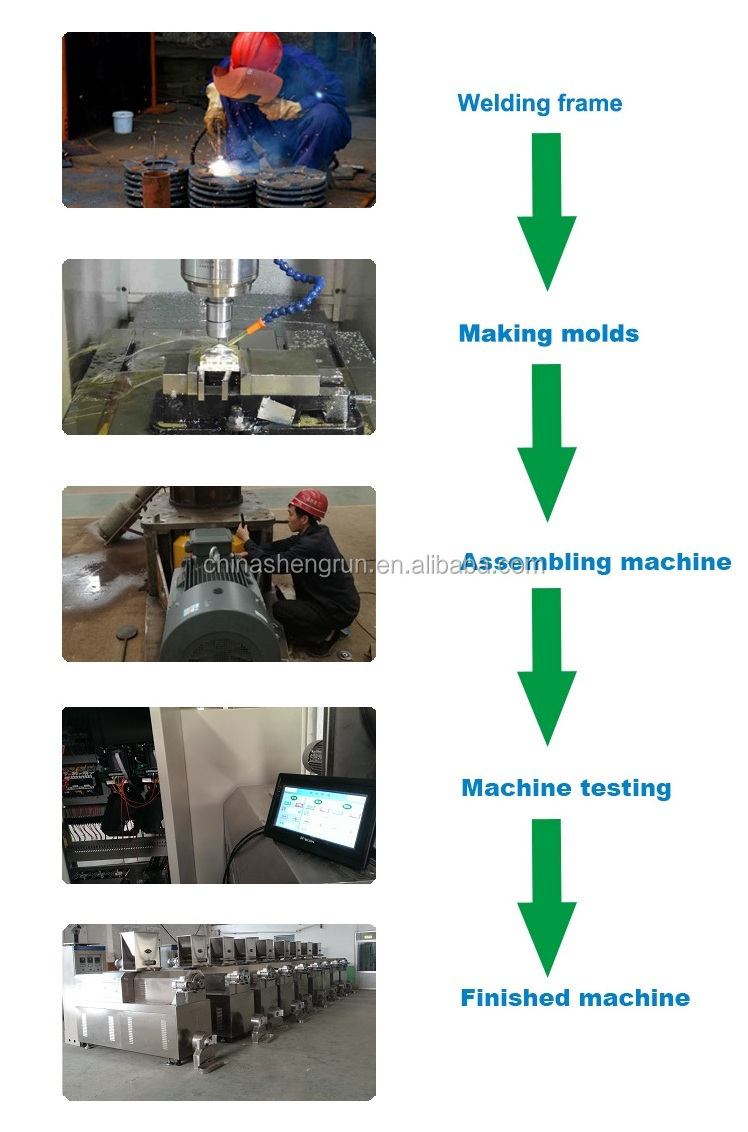

2.5 Biodegradable rice drinking straw processing line manufacture process

3. Biodegradable rice drinking straw introduction

Billions of plastic products are used every day. They are convenient and low-cost. But the pollution cased by them is more obvious. Most plastic products need several decades to be degraded, which is even longer than human longevity. This problem seriously influences on country economy, people's lives and environmental protection. Thanks to science and technology development, this problem is alleviated greatly by biodegradable products made from food or other materials.

Biodegradable rice drinking straw is one kind of products, which is made from rice powder and tapioca powder. Its core production technique is modern extrusion technology. Because the raw materials are food, this straw is safe and pollution-free. This drinking straw will be decomposed within 100 days after using. Consumers can even eat it, which has a little rice flavor.

4. Packing and delivery

4.1 Inside package is plastic film, outside package is wooden/plywood cases, which is seaworthy.

4.2 We can supply fumigation package and certificate.

5. Service

5.1 1 year warranty period.

5.2 Supply free fittings and general tool.

5.3 Engineers available to service machinery overseas.

5.4 Supply formula of raw materials.

5.5 Workshop design suggestion.