- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Ling Feng

-

Model Number:

-

200*600

-

Voltage:

-

380 v

-

Power:

-

10.5 kw

-

Dimension(L*W*H):

-

2.5*1.15*1 m

-

Weight:

-

2.5 t

-

Features:

-

high-density structure

-

Warranty:

-

one year

-

Certification:

-

Utility model patent certificate

-

color:

-

yellow or custom

-

use 1:

-

hollow core slab machine

-

use 2:

-

precast slab machine

-

Holes:

-

4

-

Alloy Thickness:

-

1.5 mm

-

OEM:

-

available

-

Business Scope:

-

Worldwide

-

Shape of hole:

-

circle

-

Raw material:

-

cement stone sand

-

Diameter of hole:

-

76mm

Quick Details

-

Application:

-

Build houses

-

Production Capacity:

-

60~65m/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Ling Feng

-

Model Number:

-

200*600

-

Voltage:

-

380 v

-

Power:

-

10.5 kw

-

Dimension(L*W*H):

-

2.5*1.15*1 m

-

Weight:

-

2.5 t

-

Features:

-

high-density structure

-

Warranty:

-

one year

-

Certification:

-

Utility model patent certificate

-

color:

-

yellow or custom

-

use 1:

-

hollow core slab machine

-

use 2:

-

precast slab machine

-

Holes:

-

4

-

Alloy Thickness:

-

1.5 mm

-

OEM:

-

available

-

Business Scope:

-

Worldwide

-

Shape of hole:

-

circle

-

Raw material:

-

cement stone sand

-

Diameter of hole:

-

76mm

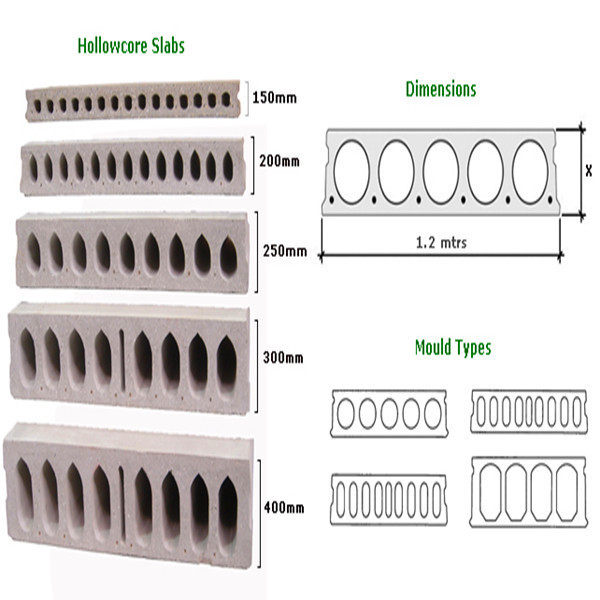

200*600 concrete hollow core slab forming/making machine for sale

Cement hollow core slab making machine works on the long-line table, using the high-strength low-relaxation steel strand as the guide, using the pushing work method to forming the concrete hollow-core slab. The slab have the advantages of smooth surface, high-density structure, The concrete hollow-core slab mainly used on the larger bay workshop, school, hospital, shopping mall, office building, bulk storage plant etc.

Introduction of precast prepressed concrete slab machine-

1.Materials mixing system

2.Prestressing system,(straighten the steel strand in the precast concrete slabs)

3.Materials transport, (by concrete dumper tricycle)

4.Precast prestressed concrete slab machine (concrete slab machine working system)

5.Concrete slab cutting system. (by concrete slab cutting machine)

Production Process of the precast prestressed concrete slabs production line-

Strengths of the precast prestressed concrete slabs-

1. Advanced and matured technology of the precast prestressed concrete slab production line

2.Fast molding speed of the precast prestressed concrete slab machine:1.2-1.4m/min

3.Low labor strength and high efficiency of the precast prestressed concrete slab production line

4.Long service life for the precast prestressed concrete slab machines

Slabs Machine-

|

Model |

Power ( kw ) |

Dimension ( m ) |

Holes |

Voltage (v) |

Strand with maximum load |

Speed (m/h) |

Weight (t) |

|

200*600 |

10.5 |

2.3*1* 0.9 |

4 |

380 |

12.7mm*5 |

65~70m/h |

2.3 |

|

200*900 |

15 |

2.7*1.15*1 |

5 |

380 |

12.7mm*7 |

60~65m/h |

4 |

|

250*900 |

18.5 |

3.8*1.15*1 |

5 |

380 |

12.7mm*7 |

60~65m/h |

4.5 |

|

150*900 |

15 |

2.6*1.6*1 |

9 |

380 |

12.7mm*12 |

65~70m/h |

3.8 |

|

300*900 |

22 |

3.36*1.15*1.2 |

5 |

380 |

12.7mm*6 |

60~65m/h |

5.5 |

|

300*1200 |

36 |

3.5*1.85*1.2 |

6 |

380 |

12.7mm*12 |

60~65m/h |

6 |

|

150*1200 |

18.5 |

2.9*1.5*1 |

13 |

380 |

9.5mm*14 |

65~70m/h |

3.3 |

|

180*1200 |

18.5 |

2.9*1.5*1.2 |

11 |

380 |

12.7mm*12 |

60~70m/h |

3.3 |

|

200*1200 |

22 |

3.7*1.5*1.5 |

10 |

380 |

12.7mm*10 |

65~70m/h |

5.3 |

|

250*1200 |

33 |

3.7*1.7*1.5 |

8 |

380 |

12.7mm*10 |

60~65m/h |

6.2 |

Load and span of precast prestressed concrete slabs-

|

Slab size (Thickness x Width)(mm) |

Max. length (m) |

Max. load (Kn/m 2 ) |

Dia. of steel when max. load (mm) |

No. of steel when max. load |

Holes No. |

|

100x600 |

5.1 |

8.11 |

Φ7 |

5 |

6 |

|

120x600 |

6.0 |

8.86 |

Φ7 |

6 |

5 |

|

150x600 |

7.5 |

10.24 |

Φ9.5 |

5 |

4 |

|

180x600 |

9.0 |

16.16 |

Φ12.7 |

4 |

3 |

|

100x900 |

5.1 |

9.76 |

Φ7 |

10 |

10 |

|

120x900 |

6.0 |

8.86 |

Φ7 |

9 |

8 |

|

150x900 |

7.5 |

10.24 |

Φ9.5 |

10 |

6 |

|

180x900 |

9.0 |

16.16 |

Φ12.7 |

9 |

5 |

|

200x900 |

10.2 |

13.22 |

Φ12.7 |

7 |

6 |

|

250x900 |

12.6 |

11.10 |

Φ12.7 |

7 |

6 |

|

300x900 |

15 |

10.83 |

Φ12.7 |

8 |

5 |

1. Wear-resistant alloy

2.High cost high strength high quality steel plate

3.The best Vibrator and Reducer

4.Professional welding workers

Our services:

We have customers all over the world, such as Egypt , Malaysia , Dubai , Uzbekistan,Myanmar, etc. Not only we offer the high quality products, also the best after-sale service.

1. Pre-sale service of concrete hollow core slab

--- Learn customer’s demands and introduce the best suitable products to you

---Technical service to customer before installation

2. During sale service of concrete hollow core slab

---Supervise whole process of production to make sure customer will get our product on time

---Offer the necessary technical details to customer