- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

LS

-

Model Number:

-

LS-AN-112A1

-

Product Name:

-

Custom Conductive Foam

-

Fabric:

-

Nickel/Copper Plated

-

Adhesive:

-

Conductive Adhesive

-

Foam Color:

-

Black/Silver

-

Custom Service:

-

Size/Shape/Adhesive/Material

-

Shape:

-

Custom Shape

-

Thickness:

-

0.5MM~20MM/Custom

-

Surface Resistivity:

-

>0.2Ω/Sq

-

Shielding Effectiveness:

-

100Mhz - 1GHz

-

Certification:

-

ISO9001:2015

Quick Details

-

Material:

-

PU/PE

-

Type:

-

Foam

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LS

-

Model Number:

-

LS-AN-112A1

-

Product Name:

-

Custom Conductive Foam

-

Fabric:

-

Nickel/Copper Plated

-

Adhesive:

-

Conductive Adhesive

-

Foam Color:

-

Black/Silver

-

Custom Service:

-

Size/Shape/Adhesive/Material

-

Shape:

-

Custom Shape

-

Thickness:

-

0.5MM~20MM/Custom

-

Surface Resistivity:

-

>0.2Ω/Sq

-

Shielding Effectiveness:

-

100Mhz - 1GHz

-

Certification:

-

ISO9001:2015

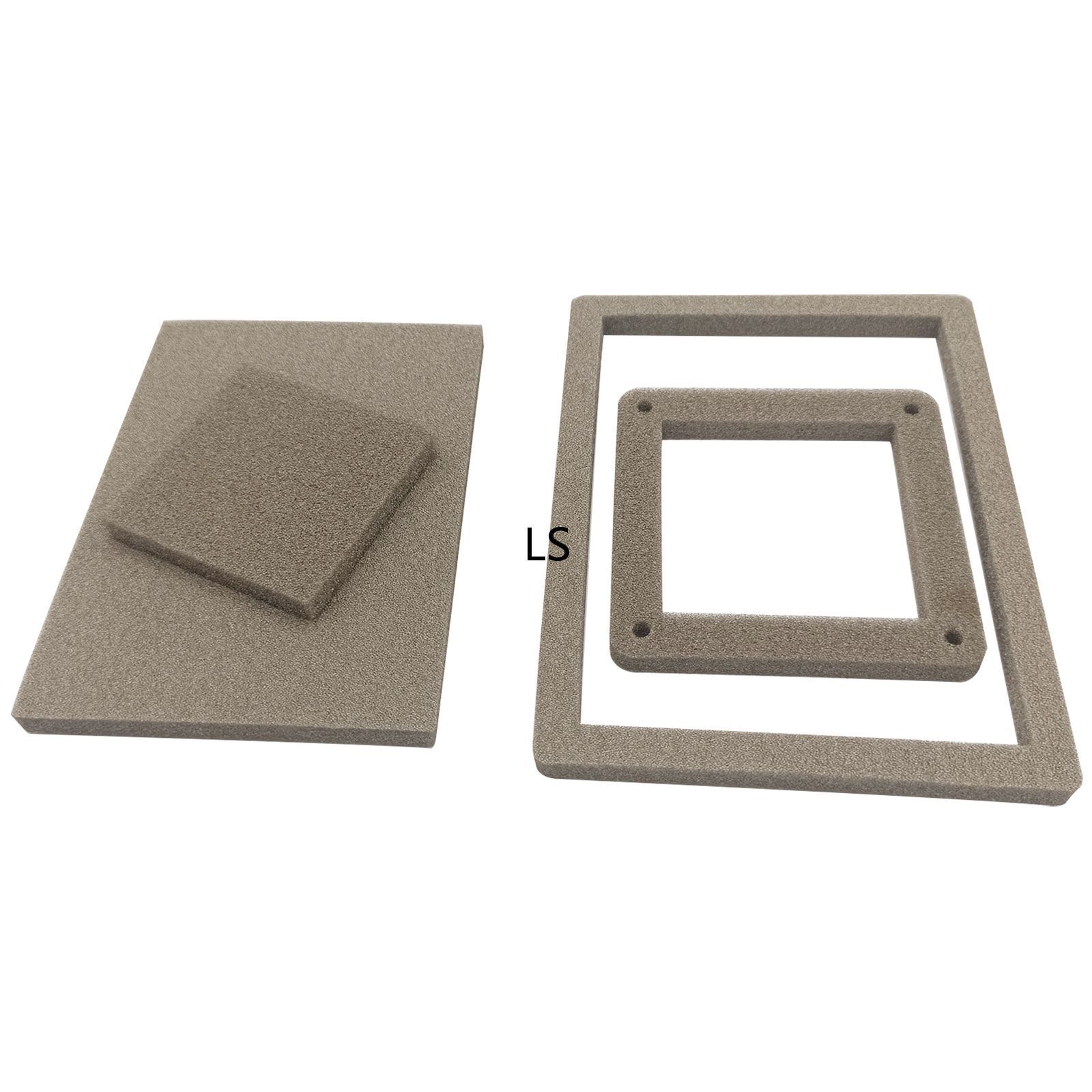

*

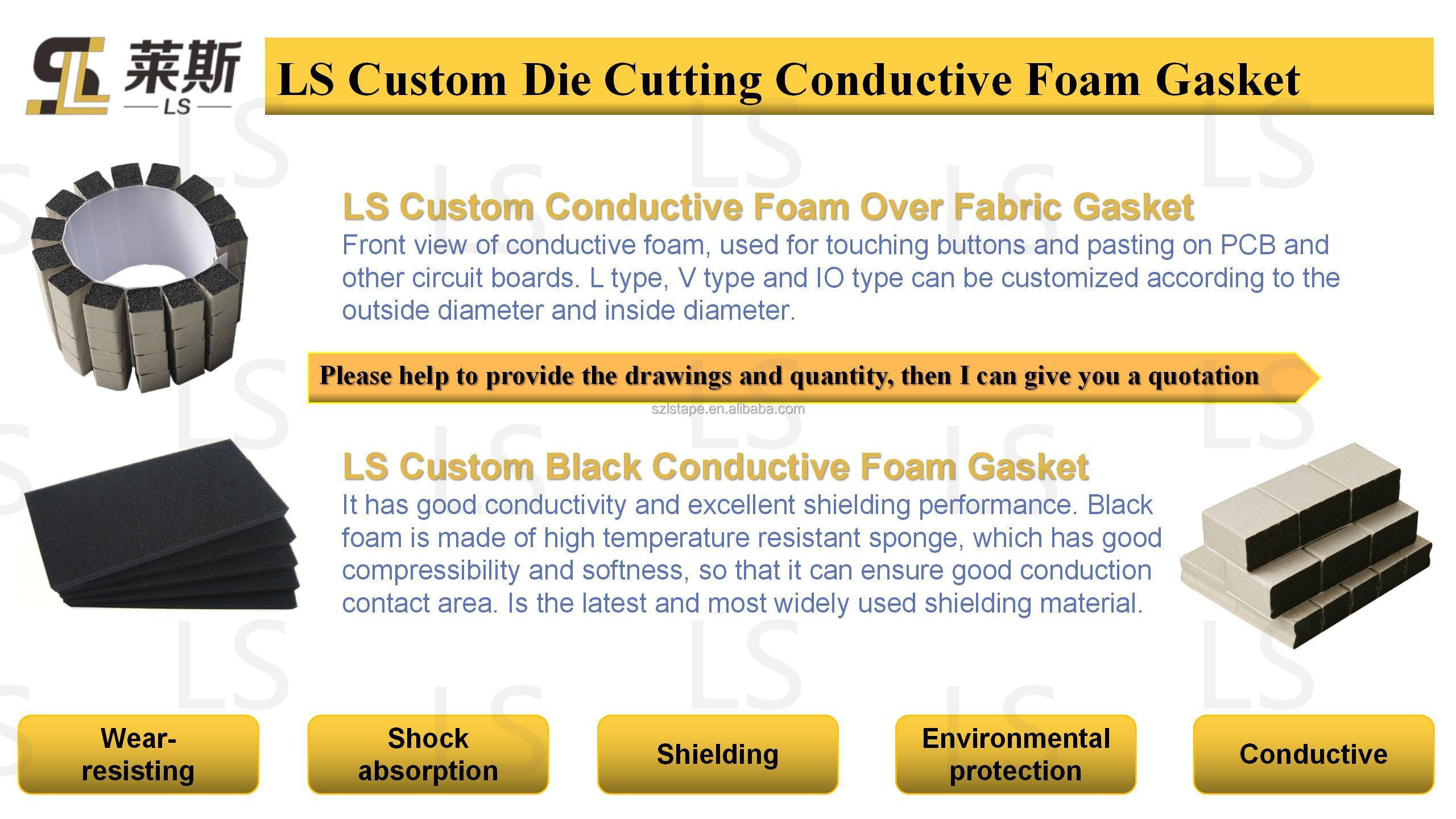

C

onductive

F

oam

It is a cost-effective gap shielding material, which is made of conductive cloth with high conductivity and corrosion resistance and coated with low-pressure foam. It is made of precision machining, widely used in gaps of chassis and other equipment as well as EMI/EMC prevention of various electronic products.

It provides impedance conductive connection and has good electromagnetic wave shielding effect.

#

Please check the structure diagram of conductive foam picture

#

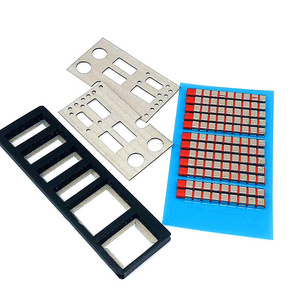

|

Product Type 1

|

Conductive naked foam

|

|

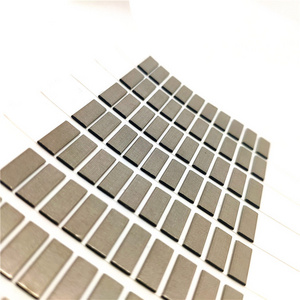

Product Type 2

|

Conductive foam with conductive adhesive

|

|

||

|

Product Type 3

|

Conductive copper foam

|

|

Product Type 4

|

Nickel plated copper conductive foam

|

|

||

|

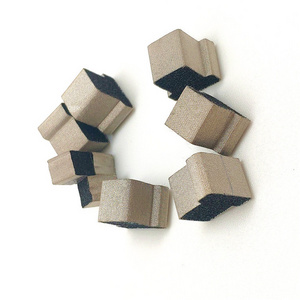

Product Type 5

|

Tinned conductive foam

|

|

Product Type 6

|

Omnidirectional conductive foam

|

|

||

|

Product Type 7

|

SMT conductive foam

|

|

Product Type 8

|

Carbon-plated conductive foam

|

|

||

|

Product Type 9

|

EMI conductive foam

|

|

Product Type 10

|

Gold-plated conductive foam

|

|

||

|

EMI Conductive Foam Gasket

|

|

|

|

|||

|

Item

|

Unit

|

Value

|

Test Method

|

|||

|

Shielding Effectiveness

|

dB

|

≥75

|

ASTM D4935-99

|

|||

|

Salt Spray

(5%, 24H, 35Degree C)

|

Grade

|

≥4

|

ASTM F390

|

|||

|

Abrasion Test

|

Time

|

≥1,000,000

|

ASTM B117-03

|

|||

|

Surface Resistivity

|

Ω/sq

|

≤0.05

|

ASTM F390

|

|||

|

Metal Adhesion

|

Grade

|

≥4

|

AATCC TM8-2001

|

|||

|

Conductivity in-Z Directions resistance

|

Ω

|

≤0.05

|

/

|

|||

|

Tensile Strength

|

1bf

|

≥67

|

|

|||

|

Tensile MPa

|

1bf

|

≥52

|

|

|||

|

LS Conductive Foam Gasket

|

|

|

|

|

|

|

|

|||||||

|

P/N

|

LS1

|

LS2

|

LS3

|

LS4

|

LS5

|

LS6

|

Test

|

|||||||

|

Color

|

Grey/Black

|

Grey/Black

|

Grey

|

Grey/Black

|

Grey

|

Grey/Black

|

Visual

|

|||||||

|

T(mm)

|

0.3

|

0.5

|

0.8

|

1.0

|

1.5/2.0/2.5/3.0/3.5

|

4.0

|

Standards

|

|||||||

|

Tolerance

|

±0.15mm

|

|

|

|

±0.3mm (T≥5mm,±0.5mm)

|

|

Standards

|

|||||||

|

Peel

Strength

|

≥800

|

|

|

|

≥1200

|

|

ASTMD

1000

|

|||||||

|

Contact Resistance

|

0.3-2.5mm ≤0.2Ω | 3.0-4.0mm≤0.5Ω

|

|

|

|

|

|

Standards

|

|||||||

|

Surface Resistivity

|

0.3-2.5mm ≤0.3Ω | 3.0-4.0mm≤0.5Ω

|

|

|

|

|

|

ASTM

F390

|

|||||||

|

Shielding Effectiveness

|

50-80dB(10MHz-3GHz)

|

|

|

|

|

|

ASTM

D4935

|

|||||||

|

Tensile

MPa

|

≥9.0

|

|

|

|

|

|

ASTMD

1000

|

|||||||

|

Suitable temperature

|

-20-100℃

|

|

|

|

|

|

Standards

|

|||||||

Nickel Shielding Black EMI Conductive Foam PE Conductive Foam

* Non-loose conductive fiber , no sharp edges, high elasticity and good consistency, conductive fixing adhesive, low surface contact resistance, no loss of shielding performance after 10,000 frictions, thin cross section suitable for base plate I/O and D-subminiature linings, can be used as grounding.

* It is widely used in PDP TV, LCD monitor, LCD TV, mobile phone, laptop computer, MP3, communication cabinet, medical instrument and other electronic products, as well as military and aerospace fields.