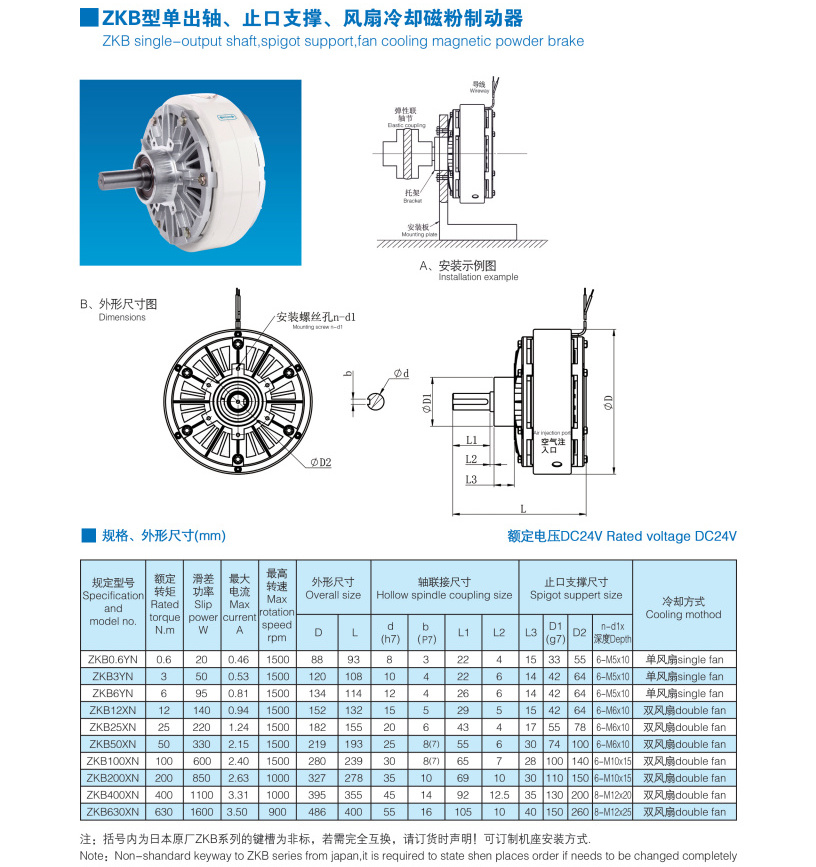

- Product Details

- {{item.text}}

Quick Details

-

Printing Type:

-

magnetic powder brake

-

Weight (KG):

-

20

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

MW

-

Application:

-

CNC Machine Center

-

Voltage:

-

24VDC

-

Rotating speed:

-

1800r/min

Quick Details

-

Condition:

-

New

-

Type:

-

magnetic powder brake

-

Use:

-

magnetic powder brake

-

Printing Type:

-

magnetic powder brake

-

Weight (KG):

-

20

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

MW

-

Application:

-

CNC Machine Center

-

Voltage:

-

24VDC

-

Rotating speed:

-

1800r/min

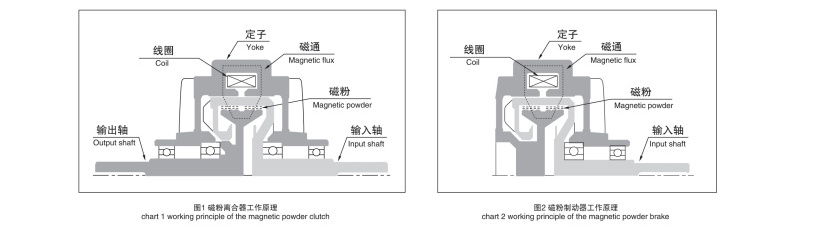

The magnetic power clutch is composed of active rotor (input shaft), driven rotor (out shaft) and Yoke with excitation coil. The three parts are assembled relative concentric and form a system which can rotate relatively. The annular gap between active rotor and driven rotor is full of alloy powder which has high magnetic conductivity.

The magnetic power will be in the state of loose when the current do not pass the excitation coil. The magnetic power will be thrown on the inner wall of active rotor. In this case, there will not exist the interaction force between the active and driven rotor. So the magnetic powder clutch is in the state of separation, no torque transmission exits.

The magnetic power in the working chamber will ink state under the action of the magnetic flux generated form the Yoke when the current pass the excitation coil. The magnetic powder clutch can transfer torque relying on the shear force generated from magnetic chain and the friction generated from the magnetic power and working face. In this case, the magnetic power clutch is in the state of combination

When the current is cut off, the magnetic flux will disappear with the disappearance of the magnetizing current, the magnetic powder will be in the state of loose under the action of gravity again, and will be thrown on the inner wall of active rotor under the action of the centrifugal force. In is case, the magnetic powder clutch will be in the state of separation again.

The magnetic powder clutch and brake have the same principle, the magnetic powder brake will form as long as the driven rotor of the magnetic powder clutch is fixed.

Advantages:

1, CNC precision manufacturing, high precision, precision machining, good linearity, superior performance.

2, magnetic powder high purity, no black powder, stable performance, long life.

3, aluminum alloy structure, with excellent heat dissipation performance, good demagnetization, fast response.

4. Stable operation, no vibration, no impact and no noise when starting, running and braking.