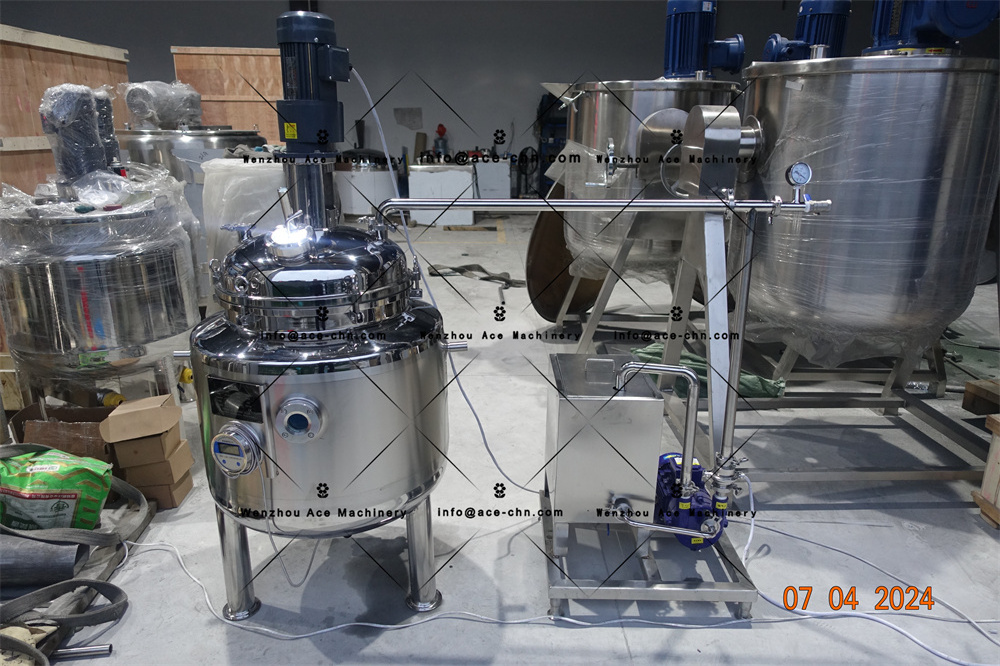

Complete process of dissolving, mixing, heating and cooling in one unit

Working capacity from 50L to 30000L

Variable speed for agitator

Double jackets for heating and cooling

Different jacket designs available for steam and electric heating

Double temperature probes and controllers for electrical heating in mixer tank

Vacuum system to take out the air bubbles during mixing and to transfer the ingredients

All contact parts are made of SS304/316L and mirror polished

Push buttons control panel for easy operation

- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

10000

-

Weight (KG):

-

500 KG

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ACE

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

6.5 kW

-

Marketing Type:

-

New Product 2023

-

Stirring Method:

-

Anchor type mixing stirrer and homogenizer

-

Mixing speed of stirrer:

-

0-65r.p.m

-

Mixing speed of homogenizer:

-

0-3000r.p.m

-

Internal surface Treatment:

-

Polishing

-

Heating method:

-

Electric or steam

-

Tags:

-

high shear/stainless steel/high speed

-

Machine Type:

-

Chemical Batch Reactor

-

Be suitable for:

-

Fluid, fruit juice, milk tea, shampoo, liquid soap etc.

-

Application scope:

-

Resin

-

Keywords:

-

Food Gel Emulsifier Homogenizer Making Machine

Quick Details

-

Barrel Volume (L):

-

1000

-

Max. Loading Volume (L):

-

5000 L

-

Range of Spindle Speed(r.p.m):

-

1 - 3000 r.p.m

-

Max. Loading Capacity:

-

10000

-

Weight (KG):

-

500 KG

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ACE

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

6.5 kW

-

Marketing Type:

-

New Product 2023

-

Stirring Method:

-

Anchor type mixing stirrer and homogenizer

-

Mixing speed of stirrer:

-

0-65r.p.m

-

Mixing speed of homogenizer:

-

0-3000r.p.m

-

Internal surface Treatment:

-

Polishing

-

Heating method:

-

Electric or steam

-

Tags:

-

high shear/stainless steel/high speed

-

Machine Type:

-

Chemical Batch Reactor

-

Be suitable for:

-

Fluid, fruit juice, milk tea, shampoo, liquid soap etc.

-

Application scope:

-

Resin

-

Keywords:

-

Food Gel Emulsifier Homogenizer Making Machine

Video

Products Description

Vacuum mixing tanks are commonly used in the food and beverage industry for various applications such as mixing, emulsifying, homogenizing, and dissolving ingredients. These tanks are designed to create a vacuum environment that can be used to remove air from the mixing chamber, which helps to prevent oxidation and spoilage of the ingredients. Here are some specific applications of vacuum mixing tanks in the food and beverage industry:

Mixing of ingredients

: It is used to mix ingredients together when making sauces, ketchup, jam, butter, mayonnaise, dressings, and margarine. The vacuum environment helps to prevent oxidation of the ingredients, resulting in a more uniform texture.

Emulsification

: Vacuum mixing tanks can be used to emulsify ingredients such as oil and water, which are typically difficult to mix together. By creating a vacuum environment, the ingredients can be mixed together more effectively, resulting in a smooth and stable emulsion. When making mayonnaise, custard sauce, is the most used.

Homogenization

: Vacuum mixing tanks can also be used for homogenization, which is the process of breaking down large particles into smaller ones. This is often used in the dairy industry to create a smooth and consistent texture in products such as milk and ice cream.

Ingredients dissolving

: When the high-speed agitator is equipped, vacuum mixing tanks are used to dissolve ingredients such as sugar or powder in liquids. The vacuum environment helps to speed up the dissolution process and also helps to prevent the formation of air bubbles.

Vacuum Mixing Tank: Key Features

We can customize according to your drawings, or we can provide you with design drawings according to your requirements.

|

Capacity

|

50-30,000L

(Can Be Customerized)

|

|

|

Mixing Power

|

0.75-15KW

|

|

|

Mixing Speed

|

0-60 (R/MIN)

|

|

|

Homogenizing power

|

2 .2-22 KW

|

|

|

Homogenizing speed

|

0-3600 RPM

|

|

|

Heating Mode

|

Steam heating or electric heating (optional)

|

|

|

Material

|

304 or 316 Stainless steel

|

|

|

Insulation

|

Single layer or with insulation

|

|

|

Top Head type

|

Dish top, Open lid top, Flat top

|

|

|

Bottom type

|

Dish bottom, Conical bottom, Flat bottom

|

|

|

Agitator type |

impeller, Anchor , Turbine , High shear, magnetic mixer, Anchor mixer with scraper

|

|

|

|

magnetic mixer, Anchor mixer with scraper

|

|

|

Inside Finsh

|

Mirror polished Ra<0.4um

|

|

|

Outside Finish

|

2B or Satin Finish

|

|

|

The parameters for reference ONLY, all the machines can be customized accordingly.

|

|

|

Details Images

Packaging & Shipping

We are experienced in the whole packing and shipping process,and we will be responsible for any damage made during shipping and send clients replacements for free.

* Sufficient inner protection with different materials, including bubble bag, foam board and others.

* Qualified wooden package or carton for different products or as customer require

* Strict packing process to ensure the safety and completeness of the goods

Certifications

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in a plywood case or carton package for small parts.

If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What are your terms of payment?

A: T/T in advance, 30% as deposit, and finish 70% balance payment before delivery.

We'll show you the photos of the products and packages before you pay the balance.

Q3. What are your terms of delivery?

A: EXW, FOB, CIF, DDU.

Q4. How about your delivery time?

A: Generally, it will take 3 to 4 weeks after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend, and we sincerely do business and make friends with them, no matter where they come from.

Mayonnaise Making Processing Machine Homogenizer Emulsifier

Mayonnaise Equipment Mayonnaise Production Line Mayonnaise Mixing Machine for sale

Contact Us

Hot Searches