1. Sediment:

Waste oil or pyrolysis oil will be collected and stored in big tanks, make the big size impurities sink to the bottom, when loading , leave the bottom impurities.

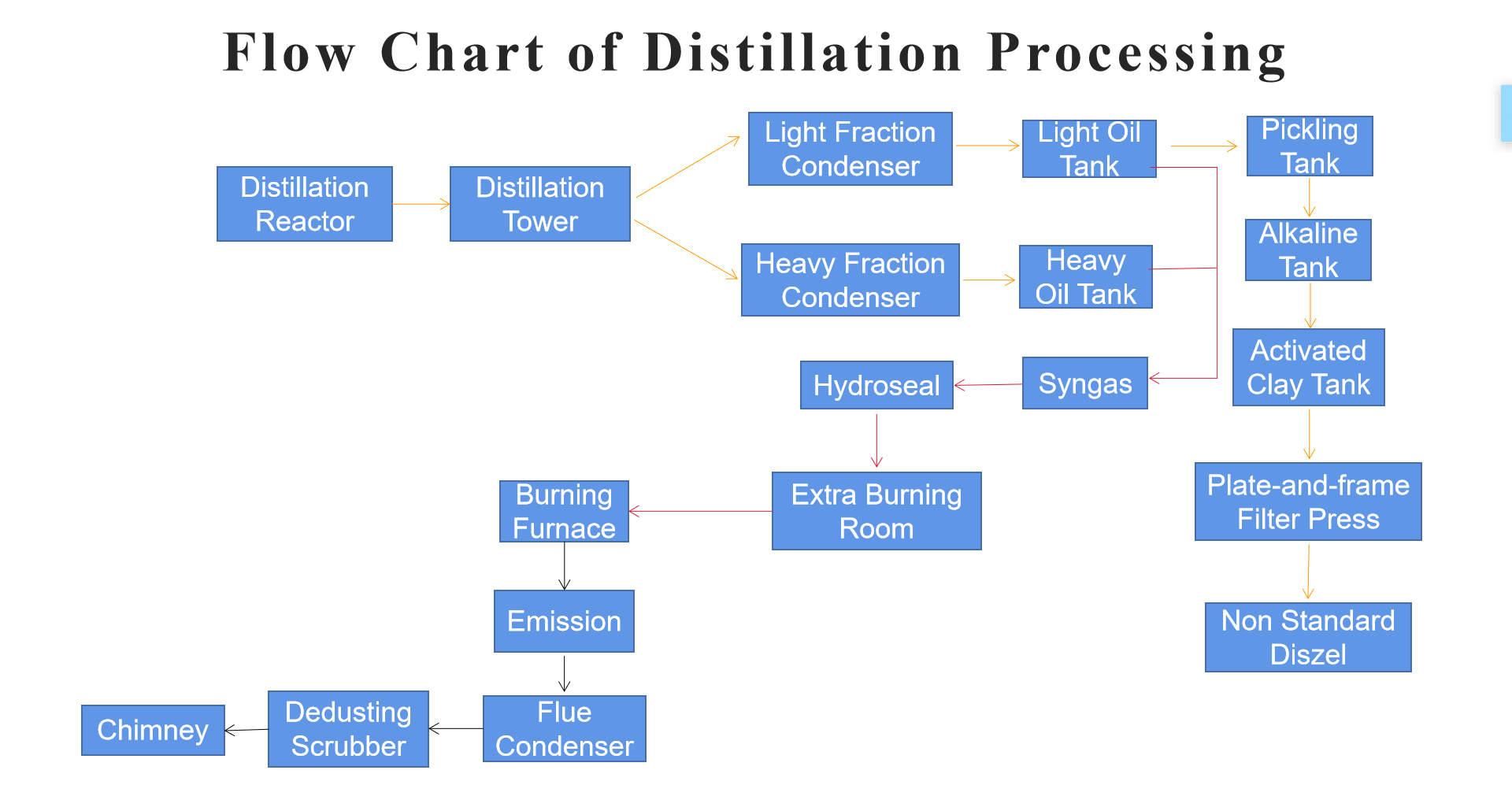

2. Distillation:

Pumping the oil into the distillation reactor, and start heating, highest temperature in the system should be around 350 ℃, under vacuum production environment, to keep safety of operation, liquid oil heated to become oil gas, then condensed into liquid oil again and stored in the oil tank, this process help to separate light oil from the impurities.

3. Acid washing:

Acid washing is to mix a fix quantity of H2SO4 with the oil, to make the impurities precipitate out, to improve the color and smell of the oil, the concentration of the H2SO4 should be more than 98%, Concentrated sulfuric acid has strong oxidizing property, could generate sulfonation, oxidation, esterification with the nitrogen, oxygen, sulphur containing compounds, thus, this process also has very obvious function to remove the sulphur in the oil.

4. Alkaline Washing:

The main purpose of Alkaline washing to neutralize the acid in the oil, the make the PH of oil to be 7.

5. Activated clay treatment:

Activated clay has strong chemical and physical adsorption function to the impurities, which will help to improve the color of the oil and make it more stable.

6. Filter press:

Filter process is to separate the impurities in the oil by pressing the oil through filter cloth, the oil will be cleaner after this process.