- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Haidike

-

Voltage:

-

220V,50-60Hz

-

Dimension(L*W*H):

-

910*1090*990mm

-

Weight:

-

183 kg

-

Marketing Type:

-

New Product 2023

-

PLC Brand:

-

NON PLC, OTHER

-

Function:

-

Slitting Rewinding Paper Roll

-

Cutting length(mm):

-

0.1-99999.9mm

-

Cutting speed:

-

30-160pcs/min

-

Cutting thickness:

-

0-2mm

-

Feeding width:

-

1-800mm

-

Cutting precision:

-

0.1mm

-

Feeding motor:

-

stepper motor

-

Cutter motor:

-

AC motor

-

Cutter material:

-

High-speed steel

-

After Warranty Service:

-

Video technical support

Quick Details

-

Type:

-

Paper Cutting Machine

-

Production Capacity:

-

160 m/min

-

Max. workable width:

-

800mm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Haidike

-

Voltage:

-

220V,50-60Hz

-

Dimension(L*W*H):

-

910*1090*990mm

-

Weight:

-

183 kg

-

Marketing Type:

-

New Product 2023

-

PLC Brand:

-

NON PLC, OTHER

-

Function:

-

Slitting Rewinding Paper Roll

-

Cutting length(mm):

-

0.1-99999.9mm

-

Cutting speed:

-

30-160pcs/min

-

Cutting thickness:

-

0-2mm

-

Feeding width:

-

1-800mm

-

Cutting precision:

-

0.1mm

-

Feeding motor:

-

stepper motor

-

Cutter motor:

-

AC motor

-

Cutter material:

-

High-speed steel

-

After Warranty Service:

-

Video technical support

Products Description

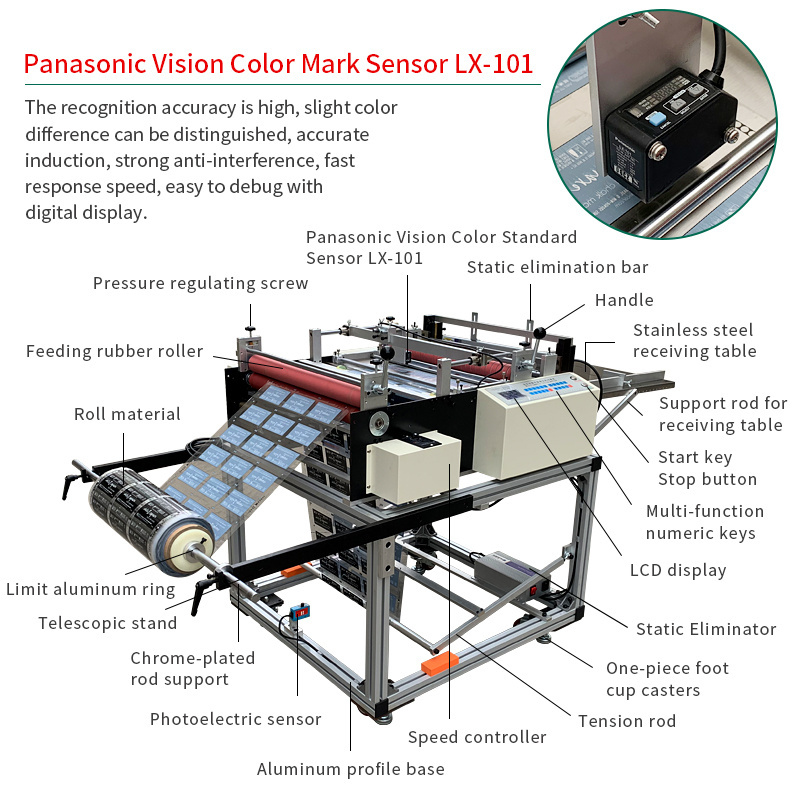

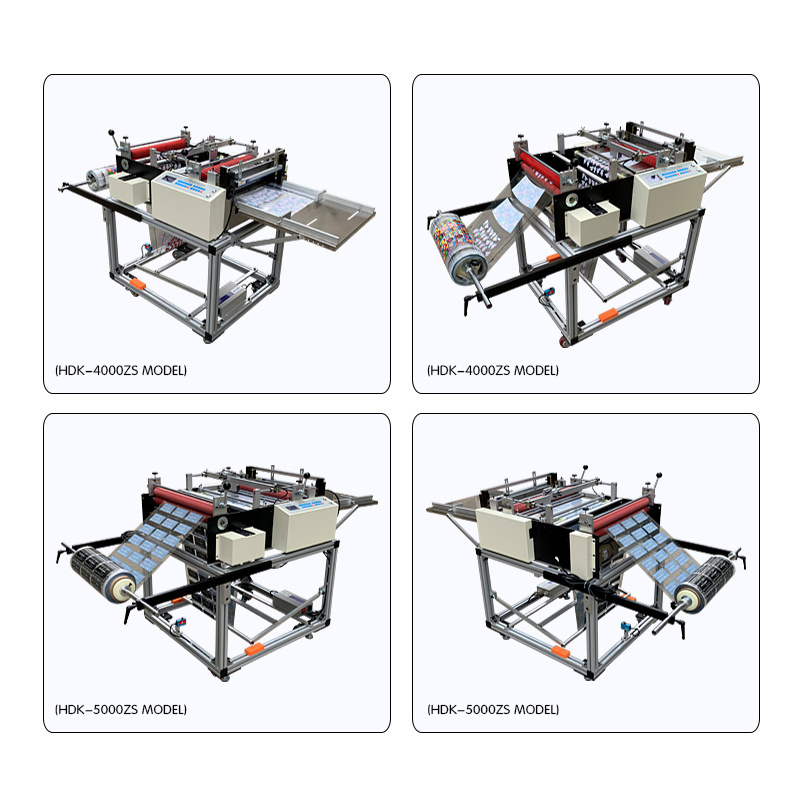

Fully Automatic Paper Roll To Sheet Cutter A4 Size Paper Cutting Machine Film Cutter For Foil

|

Product name

|

Plastic Film Paper Cutting Machine

|

|

|

|

|||

|

Product model

|

HDK-800ZS

|

|

|

|

|||

|

Power supply

|

220V 50/60Hz

|

|

|

|

|||

|

Cutting length(mm)

|

0.1-99999.9mm

|

|

|

|

|||

|

Cutting speed

|

30-160pcs/min

|

|

|

|

|||

|

Feeding width

|

1-800mm

|

|

|

|

|||

|

Cutting precision

|

0.1mm

|

|

|

|

|||

|

Weight

|

183kg

|

|

|

|

|||

|

Size (L×W×H)

|

910*1090*990(mm)

|

|

|

|

|||

|

Feeding motor

|

Stepper motor

|

|

|

|

|||

|

Cutter motor

|

AC motor

|

|

|

|

|||

|

Cutter material

|

High-speed steel

|

|

|

|

|||

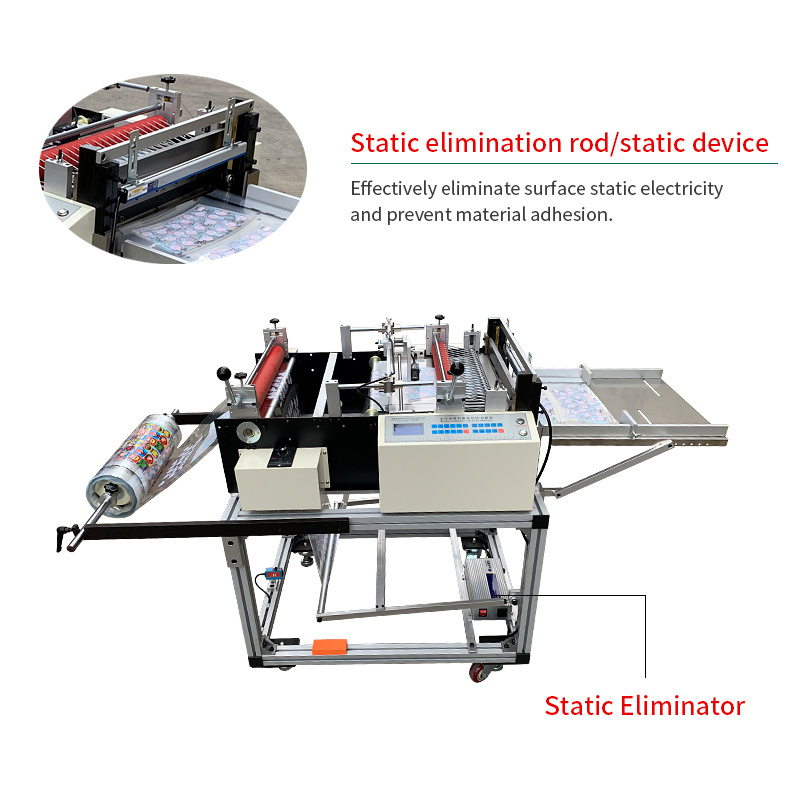

Features:

1,All kinds of film, cloth, paper and other roll materials can be cut.

2,The adjustable speed motor cooperates with the photoelectric sensor to realize automatic unwinding and synchronous cutting with

faster speed, higher efficiency and more accurate precision.

3,The machine is compact in design and smaller in size. It can be moved and installed at any time with all-in-one foot cup

casters.

4,The spring-type feeding mechanism is used with an angle-adjustable material receiving table, which can receive materials neatly

regardless of thickness and save labor.

5,Humanized design, simple operation, stable performance and easy maintenance.

2,The adjustable speed motor cooperates with the photoelectric sensor to realize automatic unwinding and synchronous cutting with

faster speed, higher efficiency and more accurate precision.

3,The machine is compact in design and smaller in size. It can be moved and installed at any time with all-in-one foot cup

casters.

4,The spring-type feeding mechanism is used with an angle-adjustable material receiving table, which can receive materials neatly

regardless of thickness and save labor.

5,Humanized design, simple operation, stable performance and easy maintenance.

Product principle:

1. Automatic group accumulation and total cumulative count

2. Batch pause and delay time can be set

3. There are various manual operations for debugging

4. Can automatically cut all kinds of strips, sheets, plastic tubes and other materials

5. High-speed feeding, controlled by microcomputer program with an accuracy of 0.1mm

6. High-speed stepping motor accurately controls cutting length and speed

7. Cutting time protection; total setting; sub-setting; adjustable timeout

8. The cutter speed is adjustable, all Chinese LCD display, export or foreign companies can be customized English version

9. The length and speed are arbitrarily adjustable, fully automatic cutting and automatic feeding, completely liberating labor

10.LCD large screen intuitive Chinese display, simple and convenient operation; using special mechanical structure and special

tools,With special software control, it solves the problem of uneven cutting in other manufacturers, reaching the level of the

slit and the length

11. Fast feeding speed, high cutting force, high cutting efficiency, stable performance, cutting all kinds of hard and thick

materials, high cutting precision and straight cut

12. Add unwinding motor and induction photoelectric, which can realize synchronous unwinding, solve the problem of slow feeding

speed and poor precision of heavy coils.

2. Batch pause and delay time can be set

3. There are various manual operations for debugging

4. Can automatically cut all kinds of strips, sheets, plastic tubes and other materials

5. High-speed feeding, controlled by microcomputer program with an accuracy of 0.1mm

6. High-speed stepping motor accurately controls cutting length and speed

7. Cutting time protection; total setting; sub-setting; adjustable timeout

8. The cutter speed is adjustable, all Chinese LCD display, export or foreign companies can be customized English version

9. The length and speed are arbitrarily adjustable, fully automatic cutting and automatic feeding, completely liberating labor

10.LCD large screen intuitive Chinese display, simple and convenient operation; using special mechanical structure and special

tools,With special software control, it solves the problem of uneven cutting in other manufacturers, reaching the level of the

slit and the length

11. Fast feeding speed, high cutting force, high cutting efficiency, stable performance, cutting all kinds of hard and thick

materials, high cutting precision and straight cut

12. Add unwinding motor and induction photoelectric, which can realize synchronous unwinding, solve the problem of slow feeding

speed and poor precision of heavy coils.

Material Application

Suitable for cutting various PET protective films, reflective films, OPP films, PVC films, PE electrostatic films, ITO films,

plastic films, heat shrinkable films, hot melt adhesive films, thermoplastic films, thermal transfer films, release films,

non-woven fabrics, flocked fabrics, knitted fabrics, non-woven, abrasive gauze, leather, laundry pieces, self-adhesive paper,

insulating paper, release paper, highland barley paper, toilet paper, wrapping paper, roll paper, double-sided tape, copper foil,

aluminum foil, tin paper, EVA foam, pearl cotton and other roll materials.

plastic films, heat shrinkable films, hot melt adhesive films, thermoplastic films, thermal transfer films, release films,

non-woven fabrics, flocked fabrics, knitted fabrics, non-woven, abrasive gauze, leather, laundry pieces, self-adhesive paper,

insulating paper, release paper, highland barley paper, toilet paper, wrapping paper, roll paper, double-sided tape, copper foil,

aluminum foil, tin paper, EVA foam, pearl cotton and other roll materials.

Product packaging

Hot Searches