- Product Details

- {{item.text}}

Quick Details

-

Vibrating Amplitude:

-

2-5mm

-

Length of Flexible Shaft:

-

le Shaft: 1-2m

-

Voltage:

-

220v

-

Weight:

-

500 kg

-

Dimension(L*W*H):

-

2000*1000*700

-

Product name:

-

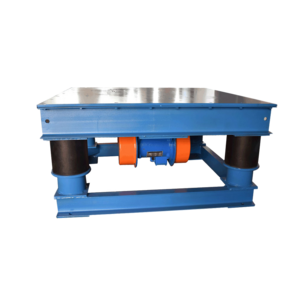

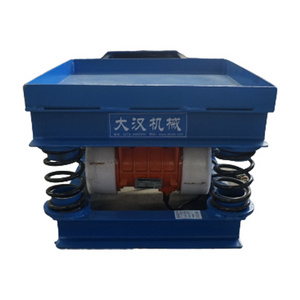

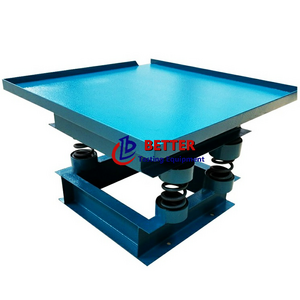

Concrete cement precast paver small shaker vibrating table

-

Color:

-

Custom colors

-

Usage:

-

Interlocking pavers or tiles making vibration table

-

Product Keywords:

-

vibration table

-

Feature:

-

Durable

-

Size:

-

2000*1000*600mm

-

certification:

-

ISO9001

-

automatic:

-

Yes

-

brand name:

-

HTX

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HTX

-

Frequency:

-

50/60HZ

-

Vibrating Amplitude:

-

2-5mm

-

Length of Flexible Shaft:

-

le Shaft: 1-2m

-

Voltage:

-

220v

-

Weight:

-

500 kg

-

Dimension(L*W*H):

-

2000*1000*700

-

Product name:

-

Concrete cement precast paver small shaker vibrating table

-

Color:

-

Custom colors

-

Usage:

-

Interlocking pavers or tiles making vibration table

-

Product Keywords:

-

vibration table

-

Feature:

-

Durable

-

Size:

-

2000*1000*600mm

-

certification:

-

ISO9001

-

automatic:

-

Yes

-

brand name:

-

HTX

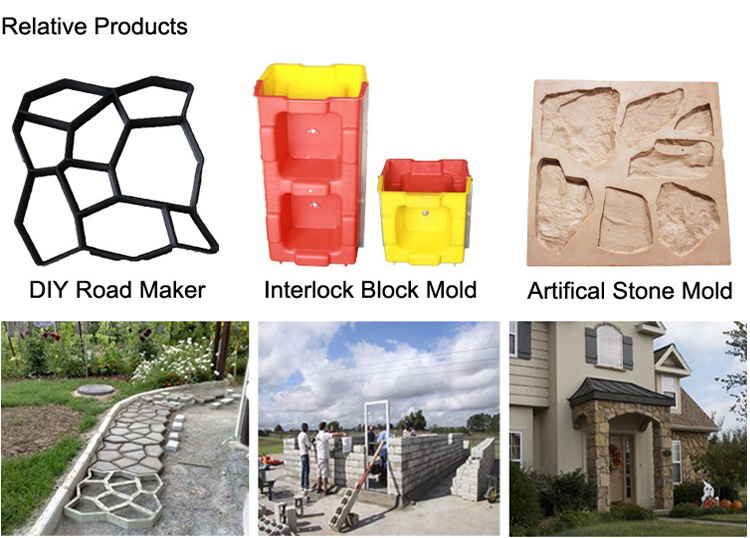

Plastic paver moulds vibrator table for concrete paver

Our vibrating table adopt the 1.53kw GB standerd virating motors with simple structure,lower cost for investment,it is a best choice for the street paver,curb ,interlocking tiles and other concrete product making.

Working process:

1.Rall material(concrete)

2.Pan mixer

3.Concrete in the plastic moulds

4.vibrating on the table

5.Final pavers .

Technical Parameters

| Specification Model | Exterior dimension(mm) | Powe(KW) | vibrating capacity(T) |

| HTXMP-2000 | 2000*1000*700 | 1.5 | 1—2 |

| HTXMP-2500 | 2500*1000*700 | 2 | 1—2 |

| HTXMP-3000 | 3000*1000*700 | 3 | 1—2 |

The details of the concrete pavers vibrating table

Vibrating table instructions

1.Installation:

a. Before installation,check the vibrating motor whether it is loose or not,then make table foot fix on the pre-concrete foundation,note that one side higher a little,and another sie should be lower a little.Slope degree=5-60,then the moulds will move from the top side to lower one.

b. Link the wire(A,B,C ,3 phases) with motor in the right way,prohibit the motor reverse rotation,if happened,stop at once and change wire linking until right rotation.

Our vibrating table production line and plastic moulds has been exported to many countries,like Kenya,Ethiopia,Ghana,Oman,Iraq ,Srilanka,Pakistan etc,by its own lower investment,simple working process,and strong quality,we are winning more and more orders.