- Product Details

- {{item.text}}

Quick Details

-

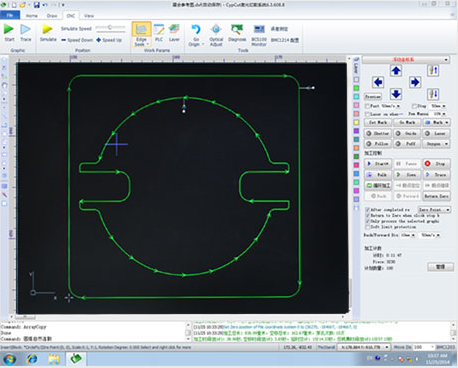

Control System Brand:

-

Cypcut

-

Cutting Area:

-

4000*2000mm

-

Cutting Thickness:

-

0.5~20mm

-

Control Software:

-

CYPCUT

-

Place of Origin:

-

Shandong, China

-

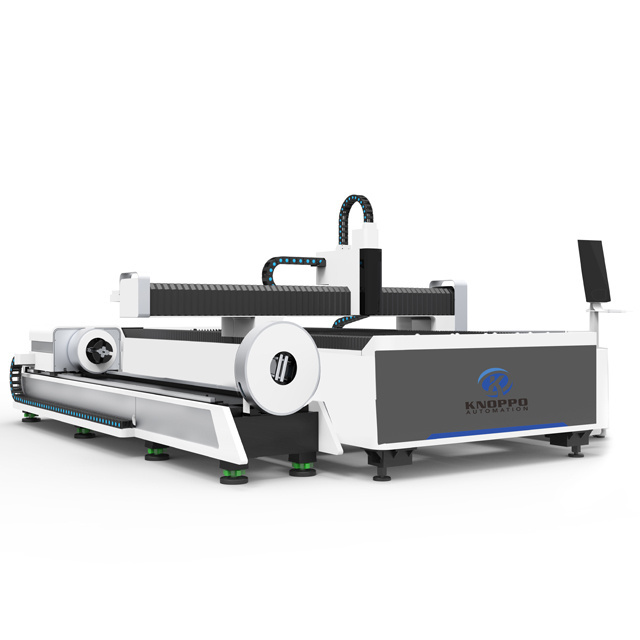

Brand Name:

-

KNOPPO

-

Weight (KG):

-

8100 KG

-

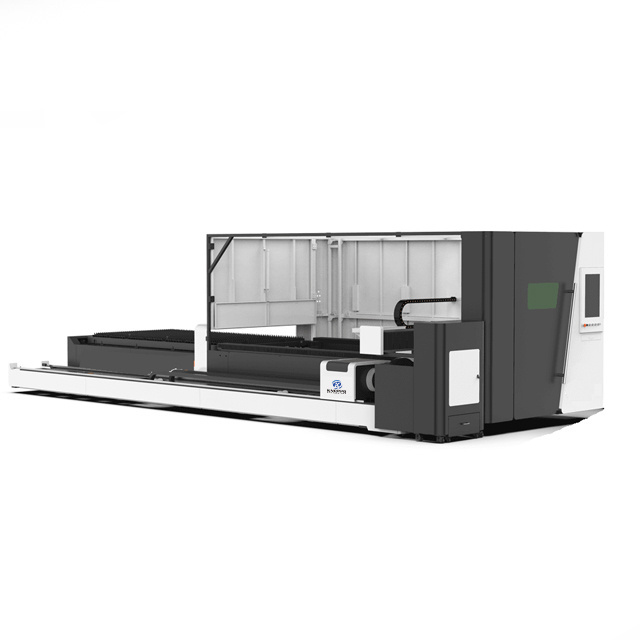

Product name:

-

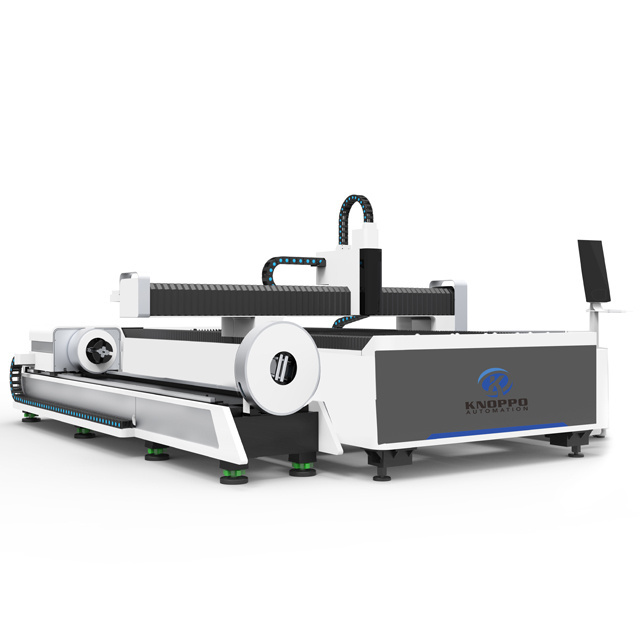

Fiber laser cutting machine sheet metal and tube

-

Working area:

-

4000*2000mm

-

Machine overall dimensions:

-

5600*4000*2000mm/8400*4000*2000mm

-

Machine weight:

-

7500kg/8100kg

-

Laser Head:

-

Switzerland Raytools

-

Laser Source:

-

MAX

-

Control System:

-

CYPCUT

-

Motor:

-

Japan Yaskawa

-

Driver:

-

Japan Yaskawa

-

Water Chiller:

-

S&A

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

10m/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

4000*2000mm

-

Cutting Thickness:

-

0.5~20mm

-

Control Software:

-

CYPCUT

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

KNOPPO

-

Weight (KG):

-

8100 KG

-

Product name:

-

Fiber laser cutting machine sheet metal and tube

-

Working area:

-

4000*2000mm

-

Machine overall dimensions:

-

5600*4000*2000mm/8400*4000*2000mm

-

Machine weight:

-

7500kg/8100kg

-

Laser Head:

-

Switzerland Raytools

-

Laser Source:

-

MAX

-

Control System:

-

CYPCUT

-

Motor:

-

Japan Yaskawa

-

Driver:

-

Japan Yaskawa

-

Water Chiller:

-

S&A

|

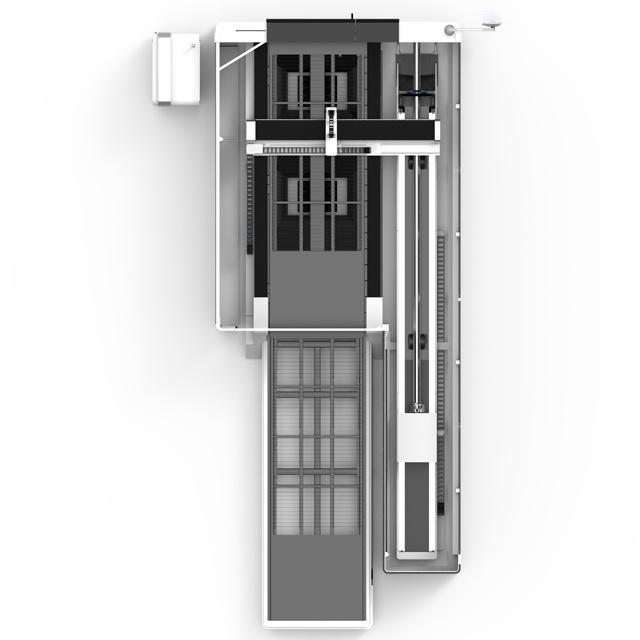

Model

|

|

KF4020T

|

|

|

|||

|

Laser Power

|

|

1000W/1500W/2000W/3000W/4000W/6000W

|

|

|

|||

|

Working area

|

|

3000*1500mm / 4000*2000mm / 6000*2000mm/6000*2500mm

|

|

|

|||

|

Machine overall dimensions

|

|

KF-T3:5600*4000*2000mm

KF-T6:8400*4000*2000mm |

|

|

|||

|

Machine weight

|

|

KF-T3:7500kg

KF-T6:8100kg |

|

|

|||

|

Max. linkage speed

|

|

100m/min

|

|

|

|||

|

Max. acceleration

|

|

1G

|

|

|

|||

|

Positioning accuracy

|

|

0.05mm

|

|

|

|||

|

Repositioning accuracy

|

|

0.03mm

|

|

|

|||

|

Tube Cutting Length

|

|

3m / 6m

|

|

|

|||

|

Tube Cutting Diameter

|

|

φ20~φ220mm /φ16-φ150mm

|

|

|

|||

|

Laser Head

|

|

Switzerland Raytools

|

|

|

|||

|

Laser Source

|

|

MAX

|

|

|

|||

|

Servo motor and driver

|

|

Japan Yaskawa

|

|

|

|||

-

MAX Laser Source

2. X,Y,Z axis high power motor drive, acceleration up to 1.5G.

Knoppo Automation is one of the world’s leading manufacturers of high-tech industrial laser solutions, dedicated to providing laser intelligent equipment solutions and enabling our customers in various branches around the world to become more efficient and competitive. With more than 15,000 laser cutting systems in the market and a rapidly increasing global base, Knoppo Automation is in a favorable position to serve the international customer base, guaranteeing highest quality and shortest response times in already more than 100 countries. Our focus is on the innovation, continuous improvement and rapid development of technologies, all of which aim to increase efficiencies and flexibility, minimize costs while generating the highest levels of environmental friendliness and sustainability to our all benefit. We aim to provide key technologies and customized integration solutions for Industry 4.0 and smart factories, helping enterprises to make perfect use of the many opportunities arising in the digital age.

The product range not only comprises of flat sheet cutting systems in various designs and dimensions, but also of laser tube cutting systems, CO2 laser cutting engraving machine , laser marking machine etc . With our focused, highly skilled and experienced R & D team and a perfectly equipped and trained systematic after-sales technical department, we truly provide customer-oriented service experience. Cheap Raycus Small Fiber Laser Cutting Machine.