- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

0.5%(Please send us your enquiry for details)

-

Voltage:

-

220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LIENM

-

Weight:

-

500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Inner Heating Type Tube Filling Sealing Machine

-

Capacity:

-

30-80 tubes/min

-

Tube diameter:

-

10-55mm

-

Filling volume:

-

2-250ml

-

Tube lenth:

-

50-220mm

-

Usage:

-

Ointment, cream, gel and viscosity fluid,etc.

-

Heating mode:

-

Inner Heating

-

Market:

-

Africa, Asia, Australia, Europe,USA,etc

-

Marketing Type:

-

Hot Product

Quick Details

-

Machinery Capacity:

-

4000BPH, Other, 6000BPH, 2000BPH, 1000BPH

-

Packaging Material:

-

Plastic, Wood

-

Filling Material:

-

Other, Water, Cosmetic

-

Filling Accuracy:

-

0.5%(Please send us your enquiry for details)

-

Voltage:

-

220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LIENM

-

Weight:

-

500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Inner Heating Type Tube Filling Sealing Machine

-

Capacity:

-

30-80 tubes/min

-

Tube diameter:

-

10-55mm

-

Filling volume:

-

2-250ml

-

Tube lenth:

-

50-220mm

-

Usage:

-

Ointment, cream, gel and viscosity fluid,etc.

-

Heating mode:

-

Inner Heating

-

Market:

-

Africa, Asia, Australia, Europe,USA,etc

-

Marketing Type:

-

Hot Product

Product Description

Working principle

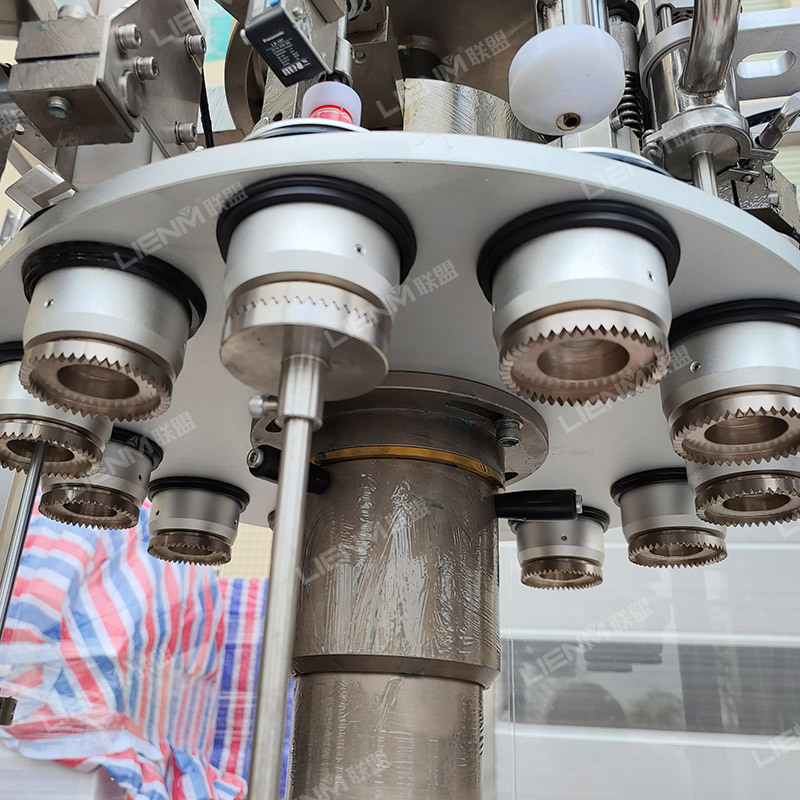

The hose is placed neatly in the large-capacity pipe hopper. After the automatic feeding device, the hose is automatically inserted into the positioning die after being aligned, and the positioning die rotates with the turntable and stays at different working positions. The paste to be filled is put into a closable conical barrel, and the piston type quantitative filling valve directly connected with the barrel is accurately and automatically injected into the empty tube intermittently staying at the filling station, and the large tray continues to rotate. The hose that has been filled with the paste is quickly taken to the flattening station, and then transferred to the mechanical manual position to seal the aluminum tube and complete the coding.

structural characteristics

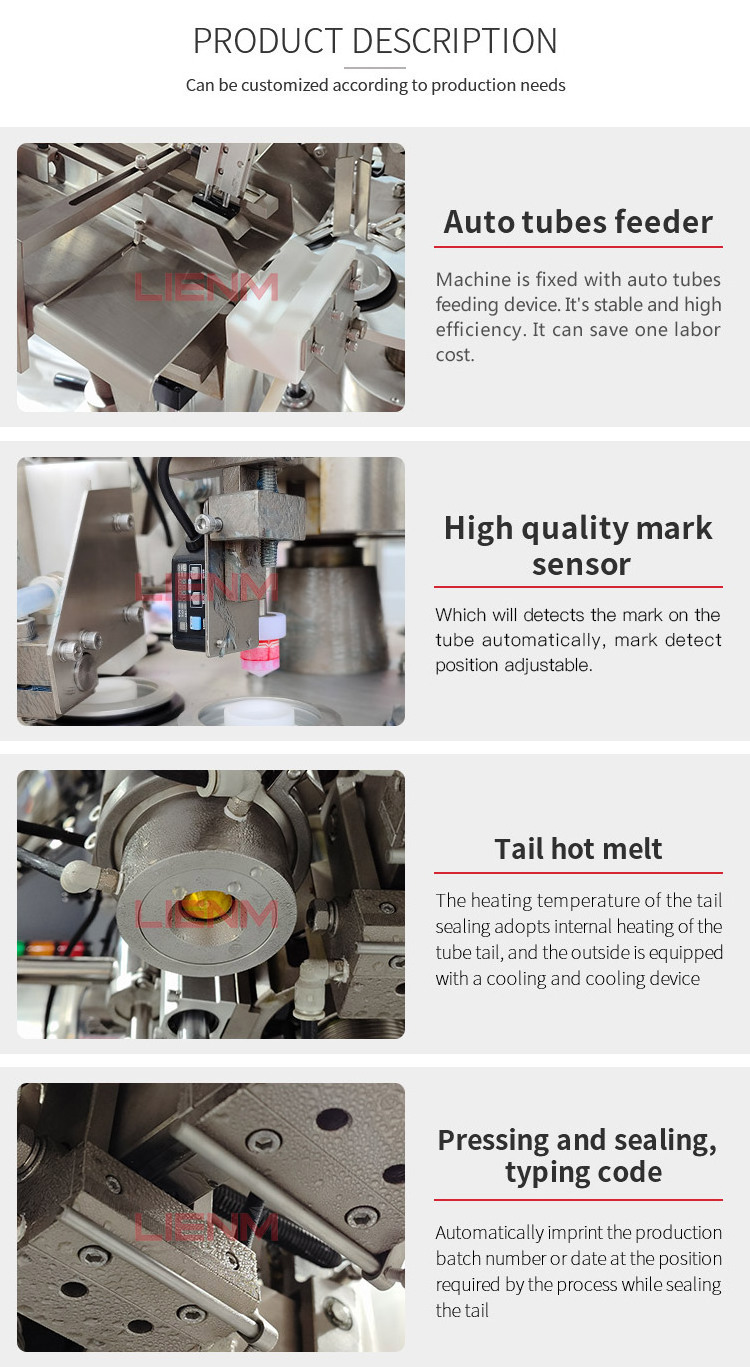

(1) Structural design This machine fully reflects the advanced design, reliability and rationality of GMP requirements for pharmaceutical equipment, pays attention to people-oriented, and reduces the human factors in the process of equipment use. Automatic feeding of the tube, automatic positioning of the tube direction, filling, sealing, batch numbering, finished product exit, using linkage design, all actions are completed simultaneously.

(2) Intuitive operation of equipment The setting of the heating temperature, the production speed of the equipment, the fault display, the completion workload, etc. are directly displayed on the operation panel, and the adjustment of the working parameters of the equipment can be directly performed on the panel. The operation panel is equipped with plexiglass, and the overall open design of the equipment allows the operator to easily observe the operation of the inspection equipment at any time.

(3) The function is easy to adjust the tail structure The machine can directly complete the heat sealing and sealing of the whole plastic pipe and composite pipe, and the two sides of the metal pipe such as the aluminum pipe, the three-side folding tail and the saddle-shaped folding edge sealing work. The shape and size of the seal can be adjusted conveniently and accurately according to the needs of the user.

(4) Fully meet the requirements of medicines and cosmetics for filling process The machine is compact and can be used up to 1S from filling to sealing, and can be used in complex sealing forms.

The hose is placed neatly in the large-capacity pipe hopper. After the automatic feeding device, the hose is automatically inserted into the positioning die after being aligned, and the positioning die rotates with the turntable and stays at different working positions. The paste to be filled is put into a closable conical barrel, and the piston type quantitative filling valve directly connected with the barrel is accurately and automatically injected into the empty tube intermittently staying at the filling station, and the large tray continues to rotate. The hose that has been filled with the paste is quickly taken to the flattening station, and then transferred to the mechanical manual position to seal the aluminum tube and complete the coding.

structural characteristics

(1) Structural design This machine fully reflects the advanced design, reliability and rationality of GMP requirements for pharmaceutical equipment, pays attention to people-oriented, and reduces the human factors in the process of equipment use. Automatic feeding of the tube, automatic positioning of the tube direction, filling, sealing, batch numbering, finished product exit, using linkage design, all actions are completed simultaneously.

(2) Intuitive operation of equipment The setting of the heating temperature, the production speed of the equipment, the fault display, the completion workload, etc. are directly displayed on the operation panel, and the adjustment of the working parameters of the equipment can be directly performed on the panel. The operation panel is equipped with plexiglass, and the overall open design of the equipment allows the operator to easily observe the operation of the inspection equipment at any time.

(3) The function is easy to adjust the tail structure The machine can directly complete the heat sealing and sealing of the whole plastic pipe and composite pipe, and the two sides of the metal pipe such as the aluminum pipe, the three-side folding tail and the saddle-shaped folding edge sealing work. The shape and size of the seal can be adjusted conveniently and accurately according to the needs of the user.

(4) Fully meet the requirements of medicines and cosmetics for filling process The machine is compact and can be used up to 1S from filling to sealing, and can be used in complex sealing forms.

(5)The running part of the sealing manipulator adopts the Japanese guide rail. The self-lubricating bearing is adopted on the sliding shaft on the upper and lower sides of the claw. The transmission is reliable, no vibration and noise are generated, and no pollution occurs.

(6) The automatic filling and sealing machine adopts the frequency conversion stepless speed regulation system, and the working operation implements coordinated linkage control, which can obtain higher production speed. The pneumatic control system sets the precision filter and maintains a certain stable pressure.

(7) The safety clutch is set on the main drive system, which can effectively realize the fault overload protection.

(8) High efficiency and energy-saving production capacity The machine has reliable transmission system, high filling precision, advanced sealing form and effective production capacity.

(9) Beautiful appearance and easy to clean The machine has beautiful appearance, stainless steel polishing and refining, compact structure, easy to clean the table top, and fully meets the GMP requirements for pharmaceutical production.

(6) The automatic filling and sealing machine adopts the frequency conversion stepless speed regulation system, and the working operation implements coordinated linkage control, which can obtain higher production speed. The pneumatic control system sets the precision filter and maintains a certain stable pressure.

(7) The safety clutch is set on the main drive system, which can effectively realize the fault overload protection.

(8) High efficiency and energy-saving production capacity The machine has reliable transmission system, high filling precision, advanced sealing form and effective production capacity.

(9) Beautiful appearance and easy to clean The machine has beautiful appearance, stainless steel polishing and refining, compact structure, easy to clean the table top, and fully meets the GMP requirements for pharmaceutical production.

|

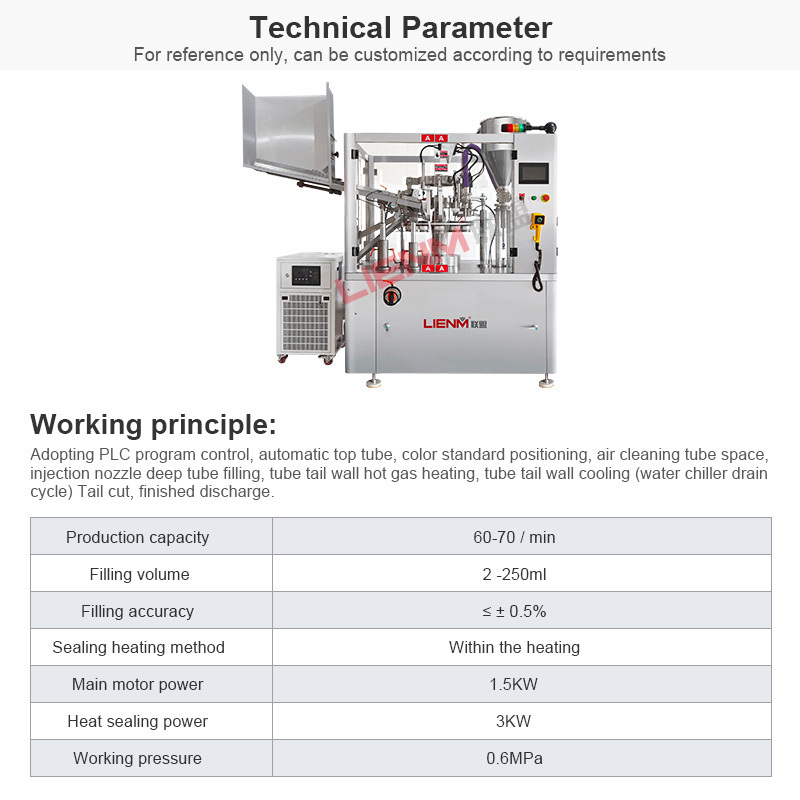

Main technical parameters

|

|

|

|

hose material

|

metal tube

|

|

|

Filling range

|

5ml-200ml/piece (adjustable)

|

|

|

Filling accuracy

|

≤±1%

|

|

|

operating speed

|

30-40 / min

|

|

|

hose diameter

|

Φ13-Φ35mm

|

|

|

hose length

|

200mm

|

|

|

200mm

|

380V (optional)

|

|

|

working pressure

|

0.55-0.65Mpa

|

|

|

matching motor

|

1.5kw

|

|

|

Dimensions

|

1500 × 1000 × 2000mm

|

|

|

Machine weight

|

800kg

|

|

Other Types

Recommend Products

Hot Searches